Understanding polyurethane screen panel: Frequently Asked Questions

polyurethane screen panels are an essential component in many industrial processes, particularly in the mining and aggregate industries. Despite their widespread use, many people still have questions about these panels, their uses, and their benefits. This article aims to address some of the most frequently asked questions about polyurethane screen panels.

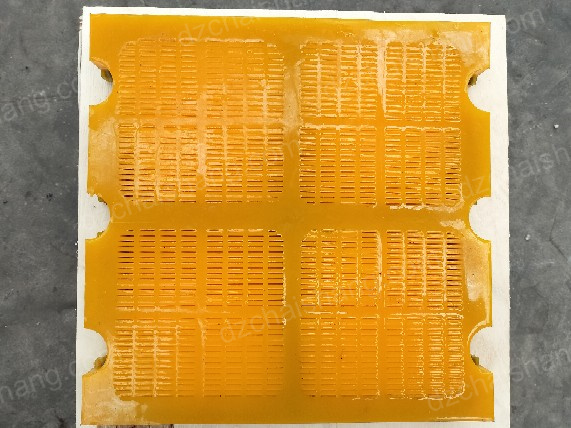

One of the most common questions is, “What exactly is a polyurethane screen panel?” Simply put, a polyurethane screen panel is a screening surface made from polyurethane, a type of polymer. These panels are used in various screening applications to separate different sizes of particles. They are known for their durability, flexibility, and ability to resist abrasion and corrosion.

Another frequently asked question is, “Why use polyurethane instead of other materials?” The answer lies in the unique properties of polyurethane. This material is incredibly durable and resistant to wear and tear, making it ideal for heavy-duty applications. It can withstand high levels of mechanical stress and is resistant to various environmental factors such as UV radiation and temperature fluctuations. Furthermore, polyurethane screen panels offer excellent noise and vibration reduction, making them a preferred choice in many industrial settings.

Many people also wonder, “What are the different types of polyurethane screen panels?” There are several types, each designed for specific applications. For instance, modular screen panels are easy to install and replace, making them ideal for situations where frequent screen changes are necessary. tensioned screen panels, on the other hand, are designed for high-capacity screening, while flip-flow screens are best for screening damp or wet materials.

“How long do polyurethane screen panels last?” is another common query. The lifespan of these panels can vary greatly depending on the specific application and operating conditions. However, due to their high wear resistance, polyurethane screen panels typically have a longer service life compared to other screening materials. Regular maintenance and inspection can further extend their lifespan.

The question of cost is always a concern, with many asking, “Are polyurethane screen panels expensive?” While the initial cost of these panels may be higher than other materials, their long lifespan and durability often result in lower long-term costs. The reduced need for replacement and maintenance can lead to significant savings over time.

Lastly, a common question is, “Where can I purchase polyurethane screen panels?” These panels are available from various suppliers and manufacturers. When choosing a supplier, it’s important to consider factors such as the quality of the panels, the supplier’s reputation, and the after-sales service provided.

In conclusion, polyurethane screen panels are a versatile and durable solution for various screening applications. Their unique properties make them a preferred choice in many industries, offering benefits such as high wear resistance, noise reduction, and long service life. While the initial cost may be higher, the long-term savings and performance benefits make them a worthwhile investment. Whether you’re in the mining industry, the aggregate industry, or any other industry that requires screening, polyurethane screen panels can provide a reliable and efficient solution.