The Benefits of Using polyurethane Deck Dewatering in Manufacturing Processes

Polyurethane deck dewatering is a process that has gained popularity in the manufacturing industry due to its numerous benefits. This article will explore the advantages of using polyurethane deck dewatering in manufacturing processes.

One of the main benefits of polyurethane deck dewatering is its ability to effectively remove moisture from materials. Moisture can be a significant problem in manufacturing, as it can lead to product defects and decreased quality. By using polyurethane deck dewatering, manufacturers can ensure that their materials are free from excess moisture, resulting in higher quality products.

Another advantage of polyurethane deck dewatering is its versatility. It can be used with a wide range of materials, including plastics, metals, and textiles. This makes it an ideal choice for manufacturers who work with different types of materials. Whether it’s removing moisture from plastic pellets or drying fabric, polyurethane deck dewatering can handle the task effectively.

In addition to its versatility, polyurethane deck dewatering is also known for its efficiency. The process is quick and can be completed in a relatively short amount of time. This is especially beneficial for manufacturers who have tight production schedules and need to minimize downtime. With polyurethane deck dewatering, materials can be dried efficiently, allowing for faster production and increased productivity.

Furthermore, polyurethane deck dewatering is a cost-effective solution for manufacturers. Traditional methods of drying materials, such as air drying or using heat, can be expensive and time-consuming. Polyurethane deck dewatering, on the other hand, requires minimal energy and resources, making it a more economical choice. By reducing energy consumption and production costs, manufacturers can save money in the long run.

Polyurethane deck dewatering also offers environmental benefits. As mentioned earlier, the process requires minimal energy, which means it has a lower carbon footprint compared to other drying methods. Additionally, polyurethane is a recyclable material, further reducing its impact on the environment. By choosing polyurethane deck dewatering, manufacturers can contribute to sustainable manufacturing practices.

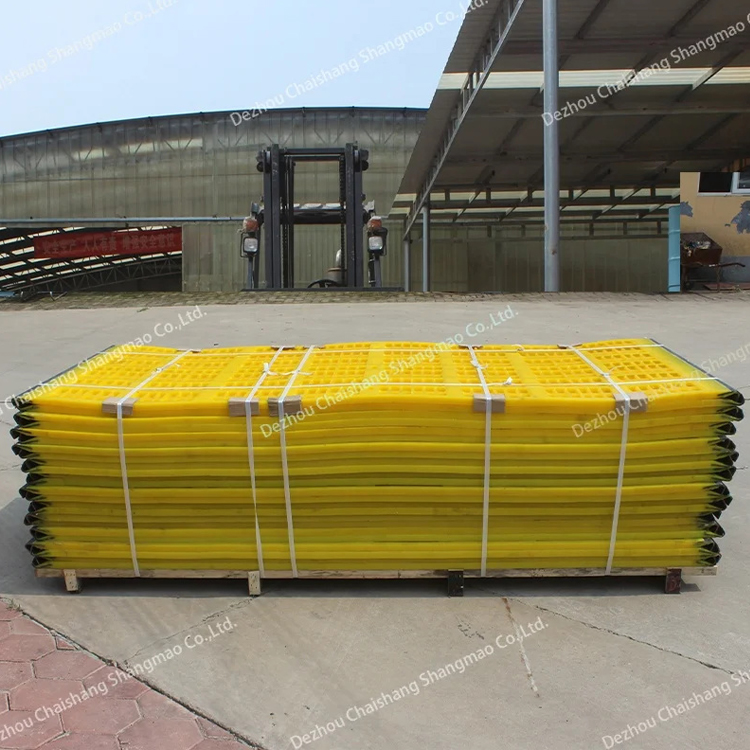

Another advantage of polyurethane deck dewatering is its durability. Polyurethane is a strong and resilient material that can withstand harsh conditions. This makes it suitable for use in manufacturing processes that involve heavy machinery or abrasive materials. With polyurethane deck dewatering, manufacturers can ensure that their equipment and materials are protected from damage, resulting in longer-lasting and more reliable products.

Lastly, polyurethane deck dewatering offers improved safety in manufacturing processes. Excess moisture can create slippery surfaces, increasing the risk of accidents and injuries. By effectively removing moisture from materials, polyurethane deck dewatering helps create a safer working environment for employees. This not only protects workers but also reduces the likelihood of product defects caused by accidents.

In conclusion, polyurethane deck dewatering offers numerous benefits for manufacturers. From its ability to remove moisture effectively to its versatility and cost-effectiveness, polyurethane deck dewatering is a valuable tool in the manufacturing industry. Its environmental benefits, durability, and improved safety further enhance its appeal. By incorporating polyurethane deck dewatering into their processes, manufacturers can achieve higher quality products, increased productivity, and a more sustainable approach to manufacturing.