用於採礦應用中振動篩的聚氨酯篩網的優點

優化性能:UGOL ROSSII 和採礦中使用的聚氨酯絲篩網的維護技巧

此外,正確的安裝對於最大限度地發揮聚氨酯絲網的性能至關重要。確保篩網安裝正確、牢固,可以防止過早磨損或錯位等問題,這些問題可能會影響篩選精度。遵循製造商指南並聘請經驗豐富的專業人員進行安裝可以幫助避免常見陷阱並從一開始就確保最佳性能。聚氨酯絲篩網依靠適當的張力來保持其形狀和有效性。定期檢查和調整張力可確保篩網保持拉緊並能承受篩選過程的嚴酷考驗。未能保持足夠的張力可能會導致篩網下垂或拉伸,從而導致效率降低和潛在損壞。暴露在惡劣的天氣條件、磨蝕性材料和過度振動中會加速磨損和惡化。採取保護塗層或覆蓋物等措施可以幫助屏蔽篩網免受這些因素的影響,延長其使用壽命並優化性能。透過追蹤吞吐量、粒度分佈和篩選效率等關鍵指標,操作員可以及早發現潛在問題並根據需要採取糾正措施。這種主動方法可最大程度地減少對生產的干擾並確保一致的篩分性能。透過實施包括定期清潔、檢查和預防措施在內的全面維護策略,操作員可以延長篩子的使用壽命並最大限度地提高篩分效率。此外,保持主動並監控效能指標可以及早發現問題並及時幹預,以最大限度地減少停機時間。透過適當的保養和維護,聚氨酯絲篩網可以在要求嚴格的篩分應用中繼續提供可靠的性能。

Optimizing Performance: Maintenance Tips for polyurethane wire screens Used in UGOL ROSSII & mining

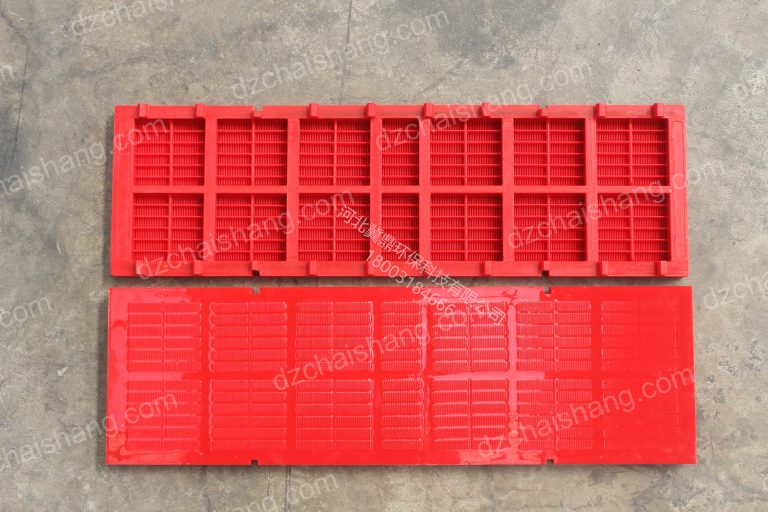

Polyurethane wire screens play a crucial role in optimizing the performance of vibrating screens, particularly in industries like mining where efficiency and durability are paramount. These screens are integral components in UGOL ROSSII & MINING operations, facilitating the separation of materials of varying sizes. To ensure that polyurethane wire screens continue to deliver optimal performance, proper maintenance is essential.

One of the primary maintenance tips for polyurethane wire screens is regular cleaning. Over time, these screens can accumulate debris, dust, and other particles, which can affect their efficiency. Routine cleaning helps to prevent material buildup and ensures consistent screening performance. Additionally, inspecting the screens for any signs of damage or wear is crucial. Even minor tears or abrasions can compromise the effectiveness of the screen and lead to inefficiencies in the screening process.

Incorporating a preventive maintenance schedule is essential for prolonging the lifespan of polyurethane wire screens. This includes regular inspections, cleaning, and addressing any issues promptly to prevent further damage. By staying proactive, operators can minimize downtime and maintain optimal screening efficiency.

Furthermore, proper installation is critical for maximizing the performance of polyurethane wire screens. Ensuring that the screens are installed correctly and securely prevents issues such as premature wear or misalignment, which can affect screening accuracy. Following manufacturer guidelines and utilizing experienced professionals for installation can help avoid common pitfalls and ensure optimal performance from the outset.

Another important aspect of maintenance is monitoring screen tension. Polyurethane wire screens rely on proper tension to maintain their shape and effectiveness. Regularly checking and adjusting the tension ensures that the screens remain taut and can withstand the rigors of the screening process. Failure to maintain adequate tension can result in sagging or stretching of the screen, leading to decreased efficiency and potential damage.

In addition to mechanical maintenance, it is essential to consider environmental factors that can impact polyurethane wire screens. Exposure to harsh weather conditions, abrasive materials, and excessive vibration can accelerate wear and deterioration. Implementing measures such as protective coatings or covers can help shield the screens from these elements, prolonging their lifespan and optimizing performance.

Regularly monitoring the performance of polyurethane wire screens is crucial for identifying any issues promptly. By tracking key metrics such as throughput, particle size distribution, and screen efficiency, operators can identify potential problems early on and take corrective action as needed. This proactive approach minimizes disruptions to production and ensures consistent screening performance.

In conclusion, proper maintenance is essential for optimizing the performance of polyurethane wire screens used in UGOL ROSSII & MINING operations. By implementing a comprehensive maintenance strategy that includes regular cleaning, inspection, and preventive measures, operators can prolong the lifespan of the screens and maximize screening efficiency. Additionally, staying proactive and monitoring performance metrics allows for early detection of issues and timely intervention to minimize downtime. With proper care and maintenance, polyurethane wire screens can continue to deliver reliable performance in demanding screening applications.