探索聚氨酯板的優點與應用

了解PU振動篩網在工業製程的功能與用途

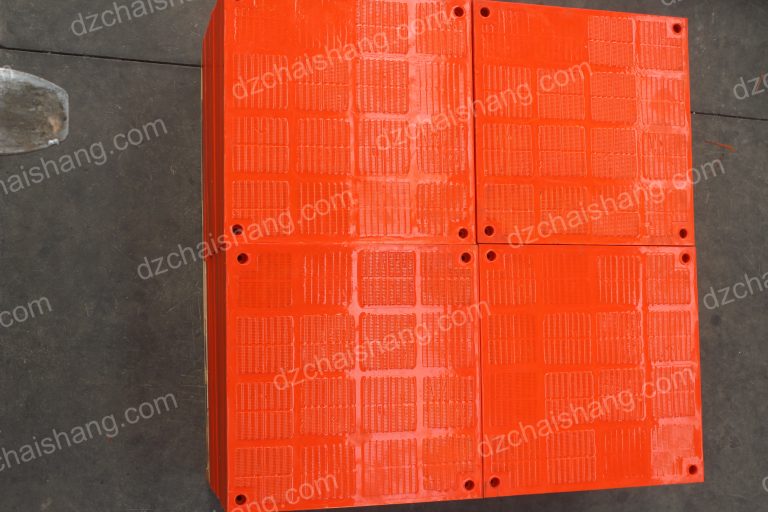

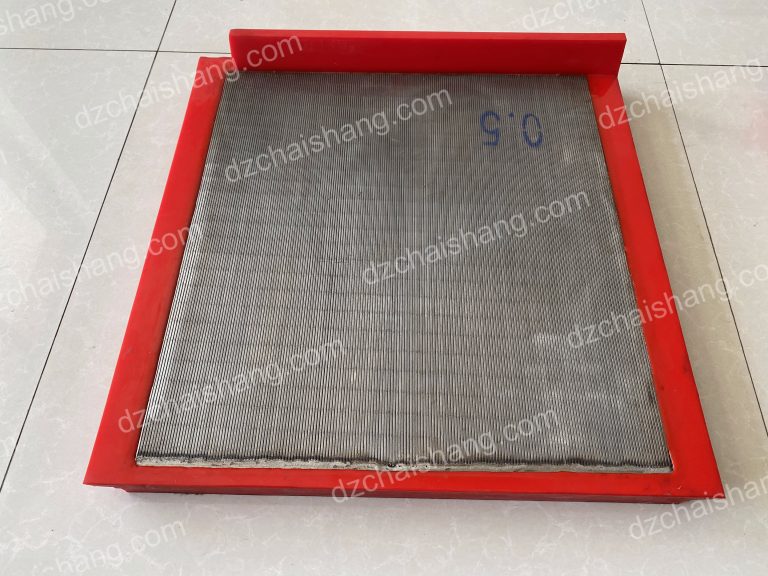

聚氨酯板,俗稱PU振動篩網,已成為各種工業流程中不可或缺的一部分。這些面板以其耐用性、效率和多功能性而聞名,使其成為許多行業的首選。本文旨在闡明 PU 振動篩在工業製程中的功能和用途。 PU振動篩是一種透過振動而設計的篩板,從而分離不同尺寸的物料。振動由電動馬達產生,導致螢幕進行圓週或線性運動。小於網孔的材料落入篩網,而較大的材料保留在頂部。此過程稱為篩分或篩分,廣泛應用於採礦、建築和回收等各個行業。聚氨酯以其耐磨性而聞名,這使其適合篩選礦石和岩石等磨蝕性材料。與金屬篩網不同,PU 篩網不會生鏽或腐蝕,從而延長了其使用壽命並減少了頻繁更換的需要。這不僅節省了成本,還最大限度地減少了工業製程的停機時間。篩網的振動增加了物料通過篩網的速度,從而提高了吞吐量。此外,聚氨酯的柔韌性允許螢幕彎曲和拉伸,這有助於防止阻塞和阻塞。這使得篩分過程更加高效,產量更高。這些篩子可以定制,以適應任何尺寸或形狀的篩分機,使其適合廣泛的應用。此外,網孔的尺寸可以調節,以篩選不同尺寸的材料,從細沙到大岩石。這種靈活性使得業界可以針對不同的製程使用相同類型的篩網,從而減少對多種類型篩網的需求。 。其耐用性、效率和多功能性使其成為篩選不同尺寸材料的經濟高效且可靠的解決方案。無論是在採礦作業中分離礦物、分選建築廢棄物,或是回收廢料,PU 振動篩網都能提供卓越的效能和價值。隨著技術的不斷發展,預計聚氨酯板材在工業過程中的使用將繼續增長,進一步提高這些行業的生產力和效率。

The use of polyurethane Panels in vibrating screens and pu Vibrating mesh is a testament to their versatility and superior properties. However, their applications are not limited to these areas. They are also used in the construction of conveyor belts, wear liners, and other industrial equipment. Their high resistance to wear and tear, excellent load-bearing capacity, and flexibility make them an ideal choice for these applications.

In conclusion, polyurethane panels are a valuable resource in various industries due to their numerous benefits and wide range of applications. Their use in vibrating screens and PU vibrating mesh has revolutionized the separation and classification of materials, improving efficiency and reducing costs. As technology continues to advance, it is expected that the use of polyurethane panels will become even more widespread, further cementing their status as a vital component in various industrial processes.

Understanding the Functionality and Uses of PU Vibrating Mesh in Industrial Processes

Polyurethane panels, commonly known as PU vibrating mesh, have become an integral part of various industrial processes. These panels are renowned for their durability, efficiency, and versatility, making them a preferred choice for many industries. This article aims to shed light on the functionality and uses of PU vibrating mesh in industrial processes.

Polyurethane is a type of polymer that is both flexible and resistant to abrasion, making it ideal for use in vibrating screens. The PU vibrating mesh is a screen panel that is designed to vibrate, thereby separating materials of different sizes. The vibration is generated by an electric motor, which causes the screen to move in a circular or linear motion. The materials that are smaller than the mesh openings fall through the screen, while the larger materials remain on top. This process is known as screening or sieving and is widely used in various industries such as mining, construction, and recycling.

One of the key advantages of using a PU vibrating mesh is its durability. Polyurethane is known for its resistance to wear and tear, which makes it suitable for screening abrasive materials such as ores and rocks. Unlike metal screens, PU screens do not rust or corrode, which extends their lifespan and reduces the need for frequent replacements. This not only saves costs but also minimizes downtime in industrial processes.

Another significant benefit of PU vibrating mesh is its efficiency. The vibration of the screen increases the speed at which materials pass through the mesh, thereby increasing the throughput. Moreover, the flexibility of polyurethane allows the screen to flex and stretch, which helps to prevent blinding and clogging. This results in a more efficient screening process with a higher yield.

The versatility of PU vibrating mesh is another factor that contributes to its widespread use. These screens can be customized to fit any size or shape of the screening machine, making them suitable for a wide range of applications. Furthermore, the size of the mesh openings can be adjusted to screen materials of different sizes, from fine sand to large rocks. This flexibility allows industries to use the same type of screen for different processes, thereby reducing the need for multiple types of screens.

In conclusion, the PU vibrating mesh plays a crucial role in various industrial processes. Its durability, efficiency, and versatility make it a cost-effective and reliable solution for screening materials of different sizes. Whether it’s separating minerals in a mining operation, sorting construction debris, or recycling waste materials, the PU vibrating mesh delivers exceptional performance and value. As technology continues to evolve, it is expected that the use of polyurethane panels in industrial processes will continue to grow, further enhancing productivity and efficiency in these sectors.