使用聚氨酯張緊篩進行脫水應用的好處

如何正確維護和清潔聚氨酯張緊篩以獲得最佳性能

聚氨酯張緊篩是許多產業(包括採礦、骨材和回收)脫水過程中的關鍵組成部分。這些篩子在從液體中分離固體方面發揮著至關重要的作用,確保最終產品符合品質標準。為了保持聚氨酯張緊篩的最佳性能並延長其使用壽命,適當的維護和清潔至關重要。檢查篩子是否有磨損、撕裂或孔洞對於防止任何可能影響其性能的潛在問題至關重要。建議每次使用前後檢查篩子,以確保其狀況良好。隨著時間的推移,碎片、污垢和其他污染物會積聚在篩子上,影響其效率。要清潔篩子,請先將它們從脫水設備中取出並用水沖洗以去除任何鬆散的顆粒。對於更頑固的污垢和碎片,可以使用溫和的清潔劑輕輕擦洗篩子。這將防止任何水分被困在篩子中,從而導致黴菌生長。篩子乾燥後,再次檢查以確保它們清潔且沒有任何殘留的碎片。將篩子存放在清潔、乾燥的環境中將有助於防止損壞並延長其使用壽命。建議將篩子存放在陰涼、乾燥的地方,避免陽光直射和極端溫度。修理或更換損壞的聚氨酯張緊篩將有助於保持最佳性能並防止任何可能影響脫水過程的問題。 。定期檢查、清潔和適當的儲存將有助於確保篩子繼續有效且有效率地運作。遵循這些維護技巧,您可以延長聚氨酯張緊篩的使用壽命,並確保它們繼續滿足脫水過程的要求。

How to Properly Maintain and Clean polyurethane Tensioned Sieves for Optimal Performance

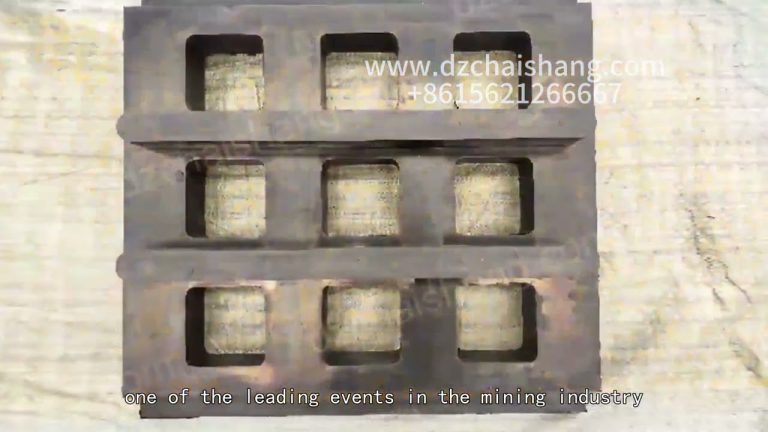

Polyurethane tensioned sieves are a crucial component in the dewatering process for many industries, including mining, aggregate, and recycling. These sieves play a vital role in separating solids from liquids, ensuring that the final product meets quality standards. To maintain optimal performance and prolong the lifespan of your polyurethane tensioned sieves, proper maintenance and cleaning are essential.

One of the most important aspects of maintaining polyurethane tensioned sieves is regular inspection. Inspecting the sieves for wear and tear, tears, or holes is crucial to prevent any potential issues that could affect their performance. It is recommended to inspect the sieves before and after each use to ensure they are in good condition.

In addition to regular inspections, cleaning the polyurethane tensioned sieves is also essential. Over time, debris, dirt, and other contaminants can build up on the sieves, affecting their efficiency. To clean the sieves, start by removing them from the dewatering equipment and rinsing them with water to remove any loose particles. For more stubborn dirt and debris, a mild detergent can be used to gently scrub the sieves.

After cleaning the sieves, it is important to allow them to dry completely before reinstalling them. This will prevent any moisture from getting trapped in the sieves, which could lead to mold or mildew growth. Once the sieves are dry, inspect them again to ensure they are clean and free of any remaining debris.

In addition to regular maintenance and cleaning, proper storage of polyurethane tensioned sieves is also crucial. Storing the sieves in a clean, dry environment will help prevent damage and prolong their lifespan. It is recommended to store the sieves in a cool, dry place away from direct sunlight and extreme temperatures.

If any damage or wear is detected during the inspection process, it is important to address it promptly. Repairing or replacing damaged polyurethane tensioned sieves will help maintain optimal performance and prevent any issues that could affect the dewatering process.

In conclusion, proper maintenance and cleaning of polyurethane tensioned sieves are essential for optimal performance and longevity. Regular inspections, cleaning, and proper storage will help ensure that the sieves continue to function effectively and efficiently. By following these maintenance tips, you can prolong the lifespan of your polyurethane tensioned sieves and ensure they continue to meet the demands of your dewatering process.