Exploring the Benefits of Using polyurethane Media in high frequency Deck Vibrating Modular Manufacture

When it comes to high frequency deck vibrating modular manufacture, polyurethane media is a great choice. Not only is it incredibly durable and long-lasting, but it also offers a number of benefits that make it an ideal choice for this type of manufacturing.

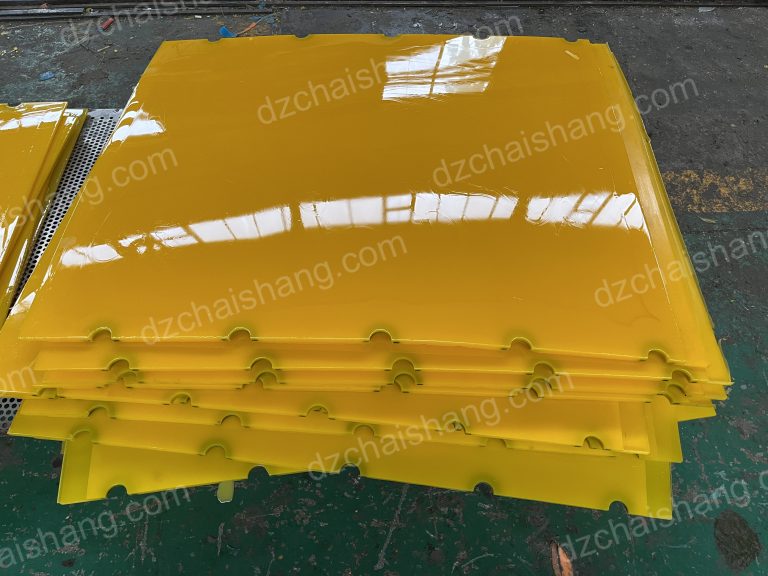

For starters, polyurethane media is incredibly lightweight, making it easy to transport and install. This makes it ideal for high frequency deck vibrating modular manufacture, as it can be quickly and easily moved around the factory floor. Additionally, polyurethane media is incredibly flexible, allowing it to be used in a variety of different shapes and sizes. This makes it perfect for creating custom-shaped parts and components.

Another great benefit of using polyurethane media in high frequency deck vibrating modular manufacture is its ability to absorb sound and vibration. This makes it ideal for reducing noise levels in the factory, which can be a major issue in some manufacturing environments. Additionally, polyurethane media is incredibly resistant to wear and tear, meaning it can withstand the rigors of high frequency deck vibrating modular manufacture without any issues.

Finally, polyurethane media is incredibly cost-effective. It is much cheaper than other materials used in high frequency deck vibrating modular manufacture, making it a great choice for those looking to save money.

Overall, polyurethane media is an excellent choice for high frequency deck vibrating modular manufacture. It is lightweight, flexible, and incredibly durable, making it perfect for creating custom-shaped parts and components. Additionally, it is incredibly cost-effective and can help reduce noise levels in the factory. With all these benefits, it’s no wonder why polyurethane media is becoming increasingly popular in the manufacturing industry.

Understanding the Advantages of Polyurethane Media in Manufacturer PU High Frequency Deck Vibrating Modular Mineral Processing

When it comes to mineral processing, manufacturers are always looking for ways to improve their efficiency and productivity. One of the most effective solutions is to use polyurethane media in their high frequency deck vibrating modular mineral processing systems. This type of media offers a number of advantages that can help manufacturers get the most out of their mineral processing operations.

First, polyurethane media is incredibly durable and long-lasting. This means that manufacturers can rely on their vibrating modular mineral processing systems to run smoothly and efficiently for years to come. Additionally, polyurethane media is resistant to wear and tear, so it won’t need to be replaced as often as other types of media. This can help manufacturers save money in the long run.

Second, polyurethane media is incredibly effective at separating different types of minerals. This is because the media is designed to vibrate at a high frequency, which helps to separate the minerals more quickly and efficiently. This can help manufacturers get the most out of their mineral processing operations.

Finally, polyurethane media is incredibly easy to maintain. This means that manufacturers don’t have to worry about spending a lot of time and money on maintenance and repairs. This can help them save money in the long run and keep their mineral processing operations running smoothly.

Overall, polyurethane media is an excellent choice for manufacturers looking to get the most out of their mineral processing operations. It is incredibly durable, effective, and easy to maintain, which makes it a great choice for any mineral processing system. So, if you’re looking for a way to improve your mineral processing operations, consider using polyurethane media in your high frequency deck vibrating modular mineral processing systems. You’ll be glad you did!