使用優質聚氨酯振動篩網的好處

如何為您的應用選擇最佳的高品質聚氨酯振動篩網

總而言之,為您的應用選擇最好的高品質聚氨酯振動篩網需要仔細考慮幾個因素。從孔徑尺寸和絲直徑到所使用的聚氨酯類型和篩網的整體設計,在選擇適合您需求的篩網時需要考慮許多因素。花時間仔細評估這些因素並選擇適合您特定應用的篩網,您可以確保您的振動篩網獲得最佳性能和耐用性。

How to Choose the Best High Quality polyurethane vibrating screen mesh for Your Application

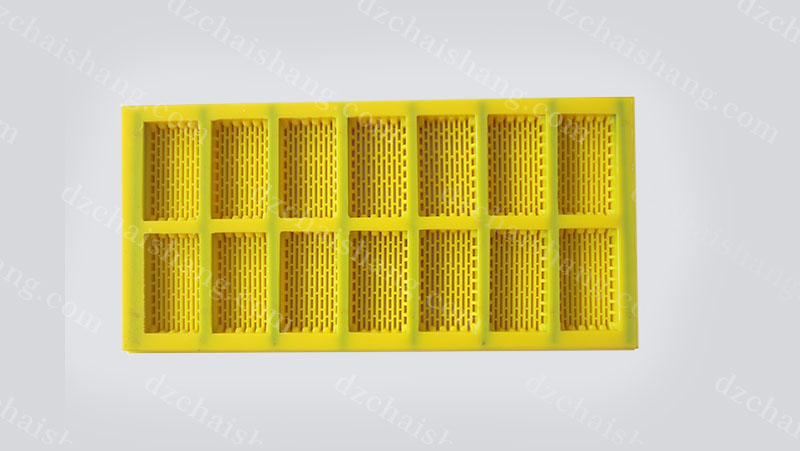

When it comes to choosing the best high-quality polyurethane VIBRATING screen mesh for your application, there are several factors to consider. Polyurethane vibrating screen mesh is a popular choice for many industries due to its durability, flexibility, and resistance to abrasion. However, not all polyurethane vibrating screen mesh is created equal, and it’s important to select the right type for your specific needs.

One of the first things to consider when choosing polyurethane vibrating screen mesh is the aperture size. The aperture size refers to the space between the wires in the mesh, and it can have a significant impact on the performance of the screen. A smaller aperture size is ideal for applications where fine particles need to be separated, while a larger aperture size is better suited for larger particles. It’s important to consider the size of the particles you will be working with when selecting the aperture size of the mesh.

Another important factor to consider is the wire diameter of the polyurethane vibrating screen mesh. The wire diameter refers to the thickness of the wires used to create the mesh, and it can affect the strength and durability of the screen. Thicker wires are more durable and can withstand heavier loads, while thinner wires are more flexible and can provide better screening performance. It’s important to choose a wire diameter that is appropriate for the type of material you will be screening and the amount of wear and tear the screen will be subjected to.

In addition to aperture size and wire diameter, it’s also important to consider the type of polyurethane used in the vibrating screen mesh. There are different types of polyurethane available, each with its own unique properties and advantages. For example, some types of polyurethane are more resistant to abrasion, while others are more flexible and can provide better screening performance. It’s important to choose a type of polyurethane that is best suited for your specific application and will provide the durability and performance you need.

When selecting polyurethane vibrating screen mesh, it’s also important to consider the overall design of the screen. The design of the screen can affect its performance and efficiency, so it’s important to choose a design that is well-suited for your specific application. Some screens are designed with a higher open area, which allows for better screening efficiency and throughput, while others are designed with a tighter weave for better particle separation. It’s important to consider the design of the screen and how it will impact the performance of your application.

In conclusion, choosing the best high-quality polyurethane vibrating screen mesh for your application requires careful consideration of several factors. From aperture size and wire diameter to the type of polyurethane used and the overall design of the screen, there are many factors to consider when selecting the right mesh for your needs. By taking the time to carefully evaluate these factors and choose a mesh that is well-suited for your specific application, you can ensure that you get the best performance and durability from your vibrating screen mesh.