urethane screen panels: Durability and Efficiency in Screening Applications

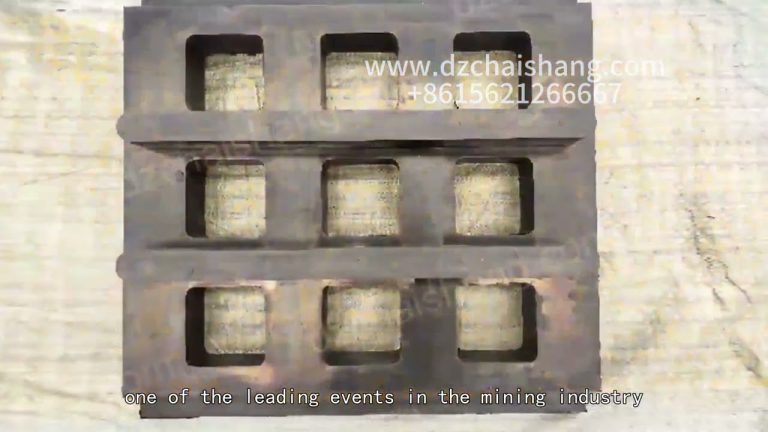

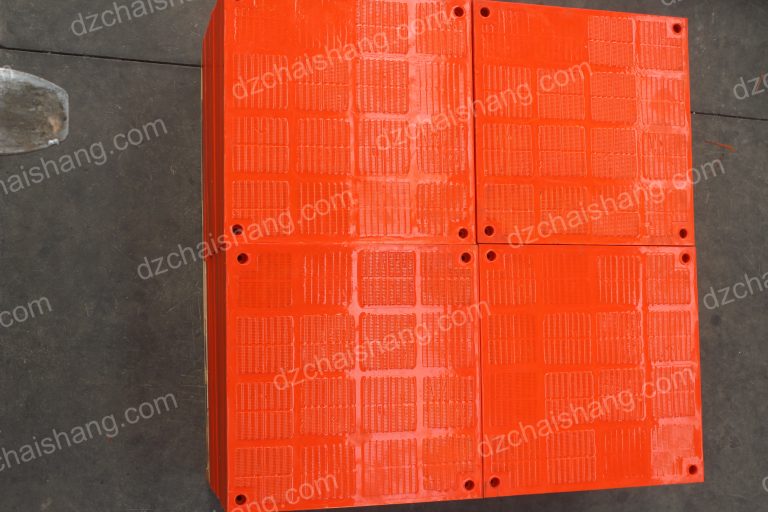

Urethane screen panels are an essential component in the mining and aggregate industries, where they are used in screening applications to separate different sizes of materials. These panels are made from polyurethane, a versatile polymer that offers superior durability and efficiency compared to traditional screening materials like wire mesh and rubber. Urethane screen panels are designed to withstand the harsh conditions of screening applications, including abrasion, corrosion, and impact. This makes them an ideal choice for use in dewatering screeners and shaker screens, where they can help to improve the efficiency and effectiveness of the screening process. Dewatering screeners are used to remove water from wet materials, such as sand, gravel, and coal. The urethane screen panels used in these screeners are designed to allow water to pass through while retaining the solid materials. This is achieved through a combination of the panel’s open area and the size of the openings in the screen. The open area of the screen is the percentage of the screen that is open to allow material to pass through. The size of the openings in the screen determines the size of the particles that can pass through. By carefully selecting the open area and the size of the openings, urethane screen panels can be optimized for specific dewatering applications. Shaker screens are another common application for urethane screen panels. These screens are used in the oil and gas industry to separate drilling fluids from cuttings. The urethane screen panels used in shaker screens are designed to provide a high level of vibration resistance, which helps to improve the efficiency of the screening process. The panels are also designed to resist wear and tear, which can help to extend the life of the screen and reduce maintenance costs. One of the key advantages of urethane screen panels is their ability to reduce blinding and pegging. Blinding occurs when the openings in the screen become blocked by particles that are too small to pass through. Pegging occurs when particles become lodged in the openings of the screen. Both of these issues can reduce the efficiency of the screening process and lead to increased maintenance costs. Urethane screen panels are designed to resist blinding and pegging, thanks to their smooth surface and flexible properties. This helps to keep the screen openings clear and allows for more efficient screening. In addition to their durability and efficiency, urethane screen panels also offer a number of other benefits. For example, they are lightweight and easy to install, which can help to reduce labor costs. They are also available in a variety of sizes and shapes, which allows them to be customized for specific applications. Furthermore, urethane screen panels are environmentally friendly, as they are made from a recyclable material.In conclusion, urethane screen panels are a highly effective and efficient solution for screening applications in the mining and aggregate industries. Their durability, resistance to wear and tear, and ability to reduce blinding and pegging make them an ideal choice for use in dewatering screeners and shaker screens. With their lightweight design and customizable options, urethane screen panels offer a cost-effective and environmentally friendly solution for screening applications.

Dewatering Screener: Key Features and Industry Applications

Dewatering screeners are essential equipment in various industries, playing a crucial role in the separation and removal of water from solid materials or soil. One of the key components of these machines is the urethane screen panels, which are highly valued for their durability and efficiency. Urethane, a synthetic material, is known for its exceptional resistance to abrasion, wear, and tear, making it an ideal choice for screening applications that involve harsh conditions and abrasive materials. The urethane screen panels are designed to handle heavy-duty screening applications, providing superior performance in terms of throughput and longevity. These panels are available in various sizes and configurations, allowing them to be customized to meet specific operational requirements. The flexibility of urethane also helps in reducing blinding and pegging, which are common issues in screening processes. This ensures a consistent flow of material and improves the overall efficiency of the dewatering screener. Another critical component of dewatering screeners is the shaker screen rubber. This rubber is used to mount and support the screen panels, providing a cushion that absorbs the vibrations and shocks during the screening process. The use of high-quality shaker screen rubber is vital as it directly affects the lifespan and effectiveness of the screen panels. By reducing the impact and wear, the rubber mounts help in maintaining the integrity of the urethane panels, thereby extending the service life of the screener. Dewatering screeners are widely used in industries such as mining, construction, and wastewater treatment. In mining operations, these screeners are used to separate water from minerals and ores, allowing for easier handling and processing of the materials. The robust design and high efficiency of urethane screen panels make them particularly suitable for this demanding application, where they need to withstand heavy loads and abrasive materials. In the construction industry, dewatering screeners are used to remove water from soil and aggregates. This is a critical step in preparing the materials for further use in construction projects, such as road building or concrete production. The ability of urethane screen panels to handle varying feed rates and material sizes makes them an excellent choice for this application, ensuring optimal performance and reliability. Wastewater treatment is another area where dewatering screeners play a vital role. These screeners are used to separate solids from liquids in the sludge, resulting in a drier solid product that is easier to handle and dispose of. The use of urethane screen panels in this application not only improves the efficiency of the separation process but also contributes to the overall sustainability of the treatment facility by reducing waste and increasing the recyclability of materials. In conclusion, dewatering screeners equipped with urethane screen panels and high-quality shaker screen rubber are indispensable tools in various industries. Their ability to efficiently separate solids from liquids, coupled with their durability and adaptability, makes them a valuable asset in operations that require reliable and effective material handling. As industries continue to evolve and face new challenges, the role of dewatering screeners and their components is likely to become even more significant, driving further innovations and improvements in screening technology.Shaker Screen Rubber: Enhancing Performance and Reducing Noise in Shale Shakers

Shaker Screen Rubber: Enhancing Performance and Reducing Noise in Shale Shakers In the oil and gas industry, shale shakers are essential equipment used for separating solids from drilling fluids. The efficiency of these machines is crucial for maintaining the quality of the drilling operation and minimizing environmental impact. One of the key components that play a significant role in the performance of shale shakers is the shaker screen rubber. This material is designed to enhance the durability and effectiveness of the screening process, while also reducing the noise generated during operation. Shaker screen rubber is typically made from high-quality urethane, which is known for its excellent resistance to abrasion, tearing, and impact. This makes it an ideal choice for use in harsh drilling environments where the screens are subjected to heavy loads and constant wear and tear. The urethane screen panels are engineered to provide a perfect balance between flexibility and strength, ensuring that they can effectively handle large volumes of drilling fluids without suffering damage. The design of urethane screen panels also plays a crucial role in their performance. These panels are often constructed with a tapered relief pattern, which helps to prevent the accumulation of solids on the screen surface. This design feature allows for more efficient separation of solids from the drilling fluids, leading to improved drilling performance and reduced waste. Additionally, the tapered relief pattern helps to distribute the load more evenly across the screen, which can extend the lifespan of the screen and reduce the need for frequent replacements. Another important aspect of shaker screen rubber is its ability to reduce noise levels during operation. Shale shakers are known for generating significant amounts of noise, which can be a major concern in terms of workplace safety and environmental regulations. The use of high-quality urethane screen panels can help to dampen the noise generated by the shakers, making them more compliant with noise regulations and creating a safer working environment for personnel. In addition to its noise-reducing properties, shaker screen rubber also offers excellent resistance to chemicals and temperature extremes. This makes it suitable for use in a wide range of drilling conditions, including those involving corrosive fluids or extreme temperatures. The chemical and temperature resistance of urethane screen panels ensures that they can maintain their performance and durability even in the most challenging environments. The use of a dewatering screener is another important consideration in the context of shale shakers. This equipment is designed to remove excess water from the drilling fluids, which can help to improve the efficiency of the separation process and reduce the volume of waste generated. The combination of a high-quality shaker screen rubber and an effective dewatering screener can significantly enhance the overall performance of shale shakers, leading to better drilling outcomes and reduced environmental impact. In conclusion, shaker screen rubber is a critical component in the operation of shale shakers in the oil and gas industry. The use of high-quality urethane screen panels can enhance the durability and effectiveness of the screening process, reduce noise levels, and improve compliance with environmental regulations. By incorporating advanced materials and equipment such as dewatering screeners, operators can further optimize the performance of their shale shakers and achieve more efficient and sustainable drilling operations.