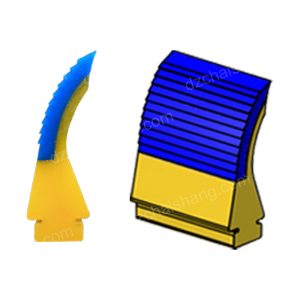

200×200 mm Segmented scraper

Material: Polyurethane

Hardness: 80-95 Shore A

Size: Can be customized

Customization: Available

Standard service life: 6~12 months

Delivery: 15-45 days depending on the quantity

- Satisfaction Guaranteed

- Accurate dimensions

- Guaranteed installation

- On-time delivery

product description

polyurethane scraper, also called polyurethane cleaner, has high wear resistance, aging resistance, solvent resistance, and long service life. Depending on the usage environment, the product hardness has a wide range of options: ShoreA40-ShoreA95. Products with different hardness and materials can be selected for different working conditions. Polyurethane scrapers, also called PU scrapers, are used on coal and chemical conveyor belts to remove

adhered ash and powder materials, such as coal transportation, fertilizer transportation, sand and gravel transportation, etc.

The belt cleaning system is suitable for efficient cleaning of conveyor belts carrying fine powder materials, dry materials or slightly wet materials, as well as inclined conveyors with splints.

The cleaner is made of polymer polyurethane, which has low friction coefficient, high wear resistance, high strength, stable scraping effect, anti-corrosion and anti-breakage, and will not damage the belt. Suitable for electricity

Conveyor belts in various industries such as metallurgy and mining.

The cleaner has a buffering function and can follow the belt surface well under various circumstances, producing a complete scraping effect.

Features

1. The cleaner scraper is of standardized design, with good interchangeability, light weight, and easy and fast installation, maintenance and replacement.

2. Effectively eliminate material return.

3. Reduced materials.

4. Reduce maintenance time and costs.

5. Fewer blade changes means less downtime.

6. The service life is more than 3-4 times that of metal rubber scrapers.

We can customize scrapers according to customer needs, up to 2 meters long.

The latch-type blade makes blade replacement simple and only takes one minute, no tools required, from the outside of the hood.

Super wear-resistant polyurethane composite material has a service life that is twice that of ordinary polyurethane. It has excellent wear resistance and has a service life that is five times that of ordinary rubber plastic products. Can be customized according to customer drawing requirements. The PU scrapers produced by our company are all made of casting molding. Various types of products are easy to install, maintain and debug, do not damage the belt, do not hold objects, do not stick to materials, have good cleaning effects, good toughness, good straightness, and high Wear resistance and other characteristics.

Widely used in electric power, mining, coal, conveying machinery, cleaning and other industries.