Het belang van fijne urethaanplaten in mijnbouwactiviteiten begrijpen

Het directe spansysteem dat wordt gebruikt in urethaandektoepassingen verbetert de prestaties en levensduur ervan nog verder. Door de noodzaak van traditionele bevestigingsmethoden zoals bouten of clips te elimineren, minimaliseert dit systeem spanningsconcentraties en potentiële faalpunten. Als gevolg hiervan zijn urethaandekken bestand tegen hogere belastingen en kunnen ze op hogere snelheden werken zonder de integriteit in gevaar te brengen, waardoor de uptime en productiviteit worden gemaximaliseerd.

De voordelen van fijne urethaanplaten reiken verder dan operationele efficiëntie en omvatten ook milieuoverwegingen. Vergeleken met traditionele materialen zoals staal biedt urethaan een superieure corrosieweerstand, waardoor het risico op verontreiniging door roest of corrosieproducten wordt verminderd. Bovendien is urethaan niet giftig en inert, waardoor het gedurende de gehele levenscyclus een minimale impact op het milieu heeft. Dit komt overeen met de groeiende nadruk op duurzame praktijken binnen de mijnbouwsector, wat de relevantie van fijne urethaanplaten in moderne mijnbouwactiviteiten verder onderstreept.

Concluderend: fijne urethaanplaten spelen een cruciale rol bij het verbeteren van de efficiëntie, betrouwbaarheid en duurzaamheid van de mijnbouw activiteiten. Hun uitzonderlijke duurzaamheid, veelzijdigheid en prestaties maken ze tot onmisbare componenten in screening-, sorteer- en classificatieprocessen. Naarmate de mijnbouwindustrie zich blijft ontwikkelen, wordt verwacht dat de vraag naar innovatieve oplossingen zoals fijne urethaanplaten zal stijgen, wat verdere ontwikkelingen en toepassingen in het veld zal stimuleren.

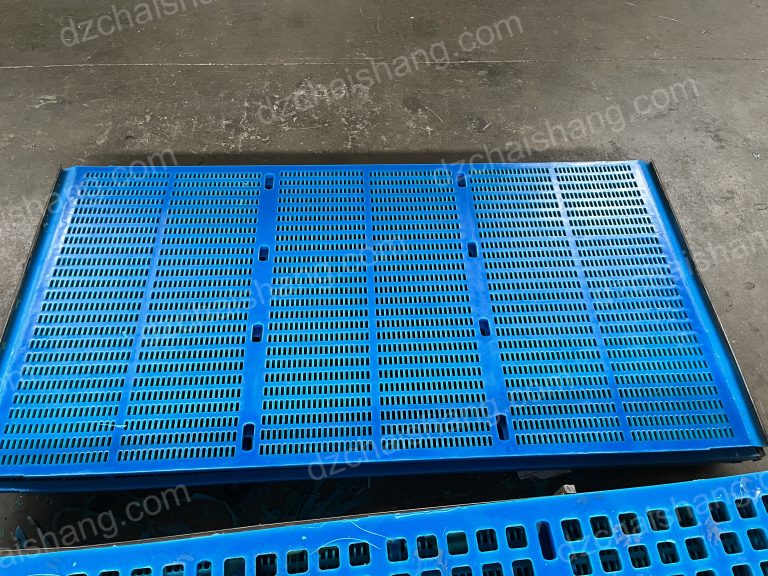

One of the primary applications of urethane fine plates in mining is in screening operations. These plates are commonly used in vibrating screens, where they serve as the screening surface. Their high abrasion resistance enables them to withstand the constant friction and impact from the materials being processed, thereby maintaining screening efficiency over extended periods. Additionally, their flexibility allows them to conform to the contours of the screen deck, ensuring optimal contact and screening performance.

Beyond screening, urethane fine plates also find utility in sorting and classification processes within mining operations. Whether separating ores based on size, density, or other characteristics, these plates offer precise and reliable performance. Their smooth surface minimizes material adhesion and blinding, preventing clogging and ensuring uninterrupted operation. This is particularly critical in high-throughput applications where efficiency is paramount.

In addition to their mechanical properties, urethane fine plates offer advantages in terms of customization and versatility. Manufacturers can tailor the plates to meet specific size, shape, and aperture requirements, allowing for seamless integration into diverse mining equipment and processes. Furthermore, advancements in urethane formulation have led to the development of specialty plates with enhanced properties such as increased abrasion resistance or improved flexibility, catering to the evolving needs of the mining industry.

The direct tensioning system employed in urethane deck applications further enhances their performance and longevity. By eliminating the need for traditional fastening methods such as bolts or clips, this system minimizes stress concentrations and potential points of failure. As a result, urethane decks can withstand higher loads and operate at elevated speeds without compromising integrity, thereby maximizing uptime and productivity.

The benefits of urethane fine plates extend beyond operational efficiency to encompass environmental considerations as well. Compared to traditional materials such as steel, urethane offers superior corrosion resistance, reducing the risk of contamination from rust or corrosion products. Additionally, urethane is non-toxic and inert, posing minimal environmental impact throughout its lifecycle. This aligns with the growing emphasis on sustainable practices within the mining industry, further underscoring the relevance of urethane fine plates in modern mining operations.

In conclusion, urethane fine plates play a vital role in enhancing the efficiency, reliability, and sustainability of mining operations. Their exceptional durability, versatility, and performance make them indispensable components in screening, sorting, and classification processes. As the mining industry continues to evolve, the demand for innovative solutions like urethane fine plates is expected to rise, driving further advancements and applications in the field.