探索聚氨酯篩板生產先進技術

了解聚氨酯篩板的優點與應用

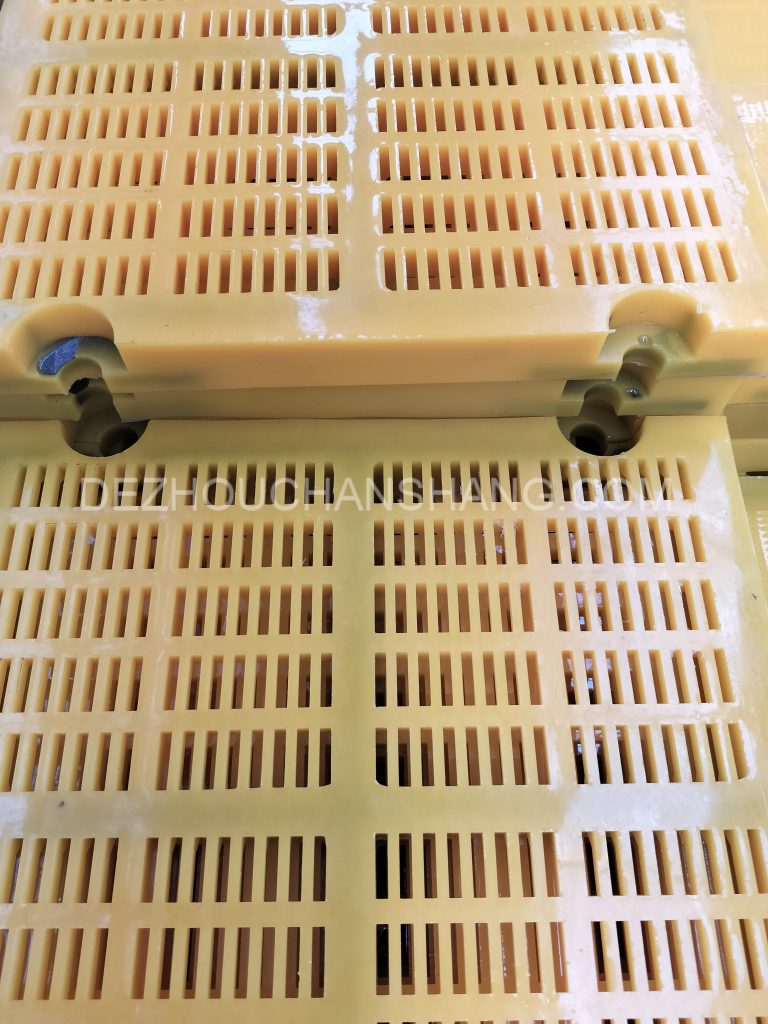

聚氨酯篩板是採礦和骨材產業的重要組成部分,具有多種優點和應用,使其成為這些產業不可或缺的工具。這些面板以其耐用性、效率和多功能性而聞名,使其成為業內許多專業人士的首選。其成為理想的材料適用於惡劣和苛刻的環境。這種耐用性是聚氨酯篩板廣泛應用於採礦和骨材產業的關鍵原因之一。這些行業通常涉及研磨材料的加工,這會快速磨損其他類型的螢幕。然而,聚氨酯篩板可以承受這種磨損,提供持久的解決方案,可以顯著降低維護和更換成本。它們旨在透過根據尺寸有效分離材料來提供最大的篩選效率。這是透過使用各種孔徑形狀和尺寸來實現的,這些孔徑可以客製化以滿足特定的篩選要求。這種高水準的效率可以提高生產力和獲利能力,使聚氨酯篩板成為任何操作中的寶貴資產。它們可用於濕式和乾式篩選應用,使其適用於各種環境。此外,它們可以製造成各種尺寸和配置,從而可以用於各種篩選設備。這種多功能性使聚氨酯篩板成為一種靈活的解決方案,可以滿足採礦和集料行業的多樣化需求。它們還具有環境效益。聚氨酯是一種可回收材料,這意味著舊的或損壞的篩板可以回收成新產品。這不僅減少了浪費,也有助於產業的永續發展。在採礦業中,它們用於篩選和分離不同類型的礦物和礦石。在骨料行業中,它們用於對不同尺寸的沙子、礫石和碎石進行分類和分離。它們也用於回收業來分離不同類型的可回收材料。它們的耐用性、效率、多功能性和環境效益使其成為這些領域許多專業人士的最佳選擇。無論是在礦場中篩選礦物,或是在集料廠中分離沙子,聚氨酯篩板都能提供可靠、高效的解決方案,滿足這些產業的多樣化需求。

Once the mold is ready, the polyurethane is heated until it reaches a liquid state. This liquid polyurethane is then poured into the mold and allowed to cool. As it cools, the polyurethane hardens and takes on the shape of the mold. This process, known as casting, allows for the production of screen panels with complex shapes and designs.

After the casting process, the screen panels undergo a curing process. Curing involves exposing the panels to heat for a specific period to enhance their physical properties. This process helps to increase the panel’s hardness and durability, making it more resistant to wear and tear.

The final step in the production process is the finishing stage. This involves trimming any excess material from the panel and smoothing out any rough edges. The panels are then inspected for any defects or inconsistencies. Any panels that do not meet the required standards are rejected and recycled, ensuring that only high-quality products reach the market.

In addition to these standard production techniques, manufacturers are continually exploring new methods to improve the performance and durability of polyurethane screen panels. For instance, some manufacturers are experimenting with the use of additives to enhance the polyurethane’s properties. These additives can improve the panel’s resistance to UV radiation, increase its flexibility, or reduce its weight.

Another area of exploration is the use of advanced manufacturing techniques such as 3D printing. This technology allows for the production of screen panels with intricate designs and precise dimensions. It also enables manufacturers to produce custom panels quickly and efficiently, meeting the unique needs of each customer.

In conclusion, the production of polyurethane screen panels involves a series of advanced techniques that ensure the final product’s high performance and durability. From the selection of high-quality raw materials to the use of precise molds and curing processes, each step is carefully controlled to produce a superior product. As technology continues to evolve, manufacturers are likely to discover even more innovative techniques to enhance the production of these essential components.

Understanding the Benefits and Applications of Polyurethane Screen Panels

Polyurethane screen panels are a crucial component in the mining and aggregate industries, offering a myriad of benefits and applications that make them an indispensable tool in these sectors. These panels are renowned for their durability, efficiency, and versatility, making them a preferred choice for many professionals in the industry.

Polyurethane, a type of polymer, is a material known for its exceptional resistance to wear and tear, making it ideal for use in harsh and demanding environments. This durability is one of the key reasons why polyurethane screen panels are widely used in the mining and aggregate industries. These industries often involve the processing of abrasive materials, which can quickly wear down other types of screens. However, polyurethane screen panels can withstand this wear and tear, providing a long-lasting solution that can significantly reduce maintenance and replacement costs.

In addition to their durability, polyurethane screen panels are also highly efficient. They are designed to provide maximum screening efficiency by effectively separating materials based on size. This is achieved through the use of various aperture shapes and sizes, which can be customized to meet specific screening requirements. This high level of efficiency can lead to increased productivity and profitability, making polyurethane screen panels a valuable asset in any operation.

Versatility is another significant benefit of polyurethane screen panels. They can be used in both wet and dry screening applications, making them suitable for a wide range of environments. Furthermore, they can be manufactured in a variety of sizes and configurations, allowing them to be used in a wide range of screening equipment. This versatility makes polyurethane screen panels a flexible solution that can meet the diverse needs of the mining and aggregate industries.

The benefits of polyurethane screen panels extend beyond their physical properties. They also offer environmental benefits. Polyurethane is a recyclable material, meaning that old or damaged screen panels can be recycled into new products. This not only reduces waste but also contributes to a more sustainable industry.

The applications of polyurethane screen panels are vast and varied. In the mining industry, they are used to screen and separate different types of minerals and ores. In the aggregate industry, they are used to classify and separate different sizes of sand, gravel, and crushed stone. They are also used in the recycling industry to separate different types of recyclable materials.

In conclusion, polyurethane screen panels offer a multitude of benefits and applications that make them an essential tool in the mining and aggregate industries. Their durability, efficiency, versatility, and environmental benefits make them a superior choice for many professionals in these sectors. Whether it’s screening minerals in a mine or separating sand in an aggregate plant, polyurethane screen panels provide a reliable and efficient solution that can meet the diverse needs of these industries.