Benefits and Applications of Competitive Price polyurethane Tension Panels in Industrial Screening

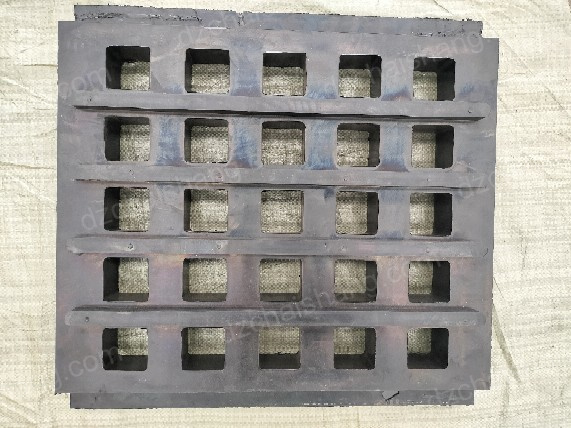

Competitive price polyurethane tension panels, also known as the cheapest linear vibrating PU sieve dewatering screens, are becoming increasingly popular in various industrial applications due to their numerous benefits. These panels are designed to provide efficient and cost-effective solutions for screening and dewatering processes in industries such as mining, quarrying, and recycling. One of the primary advantages of using competitive price polyurethane tension panels is their durability and resistance to wear and tear. Polyurethane is a highly resilient material that can withstand harsh conditions, including exposure to abrasive materials and extreme temperatures. This makes it an ideal choice for industries that require robust and long-lasting screening solutions. Additionally, the flexibility of polyurethane allows these panels to absorb impact and reduce noise levels, which enhances the overall working environment. Another significant benefit of these panels is their ability to improve screening efficiency. The unique design of the linear vibrating PU sieve dewatering screens allows for precise separation of materials based on size and density. This results in a higher quality of the final product, as unwanted particles are effectively removed during the screening process. Furthermore, the panels’ ability to handle high flow rates and large volumes of material makes them suitable for large-scale industrial operations.The cost-effectiveness of competitive price polyurethane tension panels is another key factor that contributes to their widespread use. These panels offer a lower initial investment compared to other screening solutions, such as stainless steel or wire mesh screens. Additionally, the reduced maintenance requirements and longer service life of Polyurethane Panels lead to significant cost savings over time. This makes them an attractive option for businesses looking to optimize their operational expenses. In terms of applications, competitive price polyurethane tension panels are versatile and can be used in a variety of screening and dewatering processes. In the mining industry, for example, these panels are commonly used for the classification of minerals and ores, as well as for dewatering tailings and slurry. In the quarrying industry, they are employed for the separation of aggregates and the removal of fines from crushed stone. The recycling industry also benefits from the use of these panels, as they are effective in sorting and separating recyclable materials such as plastics, metals, and glass. Moreover, the customization options available for competitive price polyurethane tension panels further enhance their suitability for different industrial applications. These panels can be manufactured in various sizes, shapes, and aperture configurations to meet specific screening requirements. This level of customization ensures optimal performance and efficiency in any given application. In conclusion, competitive price polyurethane tension panels offer a range of benefits that make them an ideal choice for industrial screening and dewatering processes. Their durability, efficiency, cost-effectiveness, and versatility are key factors that contribute to their growing popularity in various industries. By choosing these panels, businesses can improve their screening operations, reduce operational costs, and achieve higher quality products, ultimately leading to increased profitability and competitiveness in the market.

Cost-Effective Solutions: Exploring the Cheapest Linear Vibrating PU Sieve Dewatering Systems

In the realm of industrial processes, the need for efficient and cost-effective dewatering solutions is paramount. One such solution that has gained popularity due to its effectiveness and affordability is the Polyurethane (PU) tension panel, specifically designed for linear vibrating sieve systems. This article explores the competitive pricing and advantages of these systems, providing insights into why they are considered among the cheapest and most efficient options available in the market today. Polyurethane tension panels are renowned for their durability and high-performance capabilities. Made from high-quality polyurethane material, these panels are resistant to wear and tear, making them ideal for continuous use in harsh industrial environments. The resilience of polyurethane also ensures that the panels can withstand various types of abrasives and corrosive materials, which are commonly encountered in dewatering processes. This durability translates to lower maintenance costs and longer service life, contributing to the overall cost-effectiveness of the system. The design of the PU tension panel plays a crucial role in its efficiency. The panels are engineered to maximize the screening area, allowing for better separation and faster dewatering. The unique design also promotes optimal vibration, which enhances the sieving process and ensures that solids are effectively separated from liquids. This results in a drier end product, which is essential for many industrial applications such as mineral processing, waste management, and chemical production.

Another advantage of using PU tension panels in linear vibrating sieve systems is their flexibility. These panels can be customized to fit various sieve sizes and shapes, making them versatile for different industrial needs. Whether it’s a small-scale operation or a large-scale production facility, PU tension panels can be tailored to meet specific requirements, ensuring maximum efficiency and productivity.

Cost-wise, PU tension panels offer significant savings compared to other dewatering solutions. Their competitive pricing is primarily due to the cost-effective manufacturing process of polyurethane, which allows for mass production without compromising quality. Additionally, the long service life and minimal maintenance requirements of PU panels reduce the overall operational costs, making them an economical choice for businesses looking to optimize their dewatering processes.

When it comes to installation, PU tension panels are relatively easy to set up and integrate into existing linear vibrating sieve systems. This ease of installation not only saves time but also reduces labor costs, further enhancing the cost-effectiveness of the solution. Moreover, the lightweight nature of polyurethane makes handling and transportation of the panels more manageable, which is an added benefit for companies looking to streamline their operations.

In conclusion, the competitive pricing and numerous advantages of Polyurethane tension panels make them an attractive option for businesses seeking efficient and cost-effective dewatering solutions. Their durability, design efficiency, flexibility, and ease of installation contribute to their popularity in various industrial sectors. By choosing PU tension panels for linear vibrating sieve systems, companies can achieve optimal dewatering performance while keeping operational costs to a minimum. As industries continue to evolve and demand more efficient processes, the role of cost-effective solutions like PU tension panels becomes increasingly important, ensuring sustainability and profitability in the long run.

The design of the PU tension panel plays a crucial role in its efficiency. The panels are engineered to maximize the screening area, allowing for better separation and faster dewatering. The unique design also promotes optimal vibration, which enhances the sieving process and ensures that solids are effectively separated from liquids. This results in a drier end product, which is essential for many industrial applications such as mineral processing, waste management, and chemical production.

Another advantage of using PU tension panels in linear vibrating sieve systems is their flexibility. These panels can be customized to fit various sieve sizes and shapes, making them versatile for different industrial needs. Whether it’s a small-scale operation or a large-scale production facility, PU tension panels can be tailored to meet specific requirements, ensuring maximum efficiency and productivity.

Cost-wise, PU tension panels offer significant savings compared to other dewatering solutions. Their competitive pricing is primarily due to the cost-effective manufacturing process of polyurethane, which allows for mass production without compromising quality. Additionally, the long service life and minimal maintenance requirements of PU panels reduce the overall operational costs, making them an economical choice for businesses looking to optimize their dewatering processes.

When it comes to installation, PU tension panels are relatively easy to set up and integrate into existing linear vibrating sieve systems. This ease of installation not only saves time but also reduces labor costs, further enhancing the cost-effectiveness of the solution. Moreover, the lightweight nature of polyurethane makes handling and transportation of the panels more manageable, which is an added benefit for companies looking to streamline their operations.

In conclusion, the competitive pricing and numerous advantages of Polyurethane tension panels make them an attractive option for businesses seeking efficient and cost-effective dewatering solutions. Their durability, design efficiency, flexibility, and ease of installation contribute to their popularity in various industrial sectors. By choosing PU tension panels for linear vibrating sieve systems, companies can achieve optimal dewatering performance while keeping operational costs to a minimum. As industries continue to evolve and demand more efficient processes, the role of cost-effective solutions like PU tension panels becomes increasingly important, ensuring sustainability and profitability in the long run.