探索礦用篩網在礦物萃取中的效率

聚氨酯板在增強脫水篩性能中的作用

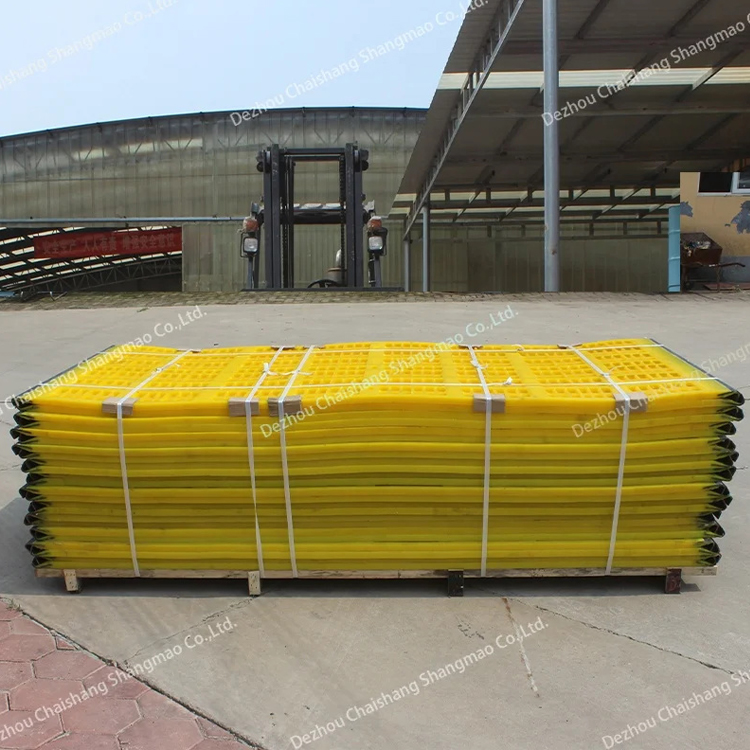

Lastly, the polyurethane panel is a type of screen media used in vibrating screens. It is made from polyurethane, a material known for its excellent abrasion resistance and long service life. The panel is designed with a series of slots or holes, which allow the passage of smaller mineral particles while larger particles are retained.

The polyurethane panel offers several advantages over traditional steel screens. It is lighter, reducing the load on the vibrating screen and increasing its lifespan. It also produces less noise and vibration, improving the working environment. Moreover, the panel’s flexibility allows it to be used in a variety of mining applications, enhancing its efficiency.

In conclusion, the mining screen mesh, dewatering sieve panel, and polyurethane panel are essential tools in mineral extraction. They enhance the efficiency of mining operations by facilitating the separation and processing of valuable minerals. Their durability, adaptability, and ease of maintenance make them ideal for the demanding conditions of the mining industry. As the demand for minerals continues to grow, these tools will undoubtedly continue to play a crucial role in meeting this demand.

The Role of Polyurethane Panels in Enhancing Dewatering Sieve Performance

The mining industry is a critical sector that significantly contributes to the global economy. One of the essential components in this industry is the mining screen mesh, which plays a pivotal role in the separation and sizing of different minerals. However, the efficiency of this process is significantly influenced by the type of material used in the construction of the screen mesh. In recent years, polyurethane panels have emerged as a preferred choice for enhancing the performance of dewatering sieves.

Polyurethane panels are synthetic materials that are known for their durability, flexibility, and resistance to abrasion. These properties make them an ideal choice for use in mining screen meshes. The panels are designed to withstand the harsh conditions of the mining environment, including exposure to abrasive materials, high temperatures, and corrosive substances. This resilience ensures that the panels maintain their structural integrity, thereby enhancing the efficiency and longevity of the dewatering sieves.

The use of polyurethane panels in dewatering sieves also offers significant benefits in terms of operational efficiency. The panels are designed with a unique structure that facilitates the rapid dewatering of materials. This structure includes a series of small holes that allow water to pass through while retaining the solid particles. This efficient separation process results in a higher yield of valuable minerals, thereby increasing the profitability of mining operations.

Moreover, the flexibility of polyurethane panels allows them to be customized to meet the specific needs of different mining operations. They can be designed in various shapes, sizes, and thicknesses to accommodate different types of minerals and varying degrees of abrasion. This adaptability ensures that the panels can be used in a wide range of mining applications, from coal mining to gold mining, and everything in between.

In addition to their operational benefits, polyurethane panels also offer significant cost advantages. While the initial investment may be higher than other materials, the long-term savings are substantial. The durability and resilience of the panels reduce the need for frequent replacements, resulting in lower maintenance costs. Furthermore, the increased efficiency of the dewatering process reduces energy consumption, leading to lower operational costs.

The environmental impact of mining operations is a growing concern in today’s society. Polyurethane panels contribute to sustainable mining practices by reducing waste and conserving resources. The efficient separation process minimizes the amount of waste material, while the durability of the panels reduces the need for new materials. Additionally, the lower energy consumption contributes to a reduction in greenhouse gas emissions.

In conclusion, polyurethane panels play a crucial role in enhancing the performance of dewatering sieves in the mining industry. Their durability, flexibility, and resistance to abrasion make them an ideal choice for use in mining screen meshes. The panels offer significant operational and cost benefits, as well as contributing to sustainable mining practices. As the demand for minerals continues to grow, the use of polyurethane panels in dewatering sieves is set to become increasingly important in the future.