Benefits of Using Factory Shaker Tension PU screens for Aggregate Screening

Aggregate screening is a crucial process in the construction and mining industries, as it involves separating materials of different sizes to create a uniform product. One of the key components in this process is the tension screen, which is used to classify and separate aggregate materials based on their size. Factory shaker tension PU screens are a popular choice for aggregate screening due to their durability, efficiency, and cost-effectiveness.

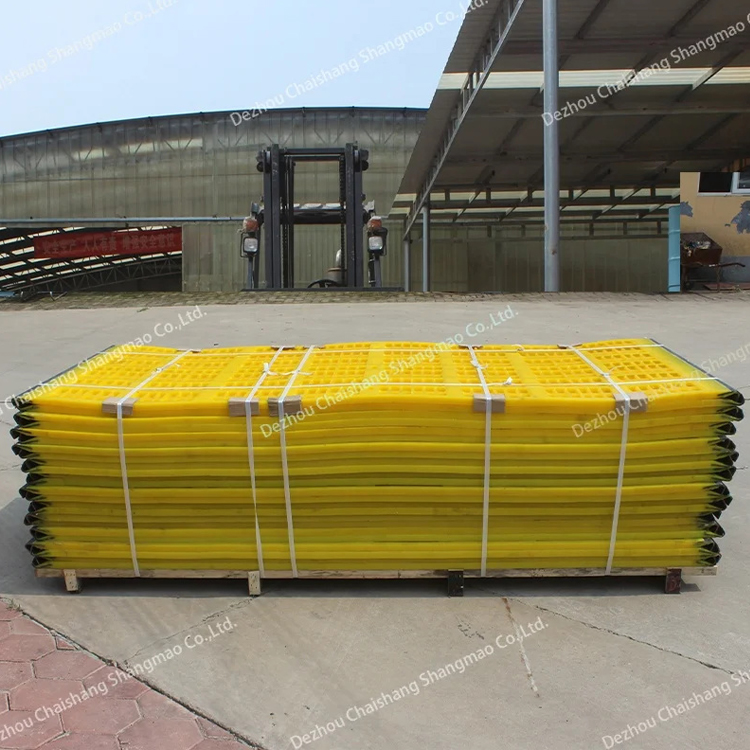

One of the main benefits of using factory shaker tension PU screens is their durability. These screens are made from polyurethane, a material known for its strength and resilience. This means that they can withstand the harsh conditions of the screening process, including high temperatures, abrasive materials, and heavy loads. As a result, factory shaker tension PU screens have a longer lifespan compared to traditional wire mesh screens, reducing the need for frequent replacements and maintenance.

In addition to their durability, factory shaker tension PU screens are also highly efficient in screening aggregate materials. The tensioning system of these screens allows for quick and easy adjustments to the screen tension, ensuring optimal performance and accuracy in classifying materials. This results in a more efficient screening process, with higher throughput and reduced downtime. Furthermore, the high-quality polyurethane material of these screens provides a smooth surface that prevents clogging and blinding, allowing for continuous operation without interruptions.

Another advantage of using factory shaker tension PU screens for aggregate screening is their cost-effectiveness. While the initial investment in these screens may be higher than traditional wire mesh screens, the long-term savings in maintenance and replacement costs make them a more economical choice. The durability and efficiency of factory shaker tension PU screens result in lower operating costs and increased productivity, ultimately leading to a higher return on investment for businesses in the construction and mining industries.

Furthermore, factory shaker tension PU screens offer superior performance in terms of screening accuracy and product quality. The tight tensioning system of these screens ensures that materials are properly classified and separated according to their size, resulting in a uniform product with consistent particle sizes. This is essential for producing high-quality aggregate materials that meet industry standards and specifications. Additionally, the smooth surface of the polyurethane material prevents contamination and impurities from entering the final product, ensuring a clean and reliable end product.

In conclusion, factory shaker tension PU screens are an excellent choice for aggregate screening due to their durability, efficiency, cost-effectiveness, and superior performance. These screens offer a range of benefits that can help businesses in the construction and mining industries improve their screening processes and achieve higher productivity and profitability. By investing in factory shaker tension PU screens, companies can ensure a reliable and efficient screening operation that meets the demands of the industry and delivers high-quality aggregate materials.