Benefits of Using polyurethane High-Frequency screens in mining Operations

Polyurethane high-frequency screens have become increasingly popular in the mining industry due to their unique advantages and versatile application fields. These screens offer a range of benefits that make them a preferred choice for many mining operations. In this article, we will explore the advantages of using polyurethane high-frequency screens and the various application fields where they excel.

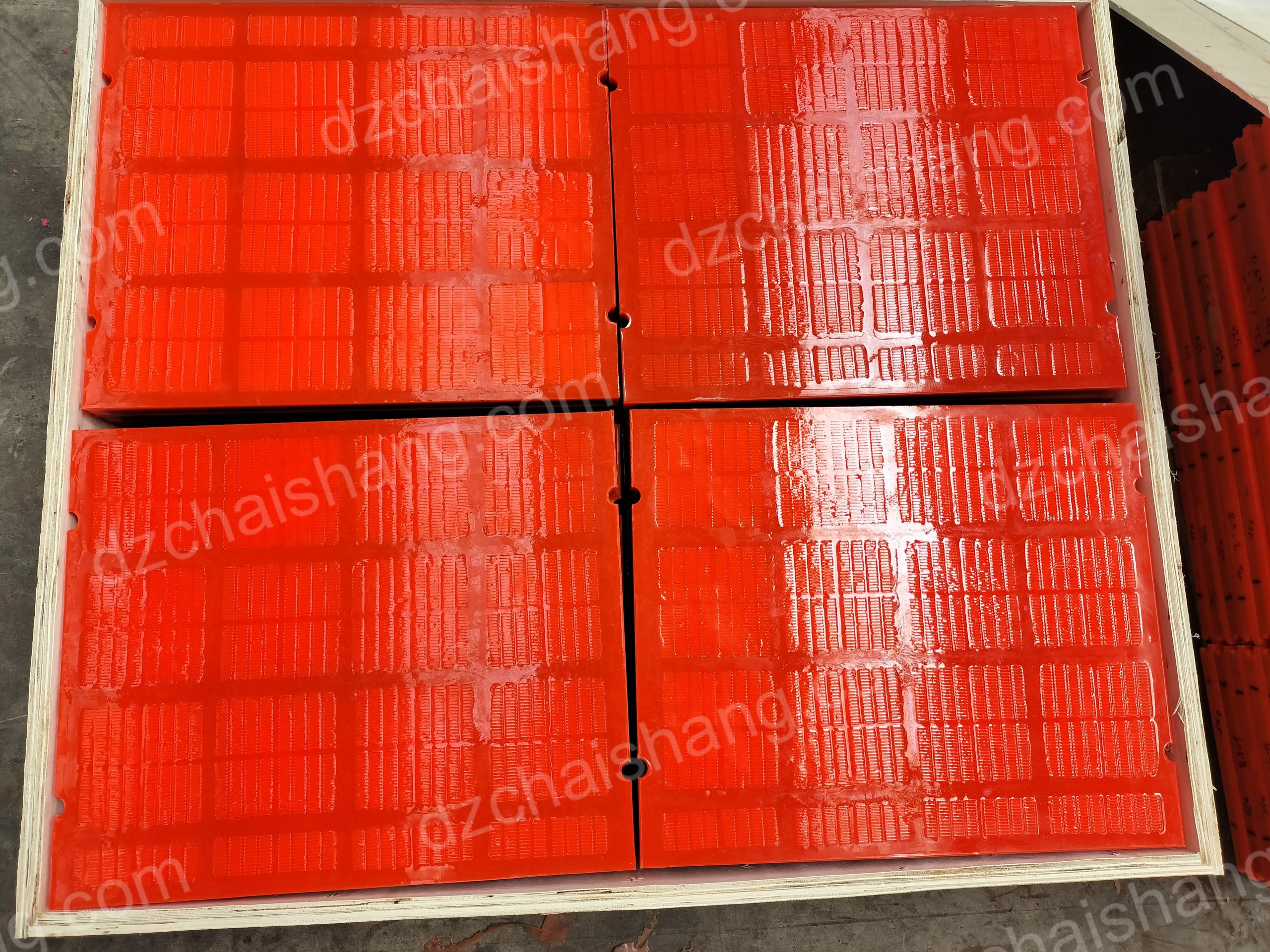

One of the key advantages of polyurethane high-frequency screens is their durability. These screens are made from a tough and resilient material that can withstand the harsh conditions often found in mining operations. They are resistant to abrasion, corrosion, and impact, making them ideal for use in high-wear applications. This durability ensures that polyurethane high-frequency screens have a long service life, reducing the need for frequent replacements and maintenance.

In addition to their durability, polyurethane high-frequency screens also offer excellent screening efficiency. These screens are designed to provide high-frequency vibrations that help to separate materials more effectively. This results in a more efficient screening process, with increased throughput and reduced downtime. The high-frequency vibrations also help to prevent blinding and pegging, ensuring a consistent and reliable screening performance.

Another advantage of polyurethane high-frequency screens is their versatility. These screens can be customized to meet the specific requirements of different applications. They are available in a range of sizes and configurations, allowing them to be tailored to the needs of individual mining operations. Polyurethane high-frequency screens can also be easily installed and maintained, making them a cost-effective solution for many mining companies.

Polyurethane high-frequency screens are commonly used in a variety of application fields within the mining industry. One of the primary uses of these screens is in the classification of minerals and aggregates. The high-frequency vibrations of the screens help to separate materials based on size, ensuring that the final product meets the desired specifications. Polyurethane high-frequency screens are also used in dewatering applications, where they help to remove excess moisture from materials before further processing.

In addition to their use in mineral processing, polyurethane high-frequency screens are also employed in the recycling industry. These screens are used to separate recyclable materials such as plastics, paper, and metals, helping to increase the efficiency of recycling operations. Polyurethane high-frequency screens are also used in the food and chemical industries, where they help to separate and classify a wide range of materials.

Overall, polyurethane high-frequency screens offer a range of advantages that make them a valuable asset in mining operations. Their durability, screening efficiency, and versatility make them a preferred choice for many companies looking to improve their screening processes. With their ability to withstand harsh conditions and provide reliable performance, polyurethane high-frequency screens are an essential tool for achieving optimal results in the mining industry.

Applications of Polyurethane High-Frequency Screens in Aggregate Processing Industries

Polyurethane high-frequency screens have become increasingly popular in the aggregate processing industries due to their unique advantages and versatile applications. These screens are made from polyurethane material, which offers several benefits over traditional screens made from steel or other materials. In this article, we will explore the advantages of polyurethane high-frequency screens and their various application fields in aggregate processing industries.

One of the key advantages of polyurethane high-frequency screens is their durability. Polyurethane is a highly durable material that can withstand harsh operating conditions, including high temperatures, abrasive materials, and heavy loads. This durability ensures that polyurethane screens have a longer lifespan compared to traditional screens, reducing maintenance costs and downtime for aggregate processing plants.

In addition to their durability, polyurethane high-frequency screens also offer superior wear resistance. The material is resistant to abrasion, impact, and corrosion, making it ideal for screening applications where wear and tear are common. This wear resistance ensures that polyurethane screens maintain their performance and efficiency over time, providing consistent and reliable screening results for aggregate processing plants.

Another advantage of polyurethane high-frequency screens is their flexibility. Polyurethane is a flexible material that can be molded into various shapes and sizes to meet specific screening requirements. This flexibility allows for the customization of screen panels to fit different screening applications, including scalping, sizing, dewatering, and washing. Polyurethane screens can also be easily installed and replaced, reducing downtime and improving overall efficiency in aggregate processing plants.

Polyurethane high-frequency screens are also known for their high screening efficiency. The material has a high open area, which allows for increased throughput and improved screening performance. This high screening efficiency results in higher production rates and better product quality for aggregate processing plants, ultimately leading to increased profitability and competitiveness in the industry.

In terms of application fields, polyurethane high-frequency screens are widely used in various aggregate processing industries, including mining, quarrying, construction, and recycling. These screens are commonly used for screening and separating materials such as sand, gravel, crushed stone, and recycled aggregates. They are also used in applications where fine screening and dewatering are required, such as in the production of concrete, asphalt, and other construction materials.

Polyurethane high-frequency screens are particularly well-suited for wet screening applications, as the material is resistant to moisture and can withstand high-frequency vibrations. This makes them ideal for use in wet processing plants, where water is used to wash and separate materials during the screening process. Polyurethane screens can effectively remove fines and oversize particles from the feed material, resulting in a cleaner and more uniform product for further processing.

Overall, polyurethane high-frequency screens offer a range of unique advantages and applications in aggregate processing industries. Their durability, wear resistance, flexibility, and high screening efficiency make them a popular choice for screening operations in various industries. With their ability to improve screening performance, reduce maintenance costs, and increase production rates, polyurethane screens are a valuable investment for aggregate processing plants looking to enhance their operations and achieve greater success in the competitive market.