Advantages of polyurethane screens over Traditional Screens

Advantages of Polyurethane Screens over Traditional Screens

Polyurethane screens have gained popularity in various industries due to their numerous advantages over traditional screens. These screens, made from a synthetic material called polyurethane, offer several benefits that make them a preferred choice for many applications.

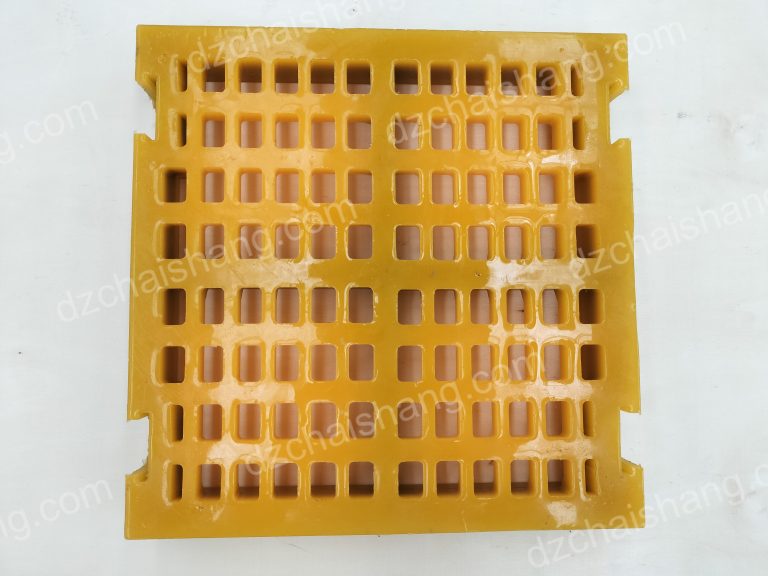

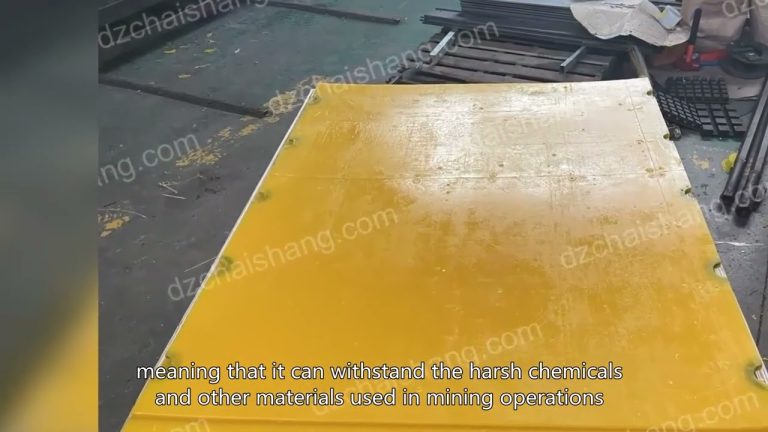

One of the key advantages of polyurethane screens is their durability. Unlike traditional screens, which are often made from materials like steel or rubber, polyurethane screens are highly resistant to wear and tear. This means that they can withstand the harsh conditions of heavy-duty applications without losing their effectiveness. Whether it’s in mining, construction, or recycling, polyurethane screens can handle the demands of these industries with ease.

Another advantage of polyurethane screens is their flexibility. Traditional screens are often rigid and inflexible, limiting their ability to adapt to different materials and conditions. Polyurethane screens, on the other hand, are highly flexible and can be easily molded into various shapes and sizes. This flexibility allows them to fit perfectly into different screening machines and ensures optimal performance.

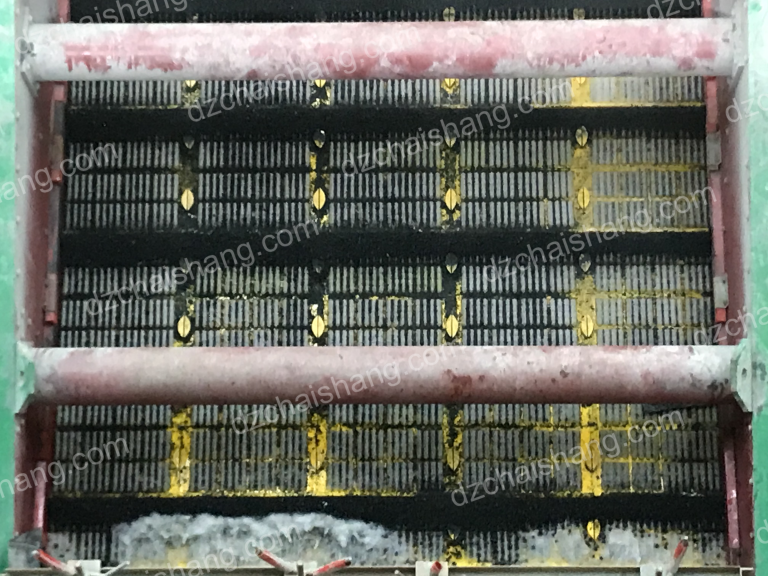

Polyurethane screens also offer superior screening efficiency compared to traditional screens. The unique properties of polyurethane, such as its high elasticity and resilience, enable these screens to effectively separate particles of different sizes. This means that they can achieve a higher screening accuracy and produce cleaner, more precise results. Whether it’s separating fine particles in mining operations or classifying materials in industrial processes, polyurethane screens deliver exceptional performance.

In addition to their durability, flexibility, and screening efficiency, polyurethane screens also have excellent self-cleaning properties. Traditional screens often suffer from blinding or clogging, where particles get trapped in the screen openings, reducing their effectiveness. Polyurethane screens, however, have a smooth surface that prevents material buildup and allows for easy cleaning. This self-cleaning feature not only improves the overall efficiency of the screening process but also reduces downtime for maintenance and increases productivity.

Furthermore, polyurethane screens are known for their noise reduction capabilities. Traditional screens can generate significant noise during operation, which can be disruptive and potentially harmful to workers’ health. Polyurethane screens, on the other hand, absorb and dampen vibrations, resulting in quieter operation. This not only creates a more comfortable working environment but also contributes to better overall safety.

Lastly, polyurethane screens are environmentally friendly. Traditional screens often require regular replacement due to wear and tear, resulting in increased waste and environmental impact. Polyurethane screens, on the other hand, have a longer lifespan and can be recycled at the end of their useful life. This reduces the need for constant replacements and minimizes waste generation, making them a more sustainable choice.

In conclusion, polyurethane screens offer several advantages over traditional screens. Their durability, flexibility, screening efficiency, self-cleaning properties, noise reduction capabilities, and environmental friendliness make them a superior choice for various industries. Whether it’s in mining, construction, or recycling, polyurethane screens provide optimal performance and contribute to improved productivity and sustainability. As industries continue to evolve, the demand for polyurethane screens is expected to grow, further solidifying their position as the preferred choice for screening applications.