How Vibrating PU Media and Tension Panels Can Improve Dewatering Efficiency and Reduce Costs

Dewatering is an essential part of many industrial processes, and it’s important to ensure that it’s done efficiently and cost-effectively. Fortunately, there are a number of ways to improve dewatering efficiency and reduce costs, including the use of vibrating PU media and tension panels.

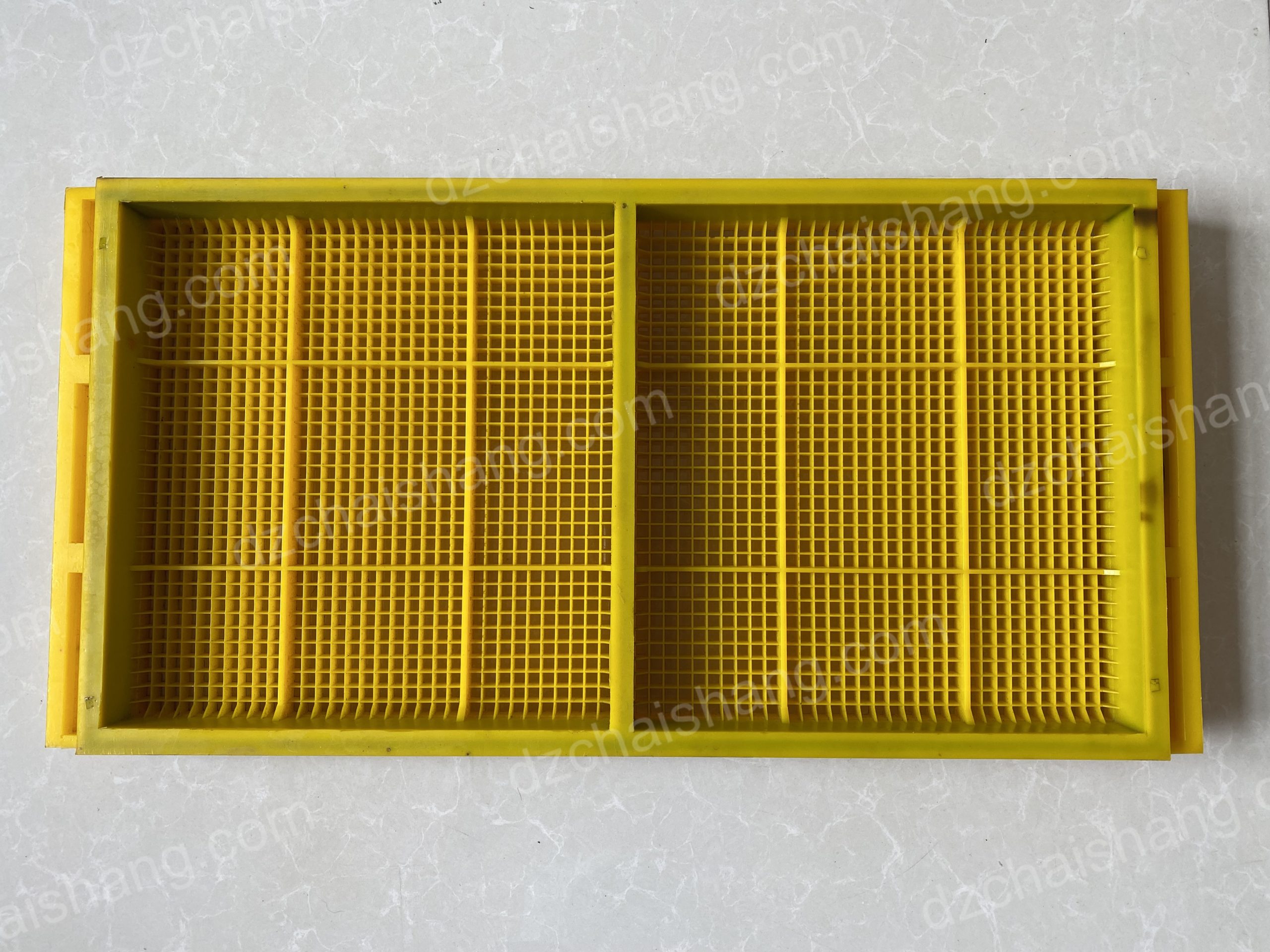

Vibrating PU media is a type of polyurethane media that is used in dewatering applications. It is designed to vibrate at a specific frequency, which helps to separate solids from liquids. This vibration helps to reduce the amount of time and energy required to dewater a material, resulting in improved efficiency and cost savings.

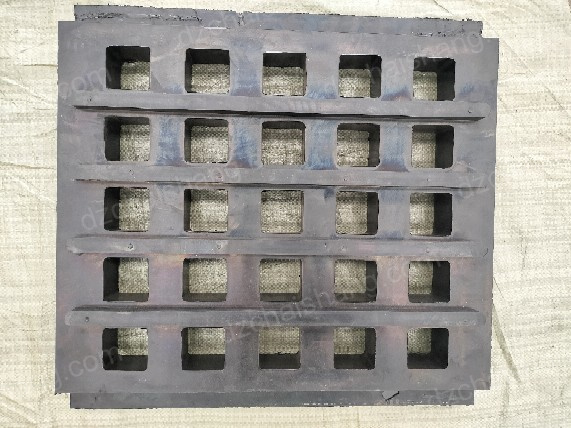

Tension panels are also used in dewatering applications. These panels are designed to create a tension force on the material being dewatered, which helps to separate the solids from the liquids. This tension force helps to reduce the amount of time and energy required to dewater a material, resulting in improved efficiency and cost savings.

The combination of vibrating PU media and tension panels can be an effective way to improve dewatering efficiency and reduce costs. The vibrating PU media helps to separate solids from liquids, while the tension panels create a tension force that helps to further separate the solids from the liquids. This combination of technologies can help to reduce the amount of time and energy required to dewater a material, resulting in improved efficiency and cost savings.

Overall, vibrating PU media and tension panels can be an effective way to improve dewatering efficiency and reduce costs. By using these technologies, you can reduce the amount of time and energy required to dewater a material, resulting in improved efficiency and cost savings.