了解基礎:聚氨酯篩板綜合指南

維持並最大化聚氨酯篩板效率的重要技巧

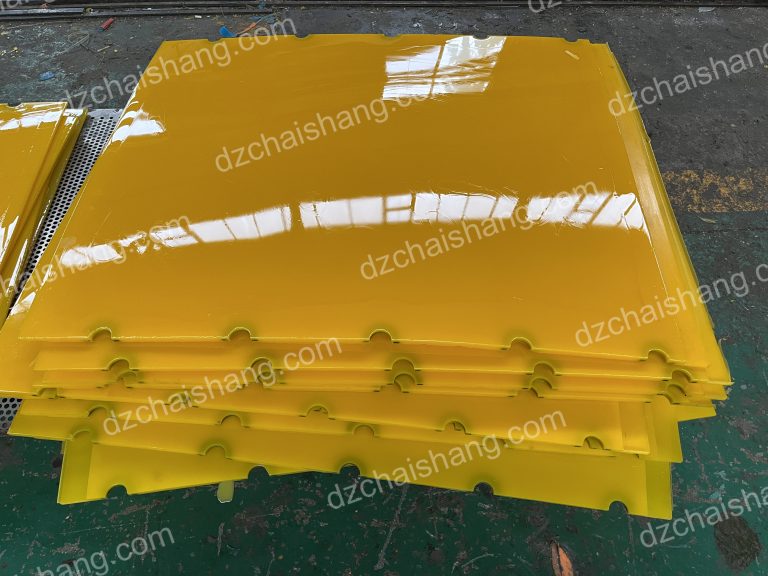

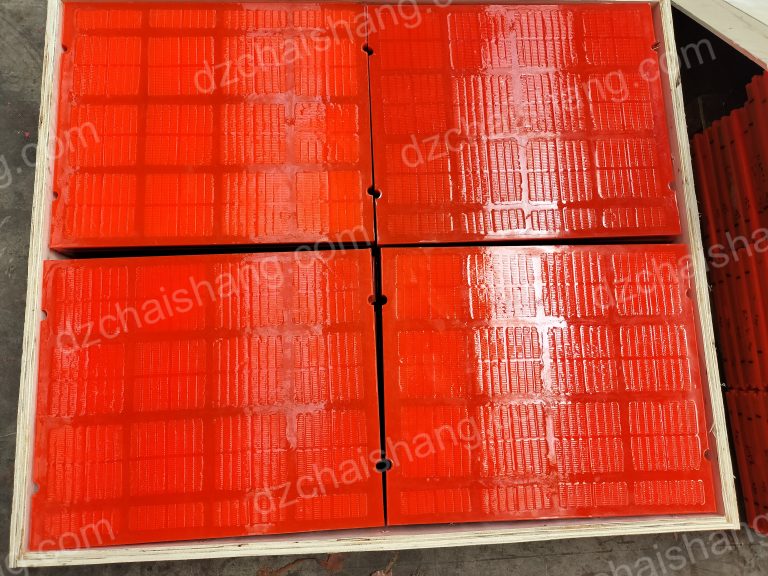

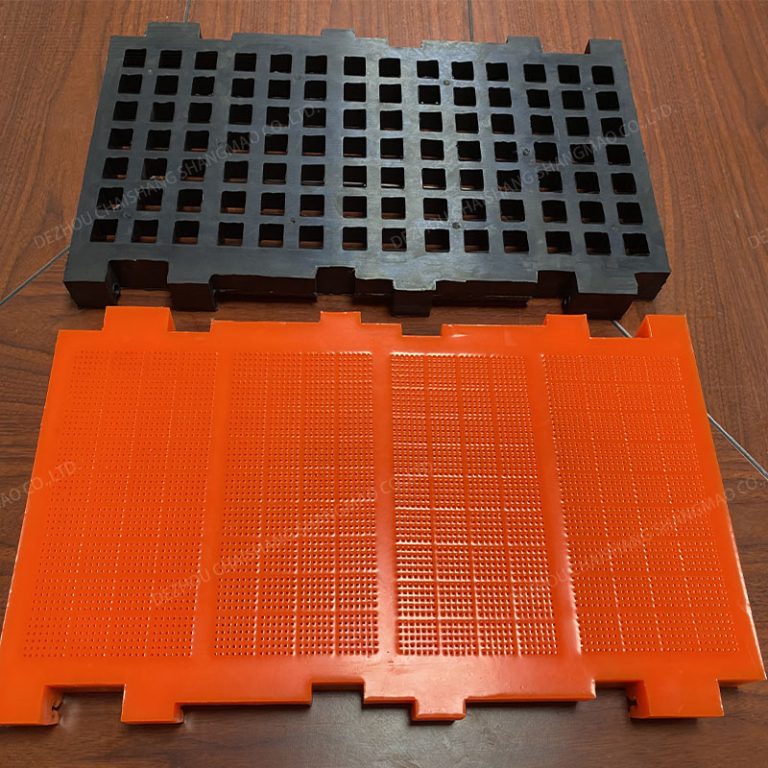

聚氨酯篩板是許多工業製程的重要組成部分,特別是在採礦和集料作業中。這些面板以其耐用性、靈活性和承受惡劣條件的能力而聞名。然而,為了確保其使用壽命並保持最佳性能,必須遵循某些維護和效率最大化準則。 。例如,篩選磨料會導致面板磨損得更快。因此,建議選擇硬度等級適合特定應用的面板。這不僅可以提高面板的耐用性,還可以提高其效率。隨著時間的推移,由於持續暴露在重負載和磨料中,面板可能會出現裂縫、撕裂或孔洞。這些缺陷會顯著降低篩選效率並導致有價值材料的損失。因此,建議定期檢查面板並及時更換損壞的面板。隨著時間的推移,細顆粒會積聚在篩孔中,降低篩分效率。定期清潔有助於去除這些顆粒並保持面板的最佳性能。然而,重要的是要使用非研磨性清潔方法以避免損壞面板。面板安裝不正確可能會導致各種問題,包括篩選效率降低、過早磨損,甚至面板故障。因此,嚴格遵循製造商的安裝指南至關重要。這包括確保面板牢固固定並有足夠的張力以防止下垂。例如,在過高或過低的溫度下操作面板可能會導致它們更快地降解。同樣,將面板暴露在腐蝕性物質中也會縮短其使用壽命。因此,建議在製造商建議的溫度範圍內操作面板,並避免將其暴露於腐蝕性物質中。例如,具有較大孔徑的面板可以處理較大體積的材料,但它們在篩選較小顆粒時可能不那麼有效。另一方面,孔徑較小的面板可以更有效地篩選較小的顆粒,但它們可能無法處理較大體積的材料。因此,選擇適合特定應用的面板設計非常重要。透過遵循這些指南,使用者可以確保他們的聚氨酯篩板具有最佳的性能和使用壽命。

When it comes to maintenance, polyurethane screen panels require minimal upkeep. Their robust nature means they can withstand harsh conditions without significant damage. However, regular inspections are recommended to identify any signs of wear or damage early. If a panel is damaged, it should be replaced immediately to prevent further issues.

Despite their durability, polyurethane screen panels are not indestructible. They can be damaged by excessive loads or sharp objects, which can cause tears or holes in the panel. Therefore, it’s essential to monitor the load on the screen and ensure that the material being screened does not contain any sharp or oversized particles.

In terms of cost, polyurethane screen panels may initially seem more expensive than other types of screen panels, such as those made from wire mesh or rubber. However, when considering the panels’ lifespan and the reduced maintenance costs, polyurethane screen panels often prove to be a more cost-effective solution in the long run.

In conclusion, polyurethane screen panels offer numerous benefits, including high durability, efficiency, and versatility. They are easy to install and require minimal maintenance, making them a practical choice for various industries. However, it’s important to use these panels correctly and conduct regular inspections to ensure their optimal performance. By understanding the basics of polyurethane screen panels, professionals can make informed decisions and maximize the benefits of these essential components.

Top Tips for Maintaining and Maximizing the Efficiency of Polyurethane Screen Panels

Polyurethane screen panels are a crucial component in many industrial processes, particularly in mining and aggregate operations. These panels are renowned for their durability, flexibility, and ability to withstand harsh conditions. However, to ensure their longevity and maintain optimal performance, it is essential to follow certain maintenance and efficiency-maximizing guidelines.

Firstly, it is important to understand that the lifespan of polyurethane screen panels is largely dependent on the type of material they are screening. For instance, screening abrasive materials can cause the panels to wear out faster. Therefore, it is advisable to select a panel with a hardness level suitable for the specific application. This will not only enhance the panel’s durability but also its efficiency.

Regular inspection of the polyurethane screen panels is another crucial maintenance tip. Over time, the panels may develop cracks, tears, or holes due to constant exposure to heavy loads and abrasive materials. These defects can significantly reduce the screening efficiency and lead to the loss of valuable materials. Therefore, it is recommended to inspect the panels regularly and replace any damaged ones promptly.

In addition to regular inspections, it is also important to clean the polyurethane screen panels regularly. Over time, fine particles can accumulate in the screen apertures, reducing the screening efficiency. Regular cleaning helps to remove these particles and maintain the panel’s optimal performance. However, it is important to use non-abrasive cleaning methods to avoid damaging the panels.

Another tip for maximizing the efficiency of polyurethane screen panels is to ensure proper installation. Incorrectly installed panels can lead to a variety of problems, including reduced screening efficiency, premature wear, and even panel failure. Therefore, it is crucial to follow the manufacturer’s installation guidelines closely. This includes ensuring that the panels are securely fastened and that there is adequate tension to prevent sagging.

The operating conditions can also significantly impact the efficiency and lifespan of polyurethane screen panels. For instance, operating the panels at excessively high or low temperatures can cause them to degrade faster. Similarly, exposing the panels to corrosive substances can also reduce their lifespan. Therefore, it is advisable to operate the panels within the manufacturer’s recommended temperature range and avoid exposing them to corrosive substances.

Lastly, it is important to consider the panel’s design when trying to maximize its efficiency. For instance, panels with larger apertures can handle larger volumes of material, but they may not be as effective at screening smaller particles. On the other hand, panels with smaller apertures can screen smaller particles more effectively, but they may not be able to handle larger volumes of material. Therefore, it is important to select a panel design that is suitable for the specific application.

In conclusion, maintaining and maximizing the efficiency of polyurethane screen panels involves a combination of proper selection, regular inspection and cleaning, correct installation, and operation within the recommended conditions. By following these guidelines, users can ensure that their polyurethane screen panels deliver optimal performance and longevity.