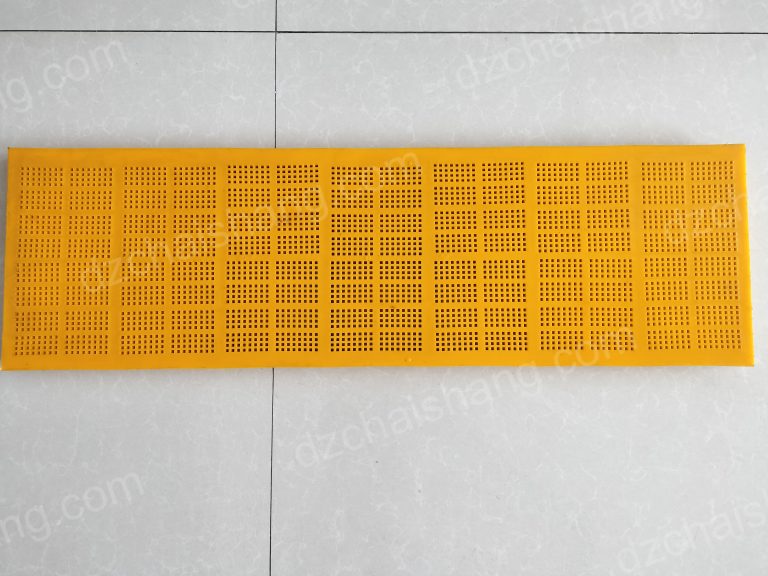

Exploring the Chemical Composition of polyurethane screens: What You Need to Know

Polyurethane screens are a popular choice for many applications, from industrial to residential. They are known for their durability, flexibility, and chemical resistance. But what is the chemical composition of polyurethane screens?

Polyurethane is a polymer made up of two components: a polyol and an isocyanate. The polyol is a long-chain alcohol, usually derived from petroleum, while the isocyanate is a compound containing nitrogen and carbon. When these two components are combined, they form a flexible, durable material that is resistant to many chemicals.

The chemical composition of polyurethane screens can vary depending on the type of polyurethane used. For example, some polyurethanes are made with a polyol and an isocyanate, while others are made with a polyol and a polyisocyanate. The type of polyurethane used will determine the properties of the screen, such as its flexibility, durability, and chemical resistance.

In addition to the polyol and isocyanate, polyurethane screens may also contain other chemicals, such as plasticizers, stabilizers, and colorants. These chemicals can affect the properties of the screen, such as its flexibility, durability, and chemical resistance.

When selecting a polyurethane screen, it is important to consider the chemical composition of the material. Different types of polyurethane will have different properties, so it is important to choose the right type for the application. It is also important to consider the other chemicals that may be present in the material, as these can affect the properties of the screen.

By understanding the chemical composition of polyurethane screens, you can make an informed decision about which type of screen is best for your application. With the right type of polyurethane, you can ensure that your screen is durable, flexible, and resistant to many chemicals.

The Benefits of Polyurethane Screens: Understanding the Chemical Components