在篩選應用中使用聚氨酯篩網的好處

聚氨酯篩網與金屬篩網相比的優缺點

儘管聚氨酯篩網有很多優點,但與金屬篩網相比,它也有一些缺點。主要缺點之一是初始成本較高。聚氨酯螢幕的預購成本可能比傳統金屬螢幕更高,這可能會阻止一些公司進行轉換。然而,重要的是要考慮聚氨酯篩網在降低維護和更換成本方面可以提供的長期成本節約。雖然金屬螢幕可以毫無問題地承受高溫,但聚氨酯螢幕在暴露於極熱時可能會損壞或變形。對於需要在高溫環境下進行篩分的操作(例如鑄造廠或鋼廠)來說,這可能是一個問題。 、提高的篩分效率、並減少了維護要求。雖然它們可能具有較高的初始成本和有限的溫度範圍,但聚氨酯篩網的長期效益使其成為尋求改進篩分製程的採礦和骨材作業的值得投資。透過仔細權衡聚氨酯篩網的優點和缺點,公司可以就是否放棄金屬篩網做出明智的決定。

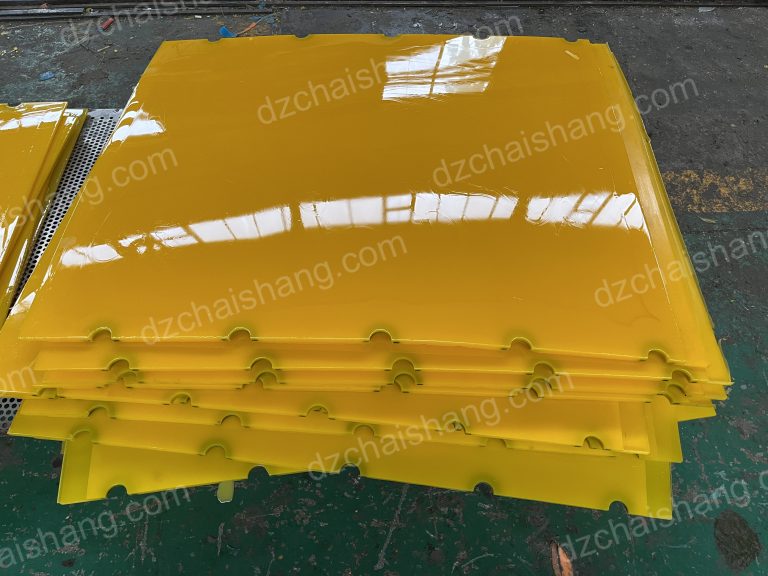

polyurethane screens have become increasingly popular in the mining and aggregate industries due to their numerous advantages over traditional metal screens. These screens are made from a durable and flexible material that offers a number of benefits, including longer wear life, reduced maintenance costs, and improved screening efficiency.

One of the key advantages of polyurethane screens is their superior wear resistance. Unlike metal screens, which can easily become damaged and worn down over time, polyurethane screens are designed to withstand the harsh conditions of mining and aggregate operations. This means that they can last much longer than traditional metal screens, saving companies time and money on replacement costs.

In addition to their durability, polyurethane screens also offer improved screening efficiency. The flexible nature of polyurethane allows for greater vibration during the screening process, which helps to prevent blinding and pegging. This results in a more efficient screening process and higher throughput rates, ultimately leading to increased productivity for mining and aggregate operations.

Another advantage of polyurethane screens is their reduced maintenance requirements. Metal screens often require frequent maintenance and repairs to keep them functioning properly, whereas polyurethane screens are much easier to maintain. They are resistant to corrosion and abrasion, meaning that they do not need to be replaced as often as metal screens. This can help to reduce downtime and increase overall efficiency for mining and aggregate operations.

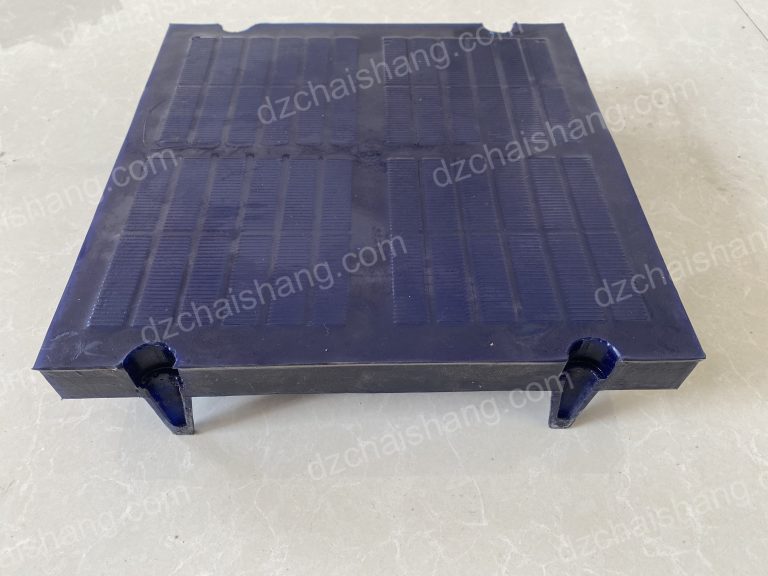

Despite their many advantages, polyurethane screens do have some drawbacks compared to metal screens. One of the main disadvantages is their higher initial cost. Polyurethane screens can be more expensive to purchase upfront than traditional metal screens, which may deter some companies from making the switch. However, it is important to consider the long-term cost savings that polyurethane screens can provide in terms of reduced maintenance and replacement costs.

Another potential drawback of polyurethane screens is their limited temperature range. While metal screens can withstand high temperatures without issue, polyurethane screens may become damaged or deformed when exposed to extreme heat. This can be a concern for operations that require screening in high-temperature environments, such as in foundries or steel mills.

In conclusion, polyurethane screens offer a number of advantages over traditional metal screens, including superior wear resistance, improved screening efficiency, and reduced maintenance requirements. While they may have a higher initial cost and limited temperature range, the long-term benefits of polyurethane screens make them a worthwhile investment for mining and aggregate operations looking to improve their screening processes. By carefully weighing the advantages and disadvantages of polyurethane screens, companies can make an informed decision about whether or not to make the switch from metal screens.