Exploring Wholesale mesh screen: A Comprehensive Guide to Stone sieving screen Mesh Pricelist and Types of screen mesh sizes

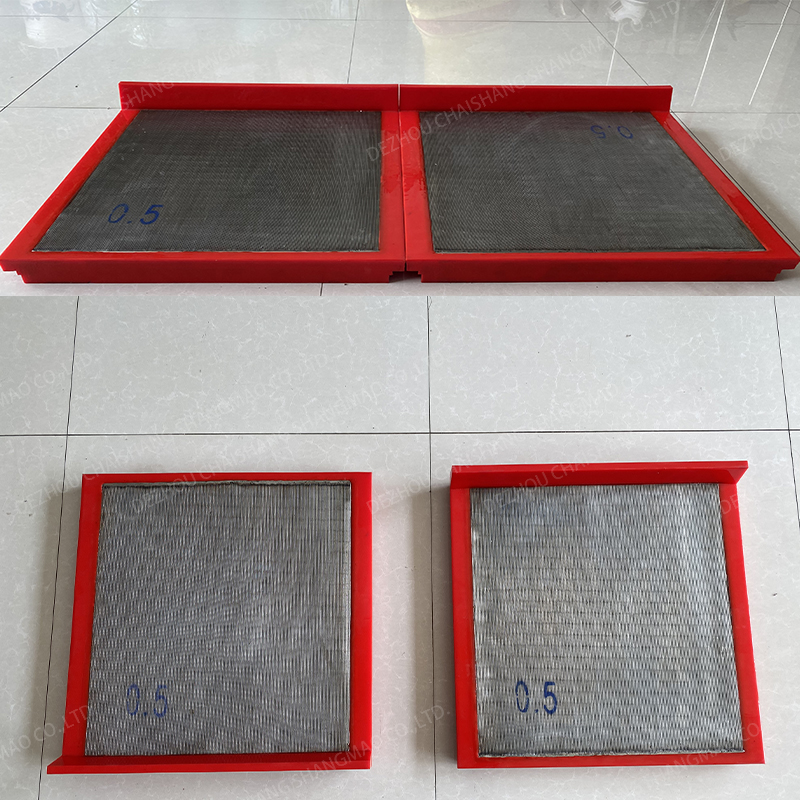

The world of construction and landscaping is vast and complex, with a myriad of tools and materials that are essential for various tasks. One such indispensable tool is the mesh screen, specifically used for stone sieving. This article aims to provide a comprehensive guide to wholesale mesh screen, stone sieving screen mesh pricelist, and the different types of screen mesh sizes available in the market. Mesh screens are primarily used in construction and landscaping projects to sieve and sort stones according to their sizes. They are made from a variety of materials, including stainless steel, galvanized steel, and plastic, each offering unique benefits. Stainless steel mesh screens, for instance, are known for their durability and resistance to rust, making them ideal for long-term outdoor use. Galvanized steel mesh screens, on the other hand, are coated with a layer of zinc to prevent corrosion, making them a cost-effective choice for projects with a tight budget. Plastic mesh screens are lightweight and easy to handle, making them suitable for small-scale, DIY projects. When it comes to purchasing mesh screens, buying in bulk or wholesale can be a cost-effective option. Wholesale mesh screen suppliers often offer significant discounts for large orders, making it an attractive option for construction companies and landscaping businesses that require large quantities of mesh screens for their projects. However, the pricelist for stone sieving screen mesh can vary widely depending on several factors, including the material of the mesh screen, the size of the order, and the supplier’s pricing policy. Therefore, it is crucial to do thorough research and compare prices from different suppliers before making a purchase.In addition to the material and price, another critical factor to consider when purchasing mesh screens is the size. The size of a mesh screen is determined by the number of openings per linear inch, also known as the mesh count. The higher the mesh count, the smaller the openings, and vice versa. For stone sieving, mesh screens with a lower mesh count are typically used to allow larger stones to be separated from smaller ones. Common mesh sizes for stone sieving range from 4 mesh (with 4 openings per inch) to 100 mesh (with 100 openings per inch). However, custom sizes can also be ordered to meet specific project requirements. Understanding the different types of screen mesh sizes is crucial as it directly impacts the efficiency and effectiveness of the stone sieving process. Using a mesh screen with the wrong size can result in inaccurate sorting of stones, leading to potential issues in the construction or landscaping project. Therefore, it is essential to choose the right mesh size based on the size of the stones to be sieved and the desired level of precision.

In conclusion, mesh screens play a vital role in construction and landscaping projects, particularly in stone sieving. When purchasing mesh screens, it is important to consider factors such as the material, price, and size. Buying in wholesale can be a cost-effective option, but it requires careful research and comparison of prices from different suppliers. Furthermore, understanding the different types of screen mesh sizes is crucial to ensure the efficiency and accuracy of the stone sieving process.