Benefits of Using Good Quality Vibrating polyurethane Trommel Deck

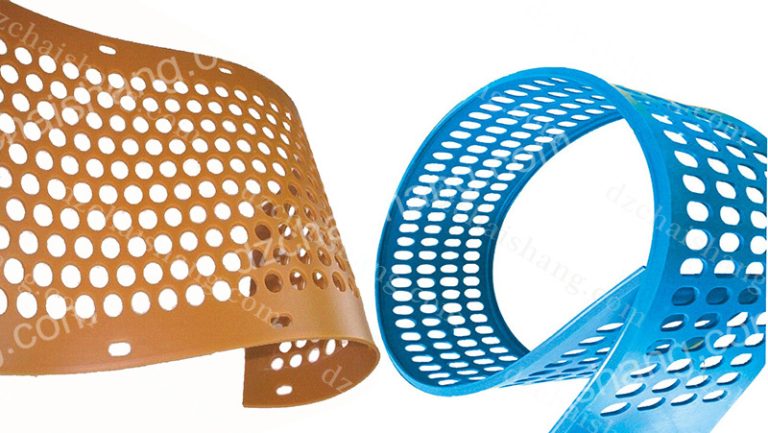

Polyurethane trommel decks are an essential component in the screening process for many industries, including mining, construction, and recycling. These decks are designed to efficiently separate materials by size, allowing for the extraction of valuable resources and the removal of unwanted debris. When it comes to choosing a trommel deck, quality is key. Investing in a good quality vibrating polyurethane trommel deck can offer a range of benefits that can improve the efficiency and effectiveness of your screening operations.

One of the primary benefits of using a good quality vibrating polyurethane trommel deck is its durability. Polyurethane is a highly durable material that is resistant to wear and tear, making it ideal for use in high-impact screening applications. A high-quality polyurethane trommel deck can withstand the rigors of continuous use without experiencing premature wear or damage, ensuring that your screening operations remain efficient and effective over the long term.

In addition to its durability, a good quality vibrating polyurethane trommel deck also offers superior screening performance. The flexibility and elasticity of polyurethane allow the deck to effectively screen a wide range of materials, from fine particles to larger aggregates, with precision and accuracy. This results in a higher quality end product and increased productivity, as the deck can efficiently separate materials of different sizes without clogging or blinding.

Furthermore, a good quality vibrating polyurethane trommel deck is designed to enhance the overall screening process. The vibrating action of the deck helps to agitate the material being screened, ensuring that it is evenly distributed across the surface of the deck for optimal screening efficiency. This helps to prevent material buildup and ensures that the deck remains clear and free-flowing, reducing downtime and maintenance requirements.

Another key benefit of using a good quality vibrating polyurethane trommel deck is its versatility. These decks can be customized to meet the specific needs of your screening application, with options for different aperture sizes, panel thicknesses, and deck designs. This flexibility allows you to tailor the deck to the unique requirements of your operation, ensuring that you achieve the best possible screening results.

In conclusion, investing in a good quality vibrating polyurethane trommel deck can offer a range of benefits that can improve the efficiency and effectiveness of your screening operations. From its durability and superior screening performance to its ability to enhance the overall screening process and its versatility, a high-quality polyurethane deck is a valuable asset for any industry that relies on efficient material separation. By choosing a good quality vibrating polyurethane trommel deck, you can ensure that your screening operations run smoothly and effectively, leading to increased productivity and profitability in the long run.

How to Choose the Best Good Quality Vibrating Polyurethane Trommel Deck for Your Needs

When it comes to choosing the best vibrating polyurethane trommel deck for your needs, quality is key. A good quality deck will not only last longer but also provide better performance and efficiency. With so many options available on the market, it can be overwhelming to make the right choice. In this article, we will discuss the factors to consider when selecting a good quality vibrating polyurethane trommel deck.

First and foremost, it is important to consider the material of the deck. Polyurethane is a popular choice for trommel decks due to its durability and resistance to abrasion. A good quality polyurethane deck should be made from high-grade materials that can withstand the wear and tear of constant use. Look for decks that are reinforced with additional layers or coatings to ensure longevity.

Another important factor to consider is the design of the deck. A good quality vibrating polyurethane trommel deck should have a well-thought-out design that maximizes screening efficiency. Look for decks that have a high open area to allow for maximum throughput and screening capacity. Additionally, consider the size and shape of the apertures on the deck, as this will impact the size of the particles that can pass through.

In addition to material and design, it is important to consider the overall construction of the deck. A good quality vibrating polyurethane trommel deck should be sturdy and well-built to withstand the rigors of heavy-duty screening applications. Look for decks that are welded or bolted together securely to prevent any weak points or potential failures.

Furthermore, consider the maintenance requirements of the deck. A good quality vibrating polyurethane trommel deck should be easy to clean and maintain to ensure optimal performance. Look for decks that are resistant to clogging and buildup, as this can affect screening efficiency. Additionally, consider decks that are easy to access for inspection and maintenance purposes.

When choosing a vibrating polyurethane trommel deck, it is also important to consider the reputation of the manufacturer. Look for decks that are made by reputable companies with a track record of producing high-quality products. Consider reading reviews and testimonials from other customers to gauge the performance and reliability of the deck.

In conclusion, choosing a good quality vibrating polyurethane trommel deck requires careful consideration of material, design, construction, maintenance, and manufacturer reputation. By taking the time to research and evaluate your options, you can ensure that you select a deck that meets your screening needs and provides long-lasting performance. Remember to prioritize quality over price when making your decision, as investing in a good quality deck will ultimately save you time and money in the long run.