The Benefits of High Quality high frequency polyurethane.

screen mining: How It Can Improve Your Sand Sieving Process. High frequency polyurethane screen mining is a process that involves the use of a vibrating screen to separate particles of different sizes. This process is used in a variety of industries, including mining, construction, and manufacturing. In this blog post, we will discuss the benefits of using high quality high frequency polyurethane screen mining for sand sieving. We will also discuss how this process can improve your sand sieving process and help you achieve better results

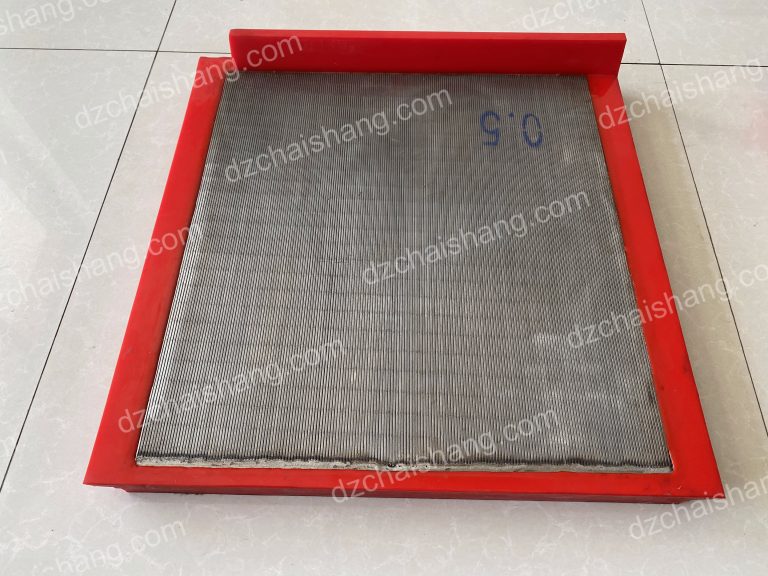

Introduction to polyurethane screen plate

Polyurethane screen plate is a mesh product produced with polyurethane as raw material. The hole shapes of the sieve plate are slits, rectangles, circles, and squares. The main application industries are coal washing plants, coking plants, mines, power plants, dredging companies, metallurgy, petroleum, petrochemical and other enterprises. The main application equipment is the vibrating screen.

Characteristics of polyurethane screen plate

- It has good wear resistance and long service life. Its wear resistance is 3 to 5 times that of steel screen plates and more than 5 times that of ordinary rubber screen plates.

- The maintenance workload is small, the polyurethane screen plate is not easy to be damaged and has a long service life, so the maintenance workload and loss of production shutdown can be greatly reduced.

- The total cost is low. Although the one-time investment of polyurethane screen plates of the same specification (area) is higher (about 2 times) than that of stainless steel screen plates, the service life of polyurethane screen plates is 3 to 5 times that of stainless steel screen plates, and maintenance and replacement are The number of times is small, so the total cost is not high and it is economically very cost-effective.

- It has good moisture resistance and can work with water as the medium. In the case of water, oil and other media, the friction coefficient between polyurethane and materials is reduced, which is more conducive to screen penetration, improves screening efficiency, and can avoid wet particles. At the same time, due to the reduced friction coefficient, the wear is reduced and the service life is improved.

- Corrosion-resistant, non-flammable, non-toxic and tasteless.

- Due to the reasonable design of the screen holes and the unique manufacturing process of the sieve plate, particles of extreme size will not block the screen holes.

- It has good vibration absorption performance and strong silencing ability, which can reduce noise and make the objects on the screen less likely to break during the vibration process.

- Due to the characteristics of secondary vibration of polyurethane, the polyurethane screen plate has a self-cleaning effect, so the screening efficiency is high.

- Save energy and reduce consumption. Polyurethane has a small specific gravity and is much lighter than a steel screen of the same size, thus reducing the load on the screen machine, saving power consumption, and extending the life of the screen machine.

Polyurethane screen plate structure

Skeleton screen plate, strip hole screen plate, tensioning screen plate, slit screen plate, square hole screen, large hole screen, small hole screen, polyurethane rope woven screen, slit screen.

- Board:

Traffic warning boards, stamping-resistant boards, scrapers, wear-resistant boards, rubber-coated boards, automobile linings, mechanical pads, wear-resistant scrapers, sandblasting machine guards, road roller scrapers, wear-resistant sheets.

- Accessories:

Mud pump piston, impeller, vehicle bushing, sheath, buffer block, slide wheel, steel cable casing, printing ink barrier, polyurethane rod, polyurethane spring, polyurethane pad, polyurethane mold, rubber roller, sweeper wheel , polyurethane wheels, polyurethane rubber, plum blossom pads, polyurethane ropes, seals, rollers, mixing scrapers, cyclones.