探索模組化篩板的功能與優點

了解振動篩與直線振動篩的差異

模組化篩板、振動篩和線性振動篩都是物料搬運和加工產業中不可或缺的組件。儘管功能相似,但這些設備具有明顯的差異,顯著影響它們在不同應用中的效率和有效性。了解這些差異對於操作員和工程師在選擇適合其特定需求的適當設備時做出明智的決定至關重要。 。它由單獨的篩板組成,可以輕鬆更換或重新排列,以滿足不同的篩分要求。此功能使模組化篩板成為需要頻繁改變篩分條件的操作的理想選擇。模組化設計不僅可以快速輕鬆地進行調整,還可以減少停機時間和維護成本。然而,模組化篩板的有效性可能受到其尺寸和可處理材料類型的限制。它由一個馬達組成,使篩子振動,產生圓週運動,有助於均勻地分配和分類材料。振動篩對於處理各種材料(包括濕和乾物質)特別有效。其高頻振動使其能夠根據尺寸有效分離材料,使其成為採礦、建築和回收等行業的熱門選擇。然而,振動篩的效率會受到篩子傾斜度、材料的水分含量和顆粒尺寸等因素的影響。這種類型的篩子通常用於更精細、更精確的材料篩選。直線振動篩採用兩個振動馬達產生一致的力,傳遞到整個篩子。這會產生線性運動,使篩子能夠有效地分離和分類小而輕的顆粒。線性振動篩在食品加工、製藥和化學等精度和衛生至關重要的行業中特別有用。然而,其有效性可能受到篩子尺寸、物料特性和操作條件等因素的限制。獨特的優點和限制。模組化篩板的適應性使其適合需要頻繁改變篩分條件的操作。振動篩的高頻振動使其能夠有效地處理各種材料。直線振動篩的精度使其成為需要精細、衛生篩分的行業的理想選擇。因此,了解這些差異對於為特定應用選擇最合適的設備至關重要。

In conclusion, modular screen plates, vibrator screens, and linear vibrating screens are essential tools in the mining and mineral processing industries. They offer a high degree of efficiency, flexibility, and adaptability, making them invaluable in handling the diverse and demanding requirements of these sectors. By understanding the functionality and benefits of these screens, industry professionals can make informed decisions about their use and application in their operations.

Understanding the Differences between Vibrator Screen and linear vibrating screen

Modular screen plates, vibrator screens, and linear vibrating screens are all integral components in the material handling and processing industry. Despite their similar functions, these devices have distinct differences that significantly impact their efficiency and effectiveness in different applications. Understanding these differences is crucial for operators and engineers to make informed decisions when selecting the appropriate equipment for their specific needs.

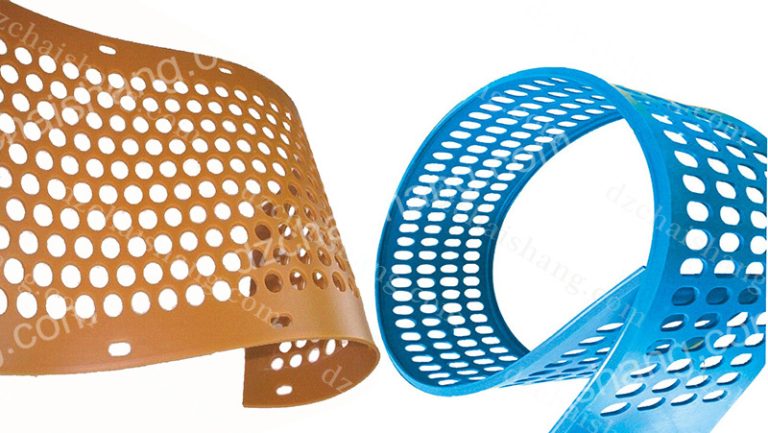

A modular screen plate is a type of screening device that is designed with flexibility and adaptability in mind. It consists of individual screen panels that can be easily replaced or rearranged to suit different screening requirements. This feature makes modular screen plates an ideal choice for operations that require frequent changes in screening conditions. The modular design not only allows for quick and easy adjustments but also reduces downtime and maintenance costs. However, the effectiveness of modular screen plates can be limited by their size and the type of materials they can handle.

On the other hand, a vibrator screen, also known as a vibrating screen, operates by using rotary motion to sift and separate materials. It consists of a motor that causes the screen to vibrate, creating a circular motion that helps to distribute and classify materials evenly. The vibrator screen is particularly effective for handling a wide range of materials, including both wet and dry substances. Its high-frequency vibrations allow it to effectively separate materials based on size, making it a popular choice for industries such as mining, construction, and recycling. However, the vibrator screen’s efficiency can be affected by factors such as the screen’s inclination, the material’s moisture content, and the size of the particles.

The linear vibrating screen, meanwhile, operates on a linear or straight-line motion. This type of screen is typically used for finer, more precise screening of materials. The linear vibrating screen uses two vibrating motors to generate a consistent force, which is transferred to the whole screen. This results in a linear movement that enables the screen to effectively separate and classify small and light particles. The linear vibrating screen is particularly useful in industries such as food processing, pharmaceuticals, and chemicals, where precision and hygiene are paramount. However, its effectiveness can be limited by factors such as the screen’s size, the material’s characteristics, and the operating conditions.

In conclusion, while modular screen plates, vibrator screens, and linear vibrating screens all serve the purpose of separating and classifying materials, they each have their unique advantages and limitations. The modular screen plate’s adaptability makes it suitable for operations that require frequent changes in screening conditions. The vibrator screen’s high-frequency vibrations make it effective for handling a wide range of materials. The linear vibrating screen’s precision makes it ideal for industries that require fine and hygienic screening. Therefore, understanding these differences is crucial for selecting the most suitable equipment for specific applications.