Exploring the Efficiency of pu sieve panels in Coal Processing

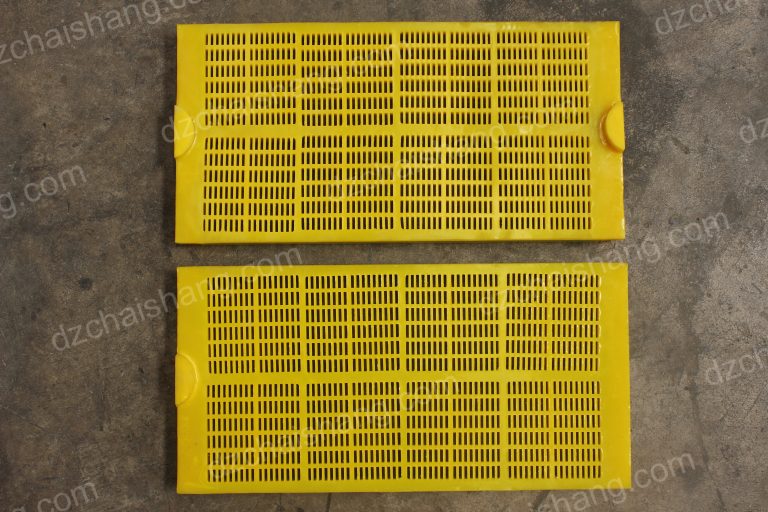

PU sieve panels, also known as polyurethane sieve panels, are an integral part of the coal processing industry. These panels are designed to provide a high level of efficiency and durability, making them an ideal choice for coal processing plants. The use of PU sieve panels in coal processing has revolutionized the industry, offering numerous benefits that have significantly improved the overall process.

PU sieve panels are made from a material known as polyurethane, which is renowned for its exceptional durability and resistance to wear and tear. This makes it an excellent choice for use in environments where it will be subjected to heavy use and harsh conditions, such as coal processing plants. The durability of PU sieve panels ensures that they can withstand the rigors of coal processing, reducing the need for frequent replacements and thereby saving on costs.

In addition to their durability, PU sieve panels also offer a high level of efficiency. They are designed to effectively separate different sizes of coal particles, ensuring that only the desired size is processed further. This not only improves the quality of the coal produced but also enhances the overall efficiency of the coal processing plant. The use of PU sieve panels can therefore lead to significant cost savings, as it reduces the amount of coal that is wasted during the processing stage.

Another key advantage of PU sieve panels is their flexibility. Unlike other types of sieve panels, PU sieve panels can be customized to meet the specific needs of a coal processing plant. This means that they can be designed to handle different sizes of coal particles, depending on the requirements of the plant. This level of customization can greatly enhance the efficiency of the coal processing process, as it ensures that the sieve panels are perfectly suited to the task at hand.

Furthermore, PU sieve panels are also easy to install and maintain. They can be easily fitted into existing coal processing equipment, reducing the need for extensive modifications. In terms of maintenance, PU sieve panels require minimal upkeep, further adding to their cost-effectiveness.

The use of PU sieve panels in coal processing is not just beneficial from a practical standpoint, but also from an environmental perspective. By improving the efficiency of the coal processing process, PU sieve panels can help to reduce the amount of coal that is wasted. This not only saves on resources but also helps to minimize the environmental impact of coal processing.

In conclusion, PU sieve panels offer a range of benefits that make them an ideal choice for use in coal processing plants. Their durability, efficiency, flexibility, and ease of maintenance, combined with their environmental benefits, make them a superior choice compared to other types of sieve panels. As the coal processing industry continues to evolve, it is likely that the use of PU sieve panels will become even more widespread, further enhancing the efficiency and sustainability of this vital industry.