Exploring the Benefits of Using Price Vibrator PU Trommel mesh in Industrial Applications

Exploring the Benefits of Using Price Vibrator PU Trommel Mesh in Industrial Applications

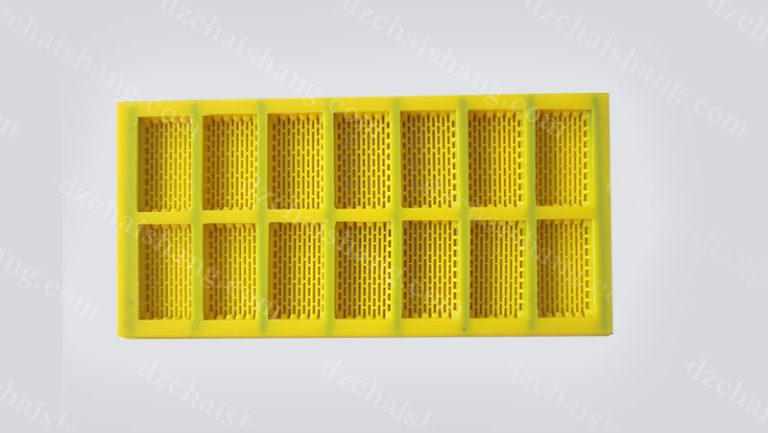

Industrial applications often require robust materials capable of withstanding harsh conditions while maintaining efficiency. In this regard, Price Vibrator PU Trommel Mesh emerges as a valuable solution offering durability, versatility, and enhanced performance across various industries. Understanding its benefits illuminates its significance in optimizing industrial processes.

Price Vibrator PU Trommel Mesh, crafted from polyurethane (PU), stands out for its exceptional resilience and longevity. Unlike traditional materials, such as steel or rubber, PU mesh exhibits superior resistance to abrasion, corrosion, and impact, making it ideal for demanding environments. This durability ensures prolonged operational lifespan, reducing the frequency of replacements and associated downtime, thereby enhancing productivity.

Moreover, Price Vibrator PU Trommel Mesh offers versatility in application, catering to diverse industrial requirements. Its flexibility enables customization to specific dimensions and configurations, accommodating various machinery and processes. Whether used in mining, aggregates, recycling, or chemical industries, PU mesh adapts seamlessly, contributing to the seamless functioning of equipment and systems.

One notable advantage of Price Vibrator PU Trommel Mesh lies in its vibration-enhancing properties. The inherent flexibility of PU material facilitates efficient transmission of vibration, essential for effective screening and separation processes. This feature ensures thorough material classification, improving overall productivity and product quality. Additionally, vibration aids in preventing clogging and blinding, optimizing operational efficiency.

Furthermore, Price Vibrator PU Trommel Mesh offers significant energy savings compared to conventional alternatives. Its lightweight nature reduces the energy required for operation, resulting in lower power consumption and decreased operational costs. This efficiency not only enhances economic viability but also aligns with sustainable practices, reducing carbon footprint and environmental impact.

In industrial settings where hygiene and cleanliness are paramount, Price Vibrator PU Trommel Mesh excels due to its non-porous surface and ease of cleaning. Unlike porous materials prone to bacterial growth and contamination, PU mesh maintains hygiene standards, ensuring product purity and compliance with regulatory requirements. Its smooth surface facilitates effortless cleaning, minimizing downtime and maximizing operational uptime.

Moreover, Price Vibrator PU Trommel Mesh contributes to a quieter working environment, mitigating noise pollution associated with industrial operations. The damping properties of PU material attenuate noise generated during screening and sieving processes, creating a more conducive workplace. This reduction in noise levels not only enhances employee comfort and safety but also fosters a more harmonious relationship with surrounding communities.

In addition to its tangible benefits, Price Vibrator PU Trommel Mesh offers cost-effective solutions for industrial operations. While the initial investment may be slightly higher than traditional materials, the long-term savings in maintenance, replacement, and energy costs far outweigh the initial expenditure. This cost efficiency, coupled with enhanced performance and durability, positions PU mesh as a prudent investment for businesses seeking sustainable growth.

In conclusion, Price Vibrator PU Trommel Mesh emerges as a valuable asset in industrial applications, offering a myriad of benefits ranging from durability and versatility to efficiency and cost-effectiveness. Its superior performance, coupled with vibration-enhancing properties, contributes to enhanced productivity, product quality, and operational efficiency. As industries strive for innovation and optimization, PU mesh stands as a testament to progress, providing reliable solutions for evolving industrial needs.

How to Choose the Right Trommel PU Mesh Maker for Your Specific Requirements

When it comes to selecting the right trommel PU mesh maker for your specific requirements, there are several key factors to consider. Trommel screens are vital components in various industries, including mining, construction, and recycling, as they efficiently separate materials by size. The quality and performance of the trommel PU mesh play a crucial role in the effectiveness of the screening process. In this article, we’ll explore the considerations you should keep in mind when choosing a trommel PU mesh maker.

First and foremost, it’s essential to assess the quality of the materials used by the mesh maker. High-quality polyurethane (PU) is durable, abrasion-resistant, and offers excellent elasticity, ensuring longevity and efficient screening operations. A reputable mesh maker will use premium-grade pu materials that can withstand the rigors of continuous use in demanding environments.

In addition to material quality, consider the manufacturing process employed by the mesh maker. Advanced manufacturing techniques, such as injection molding or compression molding, can result in precise and uniform trommel PU meshes. These meshes offer consistent performance and durability, contributing to the overall efficiency of the screening process.

Furthermore, take into account the expertise and experience of the mesh maker. A company with a proven track record in producing high-quality trommel PU meshes is more likely to meet your specific requirements and provide reliable products. Look for manufacturers with extensive industry experience and a reputation for delivering superior products and customer service.

Another crucial aspect to consider is customization options. Every screening application is unique, and having the ability to customize the trommel PU mesh to suit your specific requirements can significantly enhance its effectiveness. Choose a mesh maker that offers customization options in terms of mesh size, aperture shape, and overall dimensions to ensure optimal performance in your application.

Additionally, consider the availability of technical support and after-sales service. A reliable mesh maker will provide comprehensive technical support to assist you with installation, operation, and maintenance of the trommel PU mesh. Moreover, prompt and efficient after-sales service ensures that any issues or concerns are addressed promptly, minimizing downtime and maximizing productivity.

Cost is also a factor to consider when choosing a trommel PU mesh maker. While it’s essential to stick to your budget, prioritize quality and performance over upfront cost savings. Investing in a high-quality trommel PU mesh from a reputable manufacturer may initially cost more but can save you money in the long run by minimizing downtime, reducing maintenance costs, and improving overall efficiency.

In conclusion, selecting the right trommel PU mesh maker requires careful consideration of various factors, including material quality, manufacturing process, expertise, customization options, technical support, and cost. By evaluating these factors and choosing a reputable manufacturer that meets your specific requirements, you can ensure optimal performance and durability of your trommel PU mesh, ultimately enhancing the efficiency of your screening operations.