How urethane Tensioned Sieve OEM Aggregate and Factory Vibrating polyurethane Fine Plate Can Improve Your Production Process

Urethane tensioned sieve OEM aggregate and factory vibrating polyurethane fine plate can improve your production process in a number of ways. Compared to traditional sieves, urethane tensioned sieves offer superior performance in terms of durability, efficiency, and cost-effectiveness.

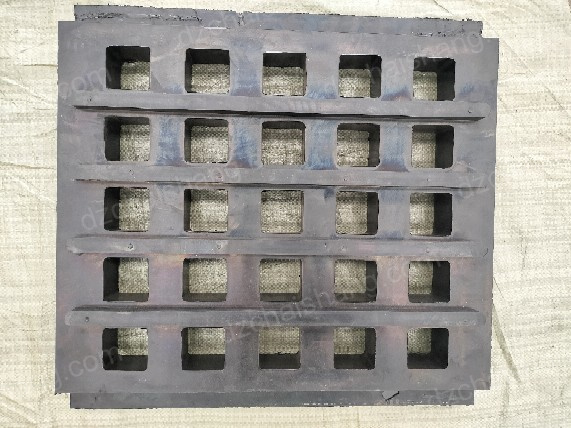

Urethane tensioned sieves are designed to be more durable than traditional sieves, as they are made from a high-grade polyurethane material that is resistant to wear and tear. This makes them ideal for use in harsh industrial environments, as they can withstand the rigors of heavy-duty production processes. Additionally, the tensioned design of the sieves ensures that they remain securely in place, even when subjected to high levels of vibration.

The efficiency of urethane tensioned sieves is also improved compared to traditional sieves. The tensioned design of the sieves allows them to be more effective at separating particles of different sizes, as the tensioned material helps to keep the particles in place. This allows for more accurate and efficient sorting of particles, resulting in higher quality products.

Finally, urethane tensioned sieves are also more cost-effective than traditional sieves. The tensioned design of the sieves allows them to be produced in larger quantities, resulting in lower production costs. Additionally, the polyurethane material used in the sieves is also more cost-effective than traditional materials, resulting in further cost savings.

Overall, urethane tensioned sieve OEM aggregate and factory vibrating polyurethane fine plate can improve your production process by providing superior durability, efficiency, and cost-effectiveness. This makes them an ideal choice for any industrial production process.

The Benefits of Using Urethane Tensioned Sieve OEM Aggregate and Factory Vibrating Polyurethane Fine Plate in Your Manufacturing Facility