Exploring the Importance of High Quality Sieve and Grading mesh in Crushing screen Meshes

The importance of high-quality sieve and grading mesh in crushing screen meshes cannot be overstated. These components play a pivotal role in various industries, including mining, quarrying, and construction, where they are used to separate, sort, and grade materials. The quality of these meshes directly impacts the efficiency and effectiveness of these processes, making it crucial to understand their significance.

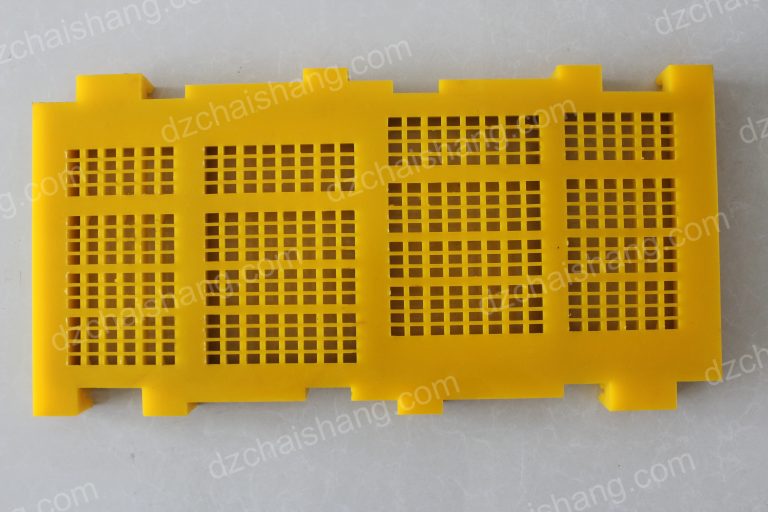

A sieve, in its most basic form, is a tool that separates wanted elements from unwanted material using a mesh. The mesh, with its network of woven or welded wires, allows smaller particles to pass through while larger particles are retained. The grading mesh, on the other hand, is used to categorize particles into different sizes. The precision and accuracy of these processes are largely dependent on the quality of the sieve and grading mesh used.

High-quality sieve and grading meshes are characterized by their durability, precision, and resistance to wear and tear. They are typically made from robust materials such as stainless steel, which can withstand the rigors of heavy-duty industrial processes. The mesh’s wire diameter, aperture size, and weave type are meticulously designed to ensure optimal performance.

The durability of a sieve and grading mesh is paramount in industries such as mining and quarrying, where they are subjected to harsh conditions and abrasive materials. High-quality meshes are resistant to corrosion, wear, and tear, ensuring they maintain their structural integrity over time. This durability translates into reduced maintenance costs and downtime, enhancing the overall efficiency of the operation.

Precision is another critical aspect of high-quality sieve and grading meshes. The accuracy of the separation and grading processes hinges on the precise sizing of the mesh apertures. High-quality meshes are manufactured with strict adherence to size specifications, ensuring that the desired particle size distribution is achieved. This precision is crucial in industries such as construction, where the grading of aggregates directly impacts the quality of the final product.

Resistance to wear and tear is a defining feature of high-quality sieve and grading meshes. In the crushing process, the mesh is subjected to constant friction and impact from the materials being processed. High-quality meshes are designed to withstand these conditions, maintaining their performance over extended periods. This resistance to wear and tear not only prolongs the lifespan of the mesh but also ensures consistent output quality.

In conclusion, the importance of high-quality sieve and grading mesh in crushing screen meshes is evident. Their durability, precision, and resistance to wear and tear make them indispensable in various industrial processes. By investing in high-quality sieve and grading meshes, industries can enhance their operational efficiency, reduce maintenance costs, and ensure the quality of their output. Therefore, when it comes to sieve and grading meshes, quality should never be compromised.

Understanding the Role of High Quality Sieve and Grading Mesh in Enhancing Crushing Screen Meshes Efficiency

High-quality sieve and grading mesh play a pivotal role in enhancing the efficiency of crushing screen meshes. These components are integral to various industries, including mining, quarrying, and construction, where they are used to separate, sort, and grade materials. The quality of these meshes significantly influences the overall performance and productivity of the crushing process, making it essential to understand their role and importance.

A sieve, in its most basic form, is a tool that separates wanted elements from unwanted material using a woven wire or a Perforated Plate. The quality of a sieve is determined by its ability to accurately perform this separation process. High-quality sieves are characterized by their durability, precision, and resistance to wear and tear. They are designed to withstand the rigors of heavy-duty operations, ensuring a consistent and reliable performance over time.

On the other hand, a grading mesh is used to classify materials based on their size. It separates particles into different grades, allowing for a more efficient and effective crushing process. A high-quality grading mesh is distinguished by its precision and consistency in sorting materials. It ensures that the particles are evenly distributed, which in turn, enhances the efficiency of the crushing screen meshes.

The crushing screen meshes are the final component in this process. They are responsible for the actual crushing of the material. The efficiency of these meshes is directly influenced by the quality of the sieves and grading meshes used. High-quality sieve and grading mesh ensure that the material fed into the crushing screen meshes is of the right size and consistency. This reduces the likelihood of blockages and the need for re-crushing, thereby improving the overall efficiency of the process.

Moreover, high-quality sieve and grading mesh are designed to handle a wide range of materials, from coarse rocks to fine sand. This versatility allows them to be used in various applications, further enhancing their efficiency. They also contribute to the longevity of the crushing screen meshes. By ensuring that only appropriately sized material is processed, they reduce the wear and tear on the crushing screen meshes, extending their lifespan and reducing maintenance costs.

In addition to their functional benefits, high-quality sieve and grading mesh also offer economic advantages. By improving the efficiency of the crushing process, they help to increase productivity and reduce operational costs. They also minimize waste, as they ensure that all material is processed correctly the first time around. This not only saves resources but also reduces the environmental impact of the operation.

In conclusion, high-quality sieve and grading mesh are essential components in enhancing the efficiency of crushing screen meshes. They play a crucial role in the separation, sorting, and grading of materials, ensuring that the crushing process is as efficient and effective as possible. By investing in high-quality sieve and grading mesh, industries can improve their productivity, reduce operational costs, and minimize their environmental impact. Therefore, understanding the role and importance of these components is key to maximizing the efficiency of crushing screen meshes.