Onderzoek naar het productieproces van China’s rubberen trilzeef

Innovaties en vooruitgang in de fabriek voor rubberen zeefgaas in China

Op het gebied van de industriële productie heeft China voortdurend voorop gelopen op het gebied van innovatie en vooruitgang. Eén van die gebieden waarop China aanzienlijke vooruitgang heeft geboekt, is de productie van rubberen trilzeefgaas. Dit product, dat een integraal onderdeel is van verschillende industrieën zoals mijnbouw, steengroeven en recycling, heeft een opmerkelijke evolutie doorgemaakt in het ontwerp- en productieproces, dankzij de niet aflatende inspanningen van Chinese fabrieken voor rubberen zeefgaas.

Inzicht in de kwaliteit en duurzaamheid van China’s rubberen trilgaas

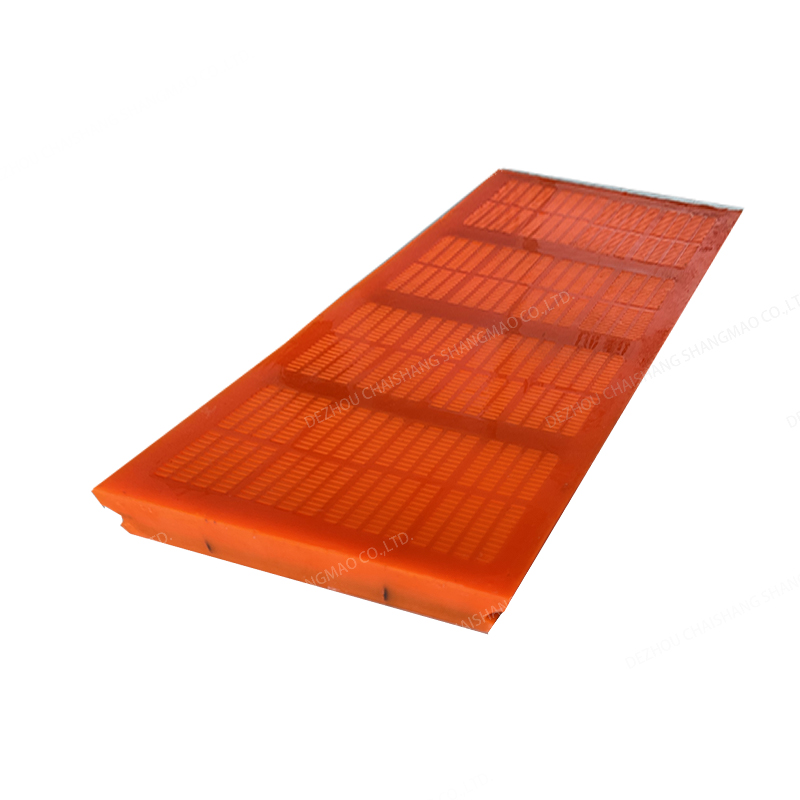

Het begrijpen van de kwaliteit en duurzaamheid van China’s rubberen trilzeefgaas is van cruciaal belang voor industrieën die voor hun activiteiten afhankelijk zijn van deze producten. Als een van ‘s werelds toonaangevende fabrikanten heeft China een reputatie opgebouwd voor het produceren van hoogwaardig rubberen zeefgaas dat voldoet aan de uiteenlopende behoeften van verschillende industrieën. Het rubberen trilzeefgaas is een sleutelcomponent in veel industriële processen, waaronder mijnbouw, steengroeven en recycling. Het is ontworpen om materialen te filteren en te scheiden, zodat alleen de gewenste deeltjes passeren.

De kwaliteit van het Chinese rubberen trilzeefgaas wordt grotendeels toegeschreven aan het nauwgezette productieproces. Het proces begint met de selectie van hoogwaardige rubbermaterialen, die bekend staan om hun duurzaamheid en slijtvastheid. Het rubber wordt vervolgens verwerkt met behulp van geavanceerde technologie om ervoor te zorgen dat het aan de vereiste normen voldoet. Het rubber wordt tot een gaasstructuur gegoten, die vervolgens wordt onderworpen aan een reeks tests om de sterkte en duurzaamheid ervan te verifiëren. Het eindproduct is een rubberen trilzeef dat niet alleen sterk en duurzaam is, maar ook flexibel en bestand tegen corrosie.

Een van de belangrijkste kenmerken van China’s rubberen trilzeef is de hoge treksterkte. Dit is een maatstaf voor hoeveel spanning het gaas kan weerstaan voordat het breekt of vervormt. Hoge treksterkte is cruciaal in industrieën zoals mijnbouw en steengroeven, waar het gaas wordt blootgesteld aan zware belastingen en zware omstandigheden. Het rubberen trilzeefgaas uit China is ontworpen om deze omstandigheden te weerstaan, waardoor een lange levensduur wordt gegarandeerd en de noodzaak voor frequente vervangingen wordt verminderd.

Een ander opvallend kenmerk van het Chinese rubberen trilzeefgaas is het uitstekende trillingsabsorptievermogen. Dit is vooral belangrijk in industrieën waar de machines hoge trillingsniveaus genereren. Het rubberen trilzeef absorbeert deze trillingen, waardoor de impact op de machine wordt verminderd en de levensduur wordt verlengd. Dit verbetert niet alleen de efficiëntie van de machines, maar verlaagt ook de onderhoudskosten.

De duurzaamheid van het Chinese rubberen trilzeefgaas wordt verder verbeterd door de weerstand ervan tegen verschillende omgevingsfactoren. Het rubberen materiaal is bestand tegen water, olie en verschillende chemicaliën, waardoor het geschikt is voor gebruik in een breed scala aan omgevingen. Deze weerstand zorgt er ook voor dat het gaas zijn structurele integriteit in de loop van de tijd behoudt, zelfs als het wordt blootgesteld aan zware omstandigheden.

Naast de kwaliteit en duurzaamheid staat het Chinese rubberen trilgaas ook bekend om zijn veelzijdigheid. Het is verkrijgbaar in verschillende maten en configuraties, waardoor het kan voldoen aan de specifieke behoeften van verschillende industrieën. Of het nu gaat om het filteren van grove materialen in de mijnbouw of fijne deeltjes bij recycling, er is een rubberen trilzeef uit China die aan de eisen voldoet.

Kortom: de kwaliteit en duurzaamheid van China’s rubberen trilzeef zijn een bewijs van de geavanceerde productie van het land mogelijkheden. Het zorgvuldige productieproces, de hoge treksterkte, het uitstekende trillingsabsorptievermogen en de weerstand tegen omgevingsfactoren dragen allemaal bij aan de superieure prestaties van deze producten. Of u zich nu in de mijnbouw, steengroeven, recycling of een andere sector bevindt die filter- en scheidingsmaterialen vereist, u kunt vertrouwen op China’s rubberen trilzeefgaas voor efficiënte en betrouwbare prestaties.

Furthermore, Chinese manufacturers have also made significant strides in environmental sustainability. Recognizing the environmental impact of rubber production, these factories have implemented measures to reduce waste and promote recycling. This commitment to sustainability not only benefits the environment but also contributes to the overall efficiency and cost-effectiveness of the production process.

The advancements in the Chinese rubber screen mesh industry have had far-reaching implications. Industries worldwide now have access to high-quality, durable, and customizable screen meshes that can withstand the toughest conditions. This has led to increased productivity and efficiency, ultimately contributing to the growth and profitability of these industries.

In conclusion, the innovations and advancements in the rubber screen mesh industry in China are a testament to the country’s commitment to industrial excellence. Through the use of new materials, advanced technologies, and sustainable practices, Chinese rubber screen mesh factories have set a new standard in the industry. As they continue to innovate and push the boundaries of what is possible, we can expect to see even more exciting developments in the future. The world will be watching with keen interest as China continues to lead the way in this vital industrial sector.

Understanding the Quality and Durability of China’s rubber vibrating screen Mesh

Understanding the quality and durability of China’s rubber VIBRATING SCREEN MESH is crucial for industries that rely on these products for their operations. As one of the world’s leading manufacturers, China has established a reputation for producing high-quality rubber screen mesh that meets the diverse needs of various industries. The rubber vibrating screen mesh is a key component in many industrial processes, including mining, quarrying, and recycling. It is designed to filter and separate materials, ensuring that only the desired particles pass through.

The quality of China’s rubber vibrating screen mesh is largely attributed to the meticulous manufacturing process. The process begins with the selection of high-quality rubber materials, which are known for their durability and resistance to wear and tear. The rubber is then processed using advanced technology to ensure it meets the required standards. The rubber is molded into a mesh structure, which is then subjected to a series of tests to verify its strength and durability. The end product is a rubber vibrating screen mesh that is not only strong and durable but also flexible and resistant to corrosion.

One of the key features of China’s rubber vibrating screen mesh is its high tensile strength. This is a measure of how much stress the mesh can withstand before it breaks or deforms. High tensile strength is crucial in industries such as mining and quarrying, where the mesh is subjected to heavy loads and harsh conditions. The rubber vibrating screen mesh from China is designed to withstand these conditions, ensuring a long service life and reducing the need for frequent replacements.

Another notable feature of China’s rubber vibrating screen mesh is its excellent vibration absorption ability. This is particularly important in industries where the machinery generates high levels of vibration. The rubber vibrating screen mesh absorbs these vibrations, reducing the impact on the machinery and increasing its lifespan. This not only improves the efficiency of the machinery but also reduces maintenance costs.

The durability of China’s rubber vibrating screen mesh is further enhanced by its resistance to various environmental factors. The rubber material is resistant to water, oil, and various chemicals, making it suitable for use in a wide range of environments. This resistance also ensures that the mesh maintains its structural integrity over time, even when exposed to harsh conditions.

In addition to its quality and durability, China’s rubber vibrating screen mesh is also known for its versatility. It is available in various sizes and configurations, allowing it to meet the specific needs of different industries. Whether it’s for filtering coarse materials in mining or fine particles in recycling, there’s a rubber vibrating screen mesh from China that fits the bill.

In conclusion, the quality and durability of China’s rubber vibrating screen mesh are a testament to the country’s advanced manufacturing capabilities. The meticulous manufacturing process, high tensile strength, excellent vibration absorption ability, and resistance to environmental factors all contribute to the superior performance of these products. Whether you’re in mining, quarrying, recycling, or any other industry that requires filtering and separating materials, you can rely on China’s rubber vibrating screen mesh for efficient and reliable performance.