Wear and Tear

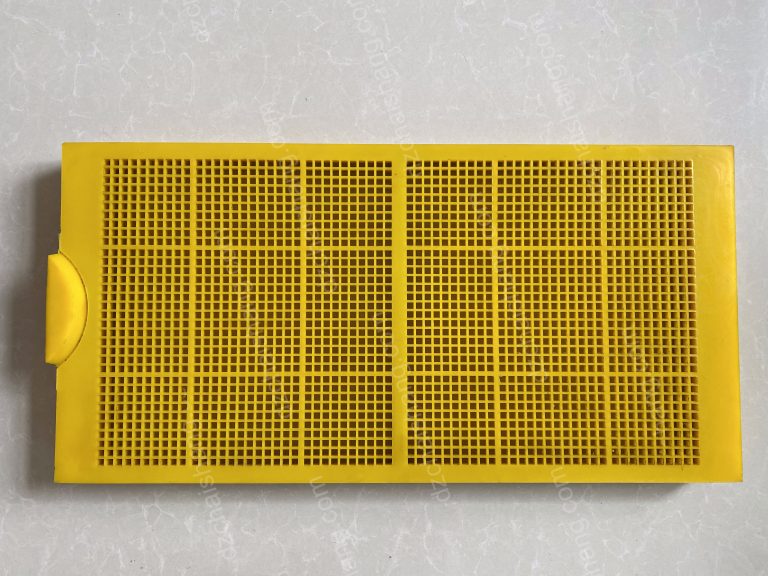

polyurethane screens are widely used in various industries for screening and separating materials. These screens are known for their durability, flexibility, and resistance to abrasion, making them a popular choice for many applications. However, like any other equipment, polyurethane screens are also subject to wear and tear over time. There are three major factors that can affect the life of polyurethane screens: material properties, operating conditions, and maintenance practices.

The material properties of polyurethane screens play a crucial role in determining their lifespan. Polyurethane is a versatile material that can be customized to meet specific requirements. The hardness, elasticity, and chemical resistance of polyurethane can vary depending on the formulation used. Screens made from high-quality polyurethane with the right properties are more likely to withstand wear and tear for a longer period. On the other hand, screens made from low-quality or improperly formulated polyurethane may degrade quickly, leading to premature failure.

Operating conditions also have a significant impact on the life of polyurethane screens. Factors such as the type of material being screened, the size of the particles, the frequency of use, and the speed of operation can all affect the wear and tear on the screens. For example, abrasive materials or high-impact applications can cause faster degradation of the screen surface. Similarly, operating the screens at higher speeds or under extreme temperatures can also accelerate wear and tear. It is essential to consider these factors when selecting polyurethane screens for a specific application to ensure optimal performance and longevity.

Proper maintenance practices are essential for extending the life of polyurethane screens. Regular inspection, cleaning, and maintenance can help identify any signs of wear or damage early on and prevent further deterioration. Cleaning the screens regularly with the appropriate cleaning agents can help remove any buildup of material or contaminants that can cause premature wear. Inspecting the screens for any signs of wear, such as tears, holes, or deformation, can help identify potential issues before they escalate. Additionally, following the manufacturer’s guidelines for installation, operation, and maintenance can help maximize the lifespan of polyurethane screens.

In conclusion, the life of polyurethane screens is influenced by various factors, including material properties, operating conditions, and maintenance practices. Choosing high-quality polyurethane with the right properties, considering the operating conditions, and implementing proper maintenance practices are essential for ensuring the longevity of polyurethane screens. By understanding these factors and taking proactive measures to address them, industries can maximize the performance and lifespan of polyurethane screens, ultimately reducing downtime and maintenance costs. Polyurethane screens are a valuable investment that can provide long-lasting and reliable screening solutions when properly cared for and maintained.