在礦石振動篩中使用模組化PU篩網的優點

如何選擇合適的礦石加工模組化PU篩供應商

在礦石加工方面,選擇合適的模組化聚氨酯 (PU) 篩供應商對於確保營運效率和生產力至關重要。模組化 PU 篩在篩分過程中發揮重要作用,可將有價值的礦石顆粒與不需要的材料分離。市場上有許多供應商提供各種選擇,因此了解如何選擇適合您的特定需求的供應商至關重要。選擇在模組化 PU 篩子製造方面擁有良好業績記錄和多年經驗的供應商可以顯著增加獲得高品質產品的可能性。信譽良好的供應商更有可能遵守嚴格的品質控制標準,確保篩子符合行業規範和標準。配備先進製造設施和技術的供應商更有能力生產耐用、高效且根據您的要求量身定制的模組化 PU 篩子。此外,詢問供應商的品質保證流程,以確保每個篩子在交付給客戶之前都經過徹底的測試。尋找能夠提供多種模組化 PU 篩網選擇的供應商,以適應不同的礦石加工應用和規格。無論您需要篩子進行粗篩、細篩還是脫水,選擇產品系列全面的供應商都可以為您提供更大的靈活性和定制選項。 。每個礦石加工作業都是獨特的,並且可以根據您的特定要求自訂模組化 PU 篩子,可以提高性能和效率。願意與您密切合作以了解您的需求並相應地定制產品的供應商對於優化您的篩選流程至關重要。選擇能夠提供出色客戶支援的供應商,並在需要時提供產品選擇、安裝和故障排除方面的協助。另外,詢問供應商的保固政策和售後服務承諾,以確保購買後可能出現的任何問題都能及時解決。唯一的決定因素。雖然找到提供有競爭力的價格的供應商很重要,但優先考慮品質和可靠性而不是價格。投資高品質的模組化 PU 篩可能需要稍高的前期成本,但可以透過提高性能、耐用性和減少維護費用來實現長期節省。產品和服務有經驗。閱讀評論、推薦和案例研究可以為供應商的聲譽、可靠性和客戶整體滿意度提供有價值的見解。包括聲譽、經驗、製造能力、產品範圍、客製化選項、客戶支援和成本。透過徹底評估這些方面並優先考慮品質和可靠性,您可以選擇滿足您需求並有助於礦石加工業務成功的供應商。

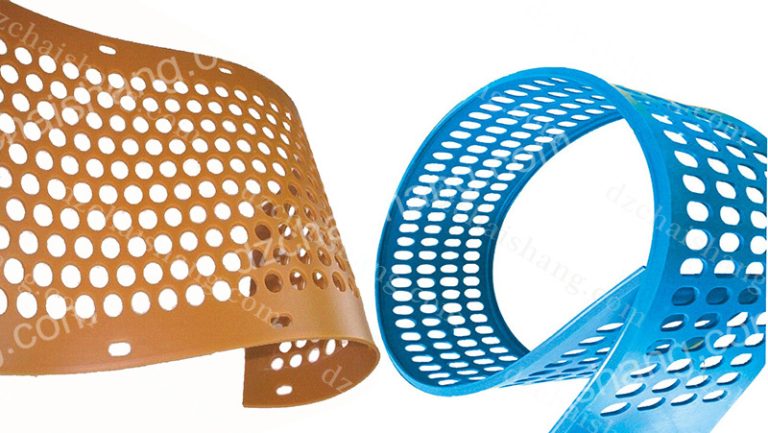

In conclusion, the advantages of using modular PU screens in ore shakers are undeniable. From unparalleled durability and efficiency to versatility and low maintenance requirements, these screens offer a host of benefits that are reshaping the landscape of the ore processing industry. Manufacturers and suppliers alike are increasingly turning to modular PU screens to optimize their operations and drive productivity. As the demand for efficient and cost-effective screening solutions continues to grow, modular PU screens are poised to remain at the forefront of technological innovation in ore processing.

How to Choose the Right Supplier for Modular PU Sieves for Ore Processing

When it comes to ore processing, selecting the right supplier for modular polyurethane (PU) sieves is crucial for ensuring efficiency and productivity in your operations. Modular PU sieves play a significant role in the screening process, separating valuable ore particles from unwanted materials. With numerous suppliers in the market offering various options, it’s essential to know how to choose the right one for your specific needs.

First and foremost, consider the reputation and experience of the supplier. Opting for a supplier with a solid track record and years of experience in manufacturing modular PU sieves can significantly increase the likelihood of receiving high-quality products. A reputable supplier is more likely to adhere to strict quality control standards, ensuring that the sieves meet industry specifications and standards.

Furthermore, assess the supplier’s manufacturing capabilities and technological expertise. A supplier equipped with advanced manufacturing facilities and technology is better positioned to produce modular PU sieves that are durable, efficient, and tailored to your requirements. Additionally, inquire about the supplier’s quality assurance processes to ensure that each sieve undergoes thorough testing before being delivered to customers.

Another crucial factor to consider is the range of products offered by the supplier. Look for a supplier that provides a diverse selection of modular PU sieves to accommodate different ore processing applications and specifications. Whether you require sieves for coarse screening, fine screening, or dewatering, choosing a supplier with a comprehensive product range gives you greater flexibility and customization options.

In addition to product variety, consider the supplier’s ability to offer customization services. Every ore processing operation is unique, and having the option to customize modular PU sieves according to your specific requirements can enhance performance and efficiency. A supplier that is willing to work closely with you to understand your needs and tailor their products accordingly is invaluable in optimizing your screening processes.

Moreover, don’t overlook the importance of customer support and after-sales service. Select a supplier that provides excellent customer support, offering assistance with product selection, installation, and troubleshooting if needed. Additionally, inquire about the supplier’s warranty policies and after-sales service commitments to ensure prompt resolution of any issues that may arise after purchase.

Cost is undoubtedly a significant consideration when choosing a supplier for modular PU sieves, but it should not be the sole determining factor. While it’s essential to find a supplier that offers competitive pricing, prioritize quality and reliability over price alone. Investing in high-quality modular PU sieves may require a slightly higher upfront cost but can result in long-term savings through improved performance, durability, and reduced maintenance expenses.

Finally, take the time to research and gather feedback from other customers who have experience with the supplier’s products and services. Reading reviews, testimonials, and case studies can provide valuable insights into the supplier’s reputation, reliability, and overall satisfaction level among customers.

In conclusion, selecting the right supplier for modular PU sieves for ore processing involves considering various factors, including reputation, experience, manufacturing capabilities, product range, customization options, customer support, and cost. By thoroughly evaluating these aspects and prioritizing quality and reliability, you can choose a supplier that meets your needs and contributes to the success of your ore processing operations.