了解聚氨酯精細板在採礦作業中的重要性

聚氨酯甲板應用中採用的直接張緊繫統進一步提高了其性能和使用壽命。透過消除對螺栓或夾子等傳統緊固方法的需求,該系統最大限度地減少了應力集中和潛在的故障點。因此,聚氨酯甲板可以承受更高的負載並以更高的速度運行,而不會影響完整性,從而最大限度地延長正常運行時間和生產率。環境因素。與鋼等傳統材料相比,聚氨酯具有卓越的耐腐蝕性,降低了生鏽或腐蝕產物污染的風險。此外,聚氨酯無毒且惰性,在其整個生命週期中對環境的影響極小。 This aligns with the growing emphasis on sustainable practices within the mining industry, further underscoring the relevance of urethane fine plates in modern mining operations.

In conclusion, urethane fine plates play a vital role in enhancing the efficiency, reliability, and sustainability of mining營運.其卓越的耐用性、多功能性和性能使其成為篩選、分選和分類過程中不可或缺的組件。隨著採礦業的不斷發展,對聚氨酯精細板等創新解決方案的需求預計將上升,從而推動該領域的進一步進步和應用。

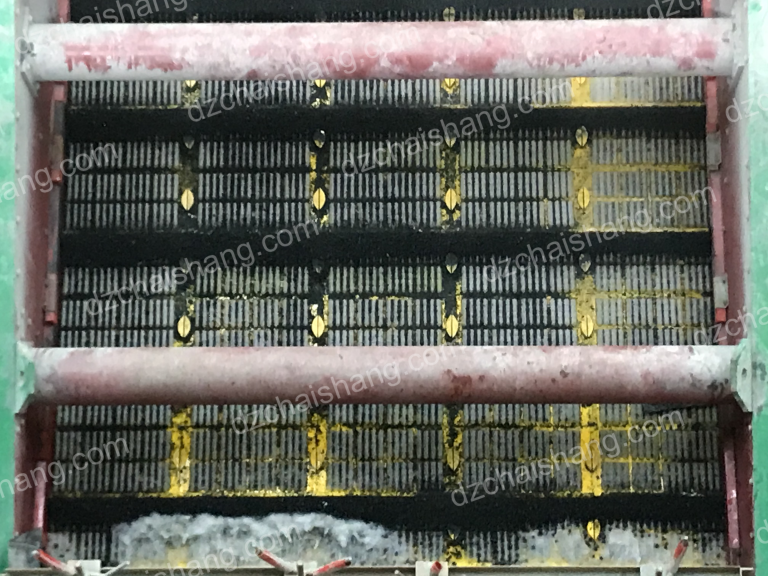

One of the primary applications of urethane fine plates in mining is in screening operations. These plates are commonly used in vibrating screens, where they serve as the screening surface. Their high abrasion resistance enables them to withstand the constant friction and impact from the materials being processed, thereby maintaining screening efficiency over extended periods. Additionally, their flexibility allows them to conform to the contours of the screen deck, ensuring optimal contact and screening performance.

Beyond screening, urethane fine plates also find utility in sorting and classification processes within mining operations. Whether separating ores based on size, density, or other characteristics, these plates offer precise and reliable performance. Their smooth surface minimizes material adhesion and blinding, preventing clogging and ensuring uninterrupted operation. This is particularly critical in high-throughput applications where efficiency is paramount.

In addition to their mechanical properties, urethane fine plates offer advantages in terms of customization and versatility. Manufacturers can tailor the plates to meet specific size, shape, and aperture requirements, allowing for seamless integration into diverse mining equipment and processes. Furthermore, advancements in urethane formulation have led to the development of specialty plates with enhanced properties such as increased abrasion resistance or improved flexibility, catering to the evolving needs of the mining industry.

The direct tensioning system employed in urethane deck applications further enhances their performance and longevity. By eliminating the need for traditional fastening methods such as bolts or clips, this system minimizes stress concentrations and potential points of failure. As a result, urethane decks can withstand higher loads and operate at elevated speeds without compromising integrity, thereby maximizing uptime and productivity.

The benefits of urethane fine plates extend beyond operational efficiency to encompass environmental considerations as well. Compared to traditional materials such as steel, urethane offers superior corrosion resistance, reducing the risk of contamination from rust or corrosion products. Additionally, urethane is non-toxic and inert, posing minimal environmental impact throughout its lifecycle. This aligns with the growing emphasis on sustainable practices within the mining industry, further underscoring the relevance of urethane fine plates in modern mining operations.

In conclusion, urethane fine plates play a vital role in enhancing the efficiency, reliability, and sustainability of mining operations. Their exceptional durability, versatility, and performance make them indispensable components in screening, sorting, and classification processes. As the mining industry continues to evolve, the demand for innovative solutions like urethane fine plates is expected to rise, driving further advancements and applications in the field.