Benefits of Using High Quality Flip-Flow polyurethane screen mesh

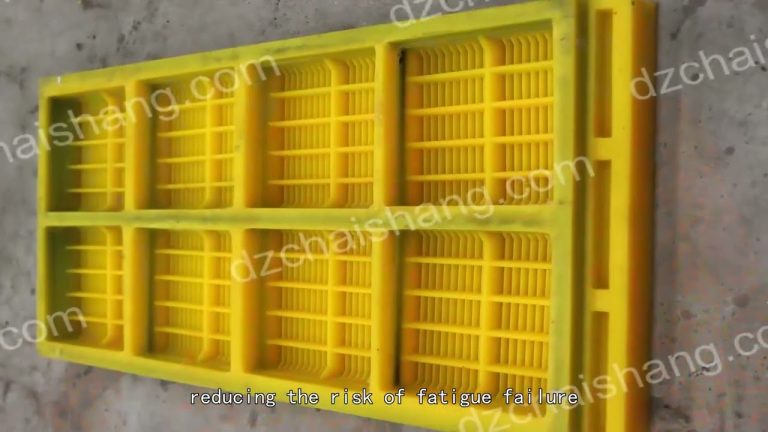

High quality flip-flow polyurethane screen mesh is a crucial component in vibrating screens, as it plays a significant role in the screening process. This type of screen mesh is known for its durability, flexibility, and efficiency, making it a popular choice for various industries. In this article, we will discuss the benefits of using high quality flip-flow polyurethane screen mesh in vibrating screens. One of the key advantages of using high quality flip-flow polyurethane screen mesh is its superior durability. Unlike traditional screen mesh materials such as steel or rubber, polyurethane is highly resistant to wear and tear, making it ideal for heavy-duty applications. This means that the screen mesh will last longer and require less frequent replacement, ultimately saving time and money for businesses. In addition to its durability, high quality flip-flow polyurethane screen mesh is also known for its flexibility. This type of screen mesh can easily adapt to the changing conditions of the screening process, ensuring efficient and effective screening of materials. The flexibility of polyurethane screen mesh allows for better screening performance, resulting in higher productivity and reduced downtime. Another benefit of using high quality flip-flow polyurethane screen mesh is its efficiency. Polyurethane screen mesh is designed to allow for maximum throughput and screening efficiency, ensuring that materials are properly screened and separated. This leads to improved product quality and reduced waste, ultimately increasing the overall efficiency of the screening process. Furthermore, high quality flip-flow polyurethane screen mesh is easy to install and maintain. Unlike traditional screen mesh materials that require frequent maintenance and replacement, polyurethane screen mesh is low maintenance and easy to clean. This means that businesses can save time and resources on maintenance, allowing for more efficient operation of vibrating screens.

Additionally, high quality flip-flow polyurethane screen mesh is environmentally friendly. Polyurethane is a recyclable material, making it a sustainable choice for businesses looking to reduce their environmental impact. By using polyurethane screen mesh, businesses can contribute to a more sustainable future while still maintaining high-quality screening performance. Overall, the benefits of using high quality flip-flow polyurethane screen mesh in vibrating screens are clear. From its superior durability and flexibility to its efficiency and ease of maintenance, polyurethane screen mesh offers a range of advantages for businesses in various industries. By investing in high quality flip-flow polyurethane screen mesh, businesses can improve their screening processes, increase productivity, and reduce costs in the long run.

How to Properly Maintain and Clean Flip-Flow Polyurethane Screen Mesh

Flip-flow polyurethane screen mesh is a popular choice for vibrating screens due to its durability and efficiency in separating materials. However, like any other equipment, proper maintenance and cleaning are essential to ensure its longevity and optimal performance. In this article, we will discuss how to properly maintain and clean flip-flow polyurethane screen mesh to maximize its effectiveness. Regular maintenance is key to keeping flip-flow polyurethane screen mesh in top condition. One of the most important steps in maintaining this type of screen mesh is to regularly inspect it for any signs of wear or damage. Look for tears, holes, or any other defects that may affect its performance. If any issues are found, they should be addressed promptly to prevent further damage. In addition to visual inspections, it is also important to regularly clean flip-flow polyurethane screen mesh to remove any buildup of material or debris. Over time, particles can become trapped in the mesh, reducing its effectiveness in separating materials. To clean the screen mesh, simply remove it from the vibrating screen and wash it with water and a mild detergent. Avoid using harsh chemicals or abrasive cleaners, as they can damage the polyurethane material. After cleaning the screen mesh, allow it to dry completely before reinstalling it in the vibrating screen. This will help prevent mold or mildew from forming on the mesh. It is also a good idea to inspect the screen mesh again after cleaning to ensure that all debris has been removed. In addition to regular maintenance and cleaning, there are a few other tips to help prolong the life of flip-flow polyurethane screen mesh. One important tip is to avoid overloading the vibrating screen with material. Excessive material can put strain on the screen mesh, leading to premature wear and tear. It is also important to operate the vibrating screen at the proper speed and amplitude to prevent unnecessary stress on the mesh. Another tip is to store flip-flow polyurethane screen mesh properly when not in use. Store the mesh in a cool, dry place away from direct sunlight and extreme temperatures. This will help prevent the material from degrading over time. By following these maintenance and cleaning tips, you can help ensure that your flip-flow polyurethane screen mesh remains in top condition and continues to perform efficiently. Regular inspections, cleaning, and proper storage are key to maximizing the lifespan of this valuable equipment. Remember to address any issues promptly and avoid overloading or operating the vibrating screen at improper speeds to prevent unnecessary wear and tear on the screen mesh. In conclusion, flip-flow polyurethane screen mesh is a durable and efficient option for vibrating screens. Proper maintenance and cleaning are essential to ensure its longevity and optimal performance. By following the tips outlined in this article, you can help prolong the life of your screen mesh and keep your vibrating screen operating at its best.Comparison of Flip-Flow Polyurethane Screen Mesh with Traditional Screen Mesh Materials

Polyurethane screen mesh has become increasingly popular in the mining and aggregate industries due to its durability and efficiency. One type of polyurethane screen mesh that has gained significant attention is the flip-flow polyurethane screen mesh. This article aims to compare flip-flow polyurethane screen mesh with traditional screen mesh materials, highlighting the advantages and disadvantages of each. Traditional screen mesh materials, such as woven wire or steel plate, have been widely used in vibrating screens for many years. These materials are known for their strength and ability to withstand heavy loads. However, they also have some drawbacks. For instance, Woven wire mesh can easily become clogged with fine particles, reducing the screening efficiency. Steel plate mesh, on the other hand, is prone to corrosion and requires regular maintenance. Flip-flow polyurethane screen mesh, on the other hand, offers several advantages over traditional screen mesh materials. Firstly, it is highly resistant to abrasion, making it ideal for screening abrasive materials. This durability ensures a longer lifespan for the screen mesh, reducing the need for frequent replacements and saving costs in the long run. Another advantage of flip-flow polyurethane screen mesh is its ability to effectively screen wet and sticky materials. The unique design of the mesh allows for the efficient drainage of water, preventing blinding and clogging. This is particularly beneficial in applications where moisture content is high, such as in the coal and aggregate industries. Furthermore, flip-flow polyurethane screen mesh offers excellent screening efficiency. The flexible Polyurethane Panels allow for the efficient separation of particles, ensuring accurate sizing and reducing the risk of oversize material passing through the screen. This results in improved product quality and increased productivity. In addition to its performance benefits, flip-flow polyurethane screen mesh is also easy to install and maintain. The modular design of the mesh panels allows for quick and simple replacement, minimizing downtime and maximizing operational efficiency. Moreover, the self-cleaning properties of polyurethane prevent the accumulation of material on the screen surface, reducing the need for manual cleaning. Despite its numerous advantages, flip-flow polyurethane screen mesh does have some limitations. One of the main drawbacks is its higher initial cost compared to traditional screen mesh materials. However, considering the long-term benefits and cost savings, this initial investment is often justified. Another limitation is the limited range of opening sizes available for flip-flow polyurethane screen mesh. While traditional screen mesh materials offer a wide range of opening sizes, flip-flow polyurethane screen mesh is typically available in a narrower range. This may limit its suitability for certain applications that require specific opening sizes.In conclusion, flip-flow polyurethane screen mesh offers several advantages over traditional screen mesh materials. Its durability, ability to screen wet and sticky materials, and high screening efficiency make it a preferred choice in the mining and aggregate industries. While it may have a higher initial cost and limited opening size range, the long-term benefits and cost savings outweigh these limitations. Overall, flip-flow polyurethane screen mesh is a high-quality option for vibrating screens, providing improved performance and productivity.