在鞋類使用人字拖聚氨酯的好處

如何根據您的工業需求客製化礦物聚氨酯篩網

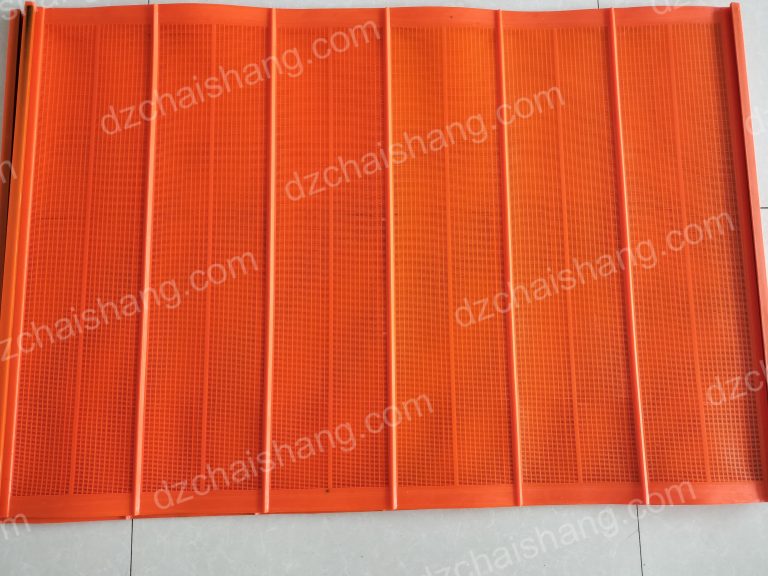

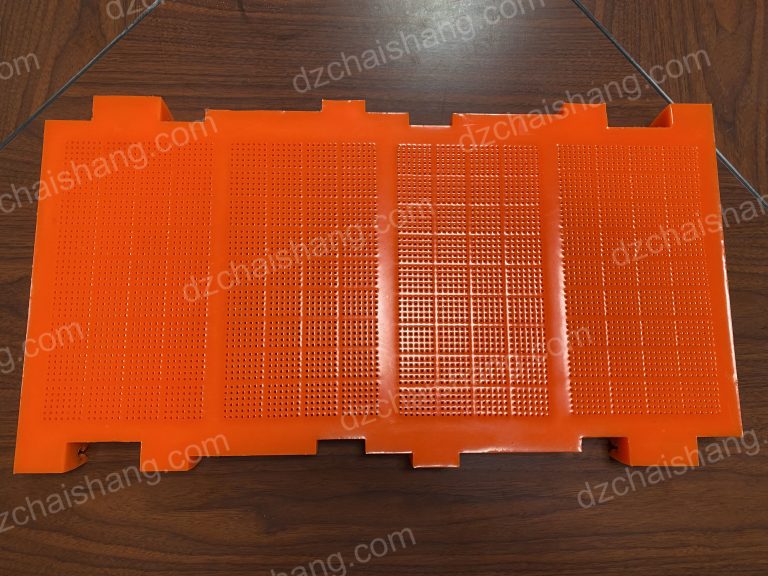

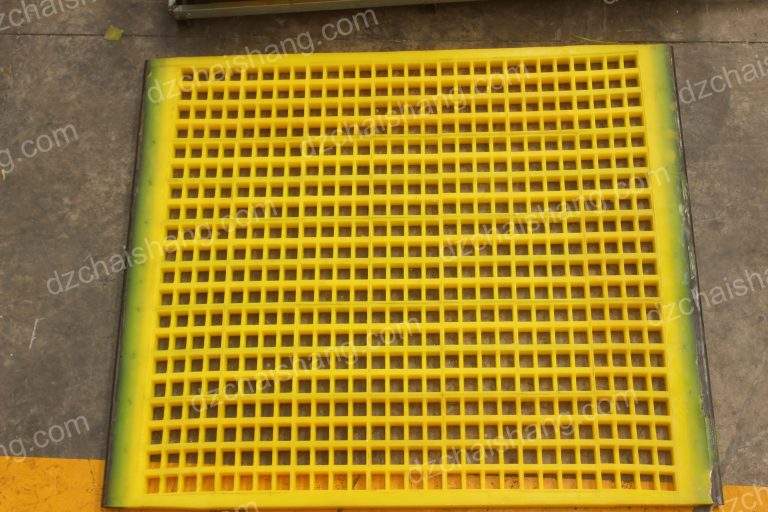

在工業篩選過程中,擁有合適的設備對於確保效率和效果至關重要。許多篩選系統的關鍵組件之一是聚氨酯篩網,它以其耐用性和多功能性而聞名。雖然市面上有許多標準的聚氨酯篩網,但有時需要客製化的礦物聚氨酯篩網來滿足特定的工業需求。此過程的第一步是確定篩選申請的具體要求。這包括考慮諸如被篩分材料的尺寸和形狀、所需的篩分效率以及篩分系統的操作條件等因素。對於礦物聚氨酯篩網,必須特別注意被篩分的礦物類型及其研磨特性。這將有助於確定承受篩分過程磨損所需的聚氨酯材料的硬度和成分。這涉及創建詳細的圖紙和規格,概述螢幕的尺寸、形狀和配置。與熟練的工程師或設計師密切合作非常重要,以確保篩網的設計符合篩分應用的特定要求。這涉及使用專門的設備和技術將聚氨酯材料模製成所需的結構。與具有生產客製化聚氨酯篩網經驗的信譽良好的製造商合作非常重要,以確保最終產品符合最高品質標準。 。這包括將篩網小心地安裝到篩分設備中並進行徹底的性能測試,以確保其滿足所需的篩分效率和有效性。是一個詳細而精確的過程這需要仔細的規劃和執行。透過遵循上述步驟並與經驗豐富的專業人員合作,可以設計和製造滿足任何篩選應用的特定要求的客製化聚氨酯篩網。無論是篩選礦物、骨材或其他材料,客製化的礦物聚氨酯篩網都可以幫助提高工業篩選製程的效率和生產率。

How to Create a Custom-Made Mineral urethane screen for Your Industrial Needs

When it comes to industrial screening processes, having the right equipment is crucial for ensuring efficiency and effectiveness. One key component of many screening systems is the urethane screen, which is known for its durability and versatility. While there are many standard urethane screens available on the market, sometimes a custom-made mineral urethane screen is necessary to meet specific industrial needs.

Creating a custom-made mineral urethane screen involves a detailed process that requires careful planning and precision. The first step in this process is to determine the specific requirements of the screening application. This includes considering factors such as the size and shape of the material being screened, the desired screening efficiency, and the operating conditions of the screening system.

Once the requirements have been established, the next step is to select the appropriate materials for the urethane screen. In the case of a mineral urethane screen, special attention must be paid to the type of minerals being screened and their abrasive properties. This will help determine the hardness and composition of the urethane material needed to withstand the wear and tear of the screening process.

After selecting the materials, the next step is to design the custom-made mineral urethane screen. This involves creating detailed drawings and specifications that outline the dimensions, shape, and configuration of the screen. It is important to work closely with a skilled engineer or designer to ensure that the screen is designed to meet the specific requirements of the screening application.

Once the design is finalized, the next step is to manufacture the custom-made mineral urethane screen. This involves using specialized equipment and techniques to mold and shape the urethane material into the desired configuration. It is important to work with a reputable manufacturer who has experience in producing custom urethane screens to ensure that the final product meets the highest quality standards.

After the custom-made mineral urethane screen has been manufactured, it must be properly installed and tested in the screening system. This involves carefully fitting the screen into the screening equipment and conducting thorough performance tests to ensure that it meets the desired screening efficiency and effectiveness.

In conclusion, creating a custom-made mineral urethane screen for industrial screening applications is a detailed and precise process that requires careful planning and execution. By following the steps outlined above and working with experienced professionals, it is possible to design and manufacture a custom urethane screen that meets the specific requirements of any screening application. Whether screening minerals, aggregates, or other materials, a custom-made mineral urethane screen can help improve efficiency and productivity in industrial screening processes.