Understanding the Role of high frequency screens in Sand Vibrating Processes

High frequency screens play a crucial role in the sand vibrating processes used in various industries, including mining, construction, and mineral processing. These screens, often referred to as ‘vibrating screens,’ are instrumental in the separation and classification of different particle sizes. They are designed to vibrate at high frequencies, which increases the speed of the material flow and enhances the efficiency of the screening process.

The high frequency screen operates by vibrating the screen mesh at a rate that is much faster than a typical vibrating screen. This rapid vibration breaks down the surface tension between the particles, allowing smaller particles to fall through the mesh while larger particles remain on top. The result is a highly efficient separation process that can handle large volumes of material in a relatively short period.

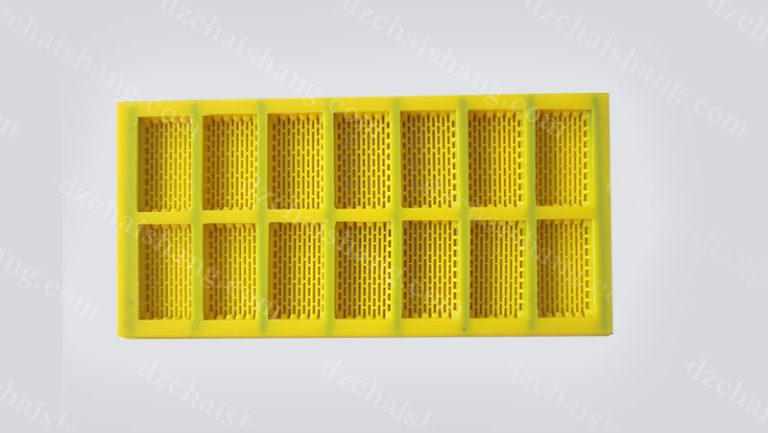

The screen mesh is a critical component of the high frequency screen. It is the medium through which the material passes, and its size and shape determine the size of the particles that can pass through. The mesh is typically made of metal or synthetic materials that can withstand the high frequency vibrations without tearing or deforming. The size of the mesh openings, or ‘apertures,’ can be adjusted to control the size of the particles that pass through. This allows for a high degree of customization, enabling operators to fine-tune the screening process to meet specific requirements.

The use of high frequency screens in sand vibrating processes offers several advantages. First, they provide a high level of efficiency, allowing for the rapid processing of large volumes of material. This is particularly beneficial in industries such as mining and construction, where time is often a critical factor. Second, the high frequency vibrations break down the surface tension between particles, which can improve the separation of fine particles that might otherwise stick together. This can result in a higher quality end product. Finally, the ability to adjust the size of the mesh apertures allows for a high degree of control over the screening process, enabling operators to meet specific size requirements.

However, it’s important to note that while high frequency screens offer many benefits, they also have some limitations. For instance, they can be more susceptible to wear and tear due to the high frequency vibrations. This can lead to increased maintenance requirements and potentially higher operating costs. Additionally, while the ability to adjust the mesh size provides flexibility, it also requires a certain level of expertise to ensure that the correct size is chosen for a given application.

In conclusion, high frequency screens play a pivotal role in sand vibrating processes. They provide a highly efficient means of separating and classifying different particle sizes, thanks to their rapid vibration rates and adjustable mesh apertures. While they do have some limitations, their benefits often outweigh these drawbacks, making them a valuable tool in many industries. As technology continues to advance, it’s likely that we’ll see further improvements in high frequency screen design and operation, leading to even greater efficiency and versatility in the future.

Exploring the Impact of Mesh Size on the Efficiency of screen vibrating sand

High frequency screens, mesh, and screen vibrating sand are integral components in the mining and construction industries. These tools play a crucial role in the separation and classification of materials, particularly in the sand and gravel industry. The efficiency of these tools is largely dependent on the mesh size, which significantly impacts the quality of the output. This article explores the impact of mesh size on the efficiency of screen vibrating sand.

High frequency screens are designed to operate at a frequency higher than the vibrations of the human body. This allows the screens to separate materials based on size, shape, and density. The screens are typically made of a mesh material, which is a network of interconnected wires or threads. The size of the openings in the mesh, known as the mesh size, determines the size of the particles that can pass through the screen.

The mesh size is a critical factor in the efficiency of screen vibrating sand. The size of the mesh openings directly affects the quality and consistency of the output. A smaller mesh size will allow only finer particles to pass through, resulting in a more uniform and high-quality output. Conversely, a larger mesh size will allow larger particles to pass through, which may result in a less uniform output.

However, while a smaller mesh size may produce a higher quality output, it may also reduce the efficiency of the screen vibrating sand. This is because smaller mesh sizes can become clogged more easily, reducing the flow of material through the screen. This can lead to a decrease in productivity and an increase in maintenance requirements. Therefore, it is essential to strike a balance between the quality of the output and the efficiency of the screen.

The choice of mesh size also depends on the specific requirements of the project. For instance, if the project requires a high degree of precision and uniformity, a smaller mesh size may be appropriate. On the other hand, if the project requires a high throughput rate, a larger mesh size may be more suitable.

In addition to the mesh size, other factors can also affect the efficiency of screen vibrating sand. These include the moisture content of the material, the angle of the screen, and the speed of the vibrations. By optimizing these factors in conjunction with the mesh size, it is possible to maximize the efficiency of the screen vibrating sand.

In conclusion, the mesh size plays a pivotal role in the efficiency of screen vibrating sand. It directly impacts the quality and consistency of the output, as well as the productivity and maintenance requirements of the screen. Therefore, it is crucial to carefully consider the mesh size when designing and operating a high frequency screen. By doing so, it is possible to achieve a balance between the quality of the output and the efficiency of the screen, thereby maximizing the overall performance of the screen vibrating sand.