High Quality screen mesh Made in China Factory: Exploring the Benefits of polyurethane screens

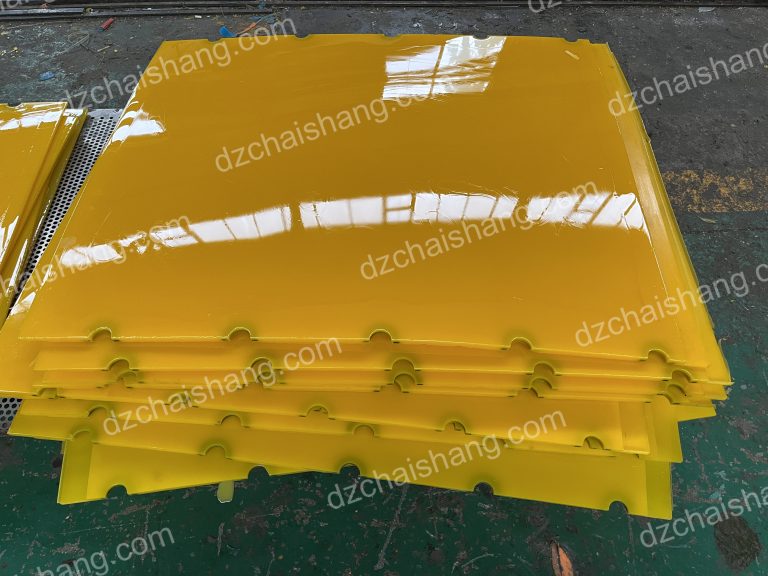

Polyurethane screens, increasingly popular in various industrial applications, offer a superior alternative to traditional screening materials like wire mesh and rubber. Manufactured extensively in China, these screens are lauded for their exceptional durability and efficiency, making them a preferred choice for companies looking to enhance operational effectiveness and reduce downtime. Central to the appeal of polyurethane screens is their remarkable durability. Unlike metal screens, which can suffer from corrosion, or rubber screens, prone to wear and tear, polyurethane is resistant to both abrasion and chemical interactions. This resilience is particularly advantageous in industries such as mining and quarrying, where equipment is regularly exposed to harsh conditions. The robust nature of polyurethane extends the lifespan of the screens significantly, reducing the frequency of replacements and thereby minimizing operational interruptions.

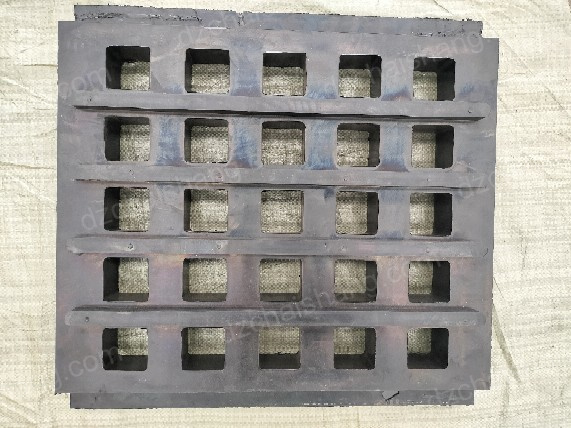

Another pivotal advantage of polyurethane screens is their superior performance in screening applications. These screens are designed with precision to ensure maximum efficiency in separating different materials. The flexibility of polyurethane allows for a more effective vibration of the screen, which in turn enhances the screening process by allowing more material to pass through without clogging. This efficiency is not only beneficial in terms of output quality but also impacts the overall productivity of the screening operation.

Furthermore, the customization options available with polyurethane screens are extensive. Manufacturers in China are capable of producing screens that are tailored to specific industrial needs. This customization ranges from varying levels of hardness to different aperture shapes and sizes, which can be critical in meeting the specific requirements of various screening applications. The ability to customize these screens allows for optimal performance, tailored to unique operational demands, thus enabling industries to achieve more precise screening results.

In addition to functional benefits, polyurethane screens also offer environmental advantages. They are more environmentally friendly compared to traditional materials, as they are generally more durable and need less frequent replacement. This durability translates to less waste and fewer resources used over time. Moreover, polyurethane is often recyclable, adding an element of sustainability that is increasingly valued in global manufacturing practices.

Central to the appeal of polyurethane screens is their remarkable durability. Unlike metal screens, which can suffer from corrosion, or rubber screens, prone to wear and tear, polyurethane is resistant to both abrasion and chemical interactions. This resilience is particularly advantageous in industries such as mining and quarrying, where equipment is regularly exposed to harsh conditions. The robust nature of polyurethane extends the lifespan of the screens significantly, reducing the frequency of replacements and thereby minimizing operational interruptions.

Another pivotal advantage of polyurethane screens is their superior performance in screening applications. These screens are designed with precision to ensure maximum efficiency in separating different materials. The flexibility of polyurethane allows for a more effective vibration of the screen, which in turn enhances the screening process by allowing more material to pass through without clogging. This efficiency is not only beneficial in terms of output quality but also impacts the overall productivity of the screening operation.

Furthermore, the customization options available with polyurethane screens are extensive. Manufacturers in China are capable of producing screens that are tailored to specific industrial needs. This customization ranges from varying levels of hardness to different aperture shapes and sizes, which can be critical in meeting the specific requirements of various screening applications. The ability to customize these screens allows for optimal performance, tailored to unique operational demands, thus enabling industries to achieve more precise screening results.

In addition to functional benefits, polyurethane screens also offer environmental advantages. They are more environmentally friendly compared to traditional materials, as they are generally more durable and need less frequent replacement. This durability translates to less waste and fewer resources used over time. Moreover, polyurethane is often recyclable, adding an element of sustainability that is increasingly valued in global manufacturing practices.The production of high-quality polyurethane screens in China is supported by advanced manufacturing technologies and rigorous quality control processes. Chinese factories are renowned for their capacity to integrate new technological advancements quickly, allowing them to maintain high standards of production efficiency and product quality. The commitment to quality not only ensures the production of superior screens but also bolsters the reliability and reputation of Chinese manufacturing on a global scale. In conclusion, the shift towards polyurethane screens reflects a broader trend in industrial operations towards materials that offer both high performance and cost-efficiency. The advantages of using polyurethane screens—durability, efficiency, customization, and environmental friendliness—make them an invaluable tool in industries that rely heavily on screening processes. As such, polyurethane screens manufactured in China are not only transforming screening practices but are also setting new benchmarks for industrial performance and sustainability.