Innovations in China mesh screen manufacturing: Trends and Technologies

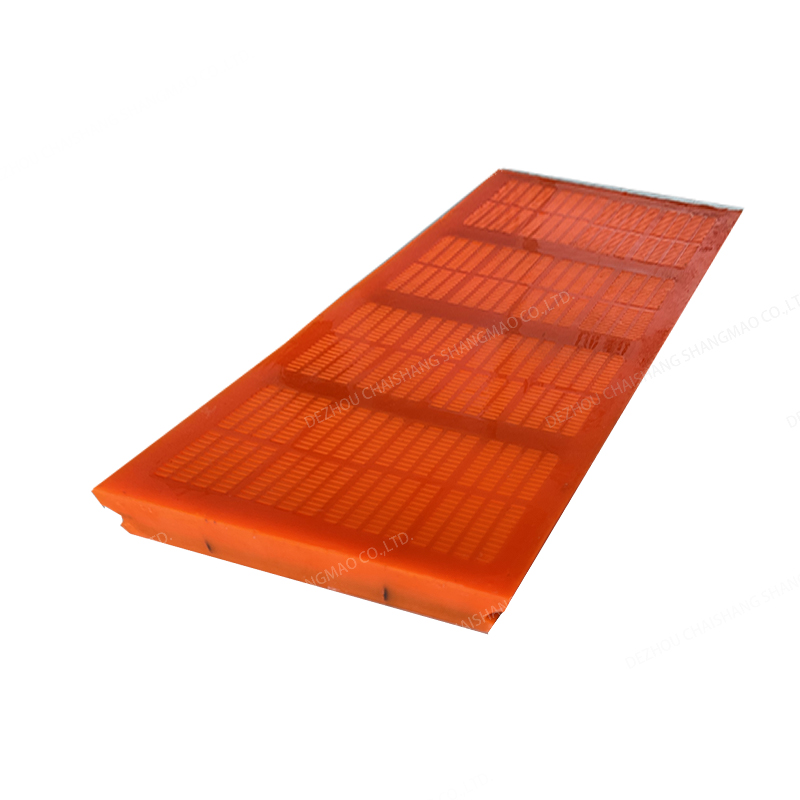

Innovations in China mesh screen Manufacturing: Trends and Technologies The landscape of manufacturing in China has been undergoing a significant transformation, particularly in the realm of mesh screen production. This sector, vital for various applications ranging from industrial filtering to architectural design, has seen a surge in technological advancements and trends that are setting new standards globally. As the world’s leading hub for manufacturing, China’s mesh screen and vibrating screen MESH manufacturers are at the forefront of this innovation wave, leveraging cutting-edge technologies to meet the evolving demands of both domestic and international markets. One of the most notable trends in this sector is the increasing adoption of automation and precision engineering. Chinese manufacturers are integrating sophisticated machinery and computer-aided design (CAD) software into their production lines, enabling them to produce mesh screens with unparalleled accuracy and consistency. This shift towards automation not only enhances the quality of the final product but also significantly boosts production efficiency, allowing manufacturers to cater to large orders with tight deadlines.

Moreover, the focus on sustainability and eco-friendly production processes has become a priority for mesh screen manufacturers in China. In response to growing environmental concerns and stricter regulations, many companies are exploring innovative materials and manufacturing techniques that minimize waste and reduce carbon footprints. For instance, the use of recycled materials in the production of vibrating screen mesh is gaining traction, offering a greener alternative without compromising on durability or performance.

Another exciting development in this field is the exploration of new materials and coatings that enhance the functionality of mesh screens. Manufacturers are experimenting with nanotechnology and advanced polymers to create screens that are not only stronger and more resilient but also possess unique properties such as antimicrobial resistance or self-cleaning capabilities. These advancements open up new possibilities for the application of mesh screens in sectors like healthcare, food processing, and even consumer electronics, where hygiene and maintenance are critical concerns.

The integration of smart technologies into mesh screens is also a trend that is rapidly gaining momentum. With the advent of the Internet of Things (IoT), manufacturers are embedding sensors and connectivity features into their products, transforming traditional screens into intelligent devices. These smart mesh screens can monitor their condition in real-time, predict maintenance needs, and even adjust their properties dynamically to optimize performance. This innovation not only enhances the user experience but also extends the lifespan of the screens, offering significant cost savings over time.

In conclusion, the mesh screen manufacturing industry in China is experiencing a period of dynamic change, driven by technological innovations and shifting market demands. From automation and sustainability to the exploration of new materials and the integration of smart technologies, Chinese manufacturers are leading the way in redefining what is possible in this field. As these trends continue to evolve, it is clear that the future of mesh screen manufacturing will be characterized by increased efficiency, environmental responsibility, and the creation of products that offer unprecedented levels of performance and versatility.

One of the most notable trends in this sector is the increasing adoption of automation and precision engineering. Chinese manufacturers are integrating sophisticated machinery and computer-aided design (CAD) software into their production lines, enabling them to produce mesh screens with unparalleled accuracy and consistency. This shift towards automation not only enhances the quality of the final product but also significantly boosts production efficiency, allowing manufacturers to cater to large orders with tight deadlines.

Moreover, the focus on sustainability and eco-friendly production processes has become a priority for mesh screen manufacturers in China. In response to growing environmental concerns and stricter regulations, many companies are exploring innovative materials and manufacturing techniques that minimize waste and reduce carbon footprints. For instance, the use of recycled materials in the production of vibrating screen mesh is gaining traction, offering a greener alternative without compromising on durability or performance.

Another exciting development in this field is the exploration of new materials and coatings that enhance the functionality of mesh screens. Manufacturers are experimenting with nanotechnology and advanced polymers to create screens that are not only stronger and more resilient but also possess unique properties such as antimicrobial resistance or self-cleaning capabilities. These advancements open up new possibilities for the application of mesh screens in sectors like healthcare, food processing, and even consumer electronics, where hygiene and maintenance are critical concerns.

The integration of smart technologies into mesh screens is also a trend that is rapidly gaining momentum. With the advent of the Internet of Things (IoT), manufacturers are embedding sensors and connectivity features into their products, transforming traditional screens into intelligent devices. These smart mesh screens can monitor their condition in real-time, predict maintenance needs, and even adjust their properties dynamically to optimize performance. This innovation not only enhances the user experience but also extends the lifespan of the screens, offering significant cost savings over time.

In conclusion, the mesh screen manufacturing industry in China is experiencing a period of dynamic change, driven by technological innovations and shifting market demands. From automation and sustainability to the exploration of new materials and the integration of smart technologies, Chinese manufacturers are leading the way in redefining what is possible in this field. As these trends continue to evolve, it is clear that the future of mesh screen manufacturing will be characterized by increased efficiency, environmental responsibility, and the creation of products that offer unprecedented levels of performance and versatility.

Comparing Vibrating Screen Mesh Providers: A Guide to China’s Manufacturers

In the realm of industrial machinery, the vibrating screen mesh plays a pivotal role in various sectors, including mining, agriculture, pharmaceuticals, and construction. This essential component is designed to filter, separate, and size different materials, ensuring efficiency and precision in production processes. China, as a global manufacturing hub, boasts a plethora of manufacturers specializing in the production of high-quality vibrating screen mesh. This article aims to guide businesses and individuals through the process of comparing these providers, shedding light on the factors that set apart the best in the field. The journey to selecting the right vibrating screen mesh manufacturer begins with understanding the diversity of options available within China’s vast industrial landscape. The country’s manufacturers range from large-scale enterprises with extensive international networks to smaller, specialized firms that focus on niche markets. Each of these manufacturers brings a unique set of strengths, technological capabilities, and customer service approaches to the table. Therefore, identifying one’s specific needs and requirements is the first step in narrowing down the list of potential suppliers. Quality stands as the paramount consideration when comparing vibrating screen mesh providers. The durability, efficiency, and precision of the mesh directly impact the overall performance of the screening equipment. Chinese manufacturers have made significant strides in adopting advanced manufacturing technologies and quality control systems. Prospective buyers should look for providers that adhere to international quality standards, such as ISO certification, which serves as a testament to their commitment to excellence. Additionally, exploring the materials used in the production of the mesh, such as high-tensile steel or stainless steel, provides insights into its longevity and suitability for specific applications. Another critical aspect to consider is the level of customization offered by the manufacturer. Given the diverse applications of vibrating screen mesh, the ability to tailor products to meet specific operational requirements is invaluable. Leading manufacturers in China are equipped to offer custom solutions, ranging from varying mesh sizes and shapes to specialized coatings that enhance performance in challenging environments. Engaging with providers that demonstrate a willingness to understand and adapt to unique customer needs signifies a partnership approach, which is crucial for achieving optimal results. Technological innovation is a key differentiator among vibrating screen mesh manufacturers. The best providers stay at the forefront of industry advancements, incorporating cutting-edge technologies into their production processes. This not only improves the quality and performance of the mesh but also introduces efficiencies that can lead to cost savings for customers. When comparing manufacturers, it is beneficial to inquire about their research and development efforts, as well as any proprietary technologies or patents they hold. This information can provide a glimpse into their capability to deliver superior products that meet the evolving demands of the market.Lastly, customer service and support are essential factors that influence the decision-making process. Reliable manufacturers offer comprehensive support, from initial consultations and custom design services to after-sales assistance. The availability of technical support, timely delivery, and responsive communication channels are indicators of a manufacturer’s dedication to customer satisfaction. Establishing a strong relationship with a provider that values customer service ensures a smooth and successful collaboration. In conclusion, comparing vibrating screen mesh manufacturers in China requires a thorough evaluation of several key factors, including quality, customization capabilities, technological innovation, and customer service. By carefully assessing these elements, businesses and individuals can make informed decisions, selecting a provider that not only meets but exceeds their specific needs and expectations. With the right partner, the benefits of high-quality vibrating screen mesh can be fully realized, contributing to enhanced efficiency and productivity in various industrial applications.