How polyurethane Stack Sizer Plate Dewatering Can Help Reduce Operating Costs

Operating costs are a major concern for any business, and reducing them is a priority for many. One way to reduce operating costs is to use polyurethane stack sizer plate dewatering. This technology is designed to help reduce the amount of energy and water used in the dewatering process, resulting in lower operating costs.

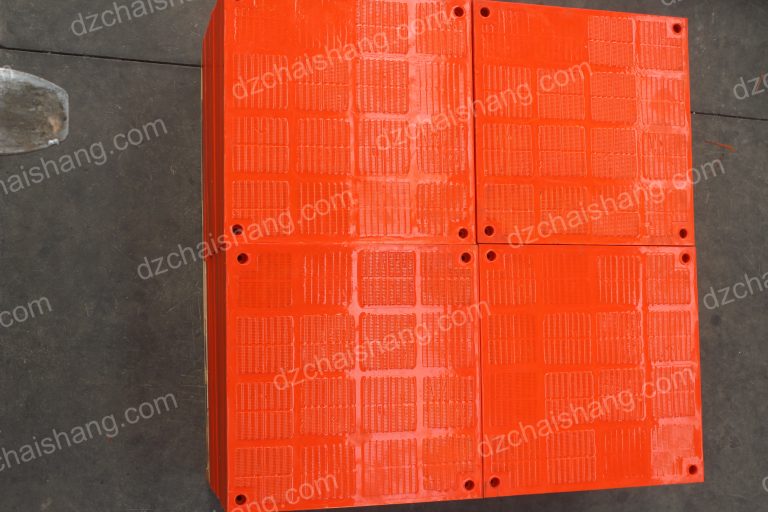

Polyurethane stack sizer plate dewatering is a process that uses a series of plates to separate solids from liquids. The plates are stacked in a vertical configuration and the liquid is forced through the plates. As the liquid passes through the plates, the solids are separated and collected in a container. This process is much more efficient than traditional dewatering methods, as it requires less energy and water to achieve the same results.

The use of polyurethane stack sizer plate dewatering can help reduce operating costs in several ways. First, it reduces the amount of energy and water used in the dewatering process. This can result in lower energy bills and water bills, which can add up over time. Additionally, the process is more efficient than traditional methods, which can lead to faster processing times and improved productivity.

Another benefit of polyurethane stack sizer plate dewatering is that it is a more environmentally friendly option. The process uses less energy and water, which helps to reduce the environmental impact of the dewatering process. Additionally, the process produces less waste, which can help to reduce the amount of waste that needs to be disposed of.

Overall, polyurethane stack sizer plate dewatering is an effective way to reduce operating costs. It is a more efficient and environmentally friendly option than traditional dewatering methods, and it can help to reduce energy and water bills. Additionally, it can lead to faster processing times and improved productivity, which can help to reduce overall costs. If you are looking for a way to reduce your operating costs, polyurethane stack sizer plate dewatering may be the solution you’ve been looking for.

The Benefits of Using a Vibrating urethane trommel screen Producer for Maximum Efficiency

When it comes to industrial processes, efficiency is key. That’s why many companies are turning to vibrating urethane trommel screen producers to help them maximize their efficiency.

Vibrating urethane trommel screen producers are designed to separate materials of different sizes and shapes. This is done by using a vibrating screen that is made of urethane, which is a durable and flexible material. The vibrating screen is designed to move the material along the screen, allowing the material to be separated into different sizes and shapes.

The vibrating urethane trommel screen producers are designed to be highly efficient. They are able to separate materials quickly and accurately, which helps to reduce the amount of time and energy that is needed to complete the process. This helps to reduce the cost of production and increase the efficiency of the process.

The vibrating urethane trommel screen producers are also designed to be easy to use. They are designed to be user-friendly, so that anyone can use them without any difficulty. This makes them ideal for use in industrial processes, as they can be used by anyone regardless of their experience level.

The vibrating urethane trommel screen producers are also designed to be durable. They are designed to withstand the wear and tear of industrial processes, so that they can be used for a long time without needing to be replaced. This helps to reduce the cost of production and increase the efficiency of the process.

Overall, vibrating urethane trommel screen producers are a great way to maximize efficiency in industrial processes. They are designed to be highly efficient, easy to use, and durable, which makes them ideal for use in industrial processes. If you’re looking for a way to increase the efficiency of your industrial process, then consider using a vibrating urethane trommel screen producer.