Entender a importancia das placas finas de uretano nas explotacións mineiras

O sistema de tensión directa empregado nas aplicacións de cubertas de uretano mellora aínda máis o seu rendemento e lonxevidade. Ao eliminar a necesidade de métodos de fixación tradicionais, como parafusos ou clips, este sistema minimiza as concentracións de tensión e os posibles puntos de falla. Como resultado, as plataformas de uretano poden soportar cargas máis elevadas e operar a velocidades elevadas sen comprometer a integridade, maximizando así o tempo de actividade e a produtividade.

Os beneficios das placas finas de uretano van máis aló da eficiencia operativa para abarcar tamén as consideracións ambientais. En comparación cos materiais tradicionais como o aceiro, o uretano ofrece unha resistencia á corrosión superior, reducindo o risco de contaminación por ferruxe ou produtos de corrosión. Ademais, o uretano é non tóxico e inerte, polo que supón un impacto ambiental mínimo durante todo o seu ciclo de vida. Isto aliña coa crecente énfase nas prácticas sostibles dentro da industria mineira, o que subliña aínda máis a relevancia das placas finas de uretano nas operacións mineiras modernas.

En conclusión, as placas finas de uretano xogan un papel vital na mellora da eficiencia, fiabilidade e sustentabilidade da minería. operacións. A súa excepcional durabilidade, versatilidade e rendemento fan que sexan compoñentes indispensables nos procesos de selección, clasificación e clasificación. A medida que a industria mineira continúa evolucionando, espérase que aumente a demanda de solucións innovadoras como placas finas de uretano, impulsando novos avances e aplicacións no campo.

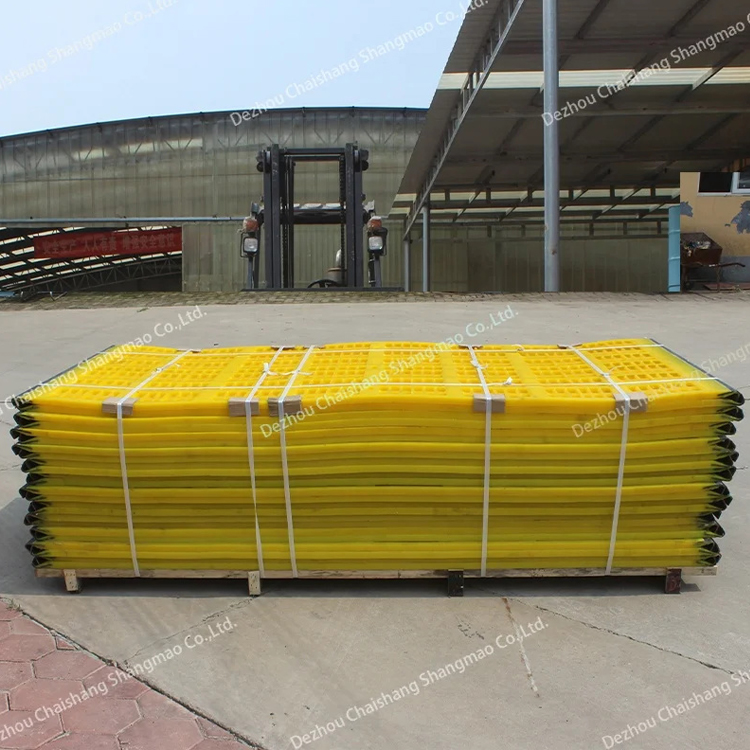

One of the primary applications of urethane fine plates in mining is in screening operations. These plates are commonly used in vibrating screens, where they serve as the screening surface. Their high abrasion resistance enables them to withstand the constant friction and impact from the materials being processed, thereby maintaining screening efficiency over extended periods. Additionally, their flexibility allows them to conform to the contours of the screen deck, ensuring optimal contact and screening performance.

Beyond screening, urethane fine plates also find utility in sorting and classification processes within mining operations. Whether separating ores based on size, density, or other characteristics, these plates offer precise and reliable performance. Their smooth surface minimizes material adhesion and blinding, preventing clogging and ensuring uninterrupted operation. This is particularly critical in high-throughput applications where efficiency is paramount.

In addition to their mechanical properties, urethane fine plates offer advantages in terms of customization and versatility. Manufacturers can tailor the plates to meet specific size, shape, and aperture requirements, allowing for seamless integration into diverse mining equipment and processes. Furthermore, advancements in urethane formulation have led to the development of specialty plates with enhanced properties such as increased abrasion resistance or improved flexibility, catering to the evolving needs of the mining industry.

The direct tensioning system employed in urethane deck applications further enhances their performance and longevity. By eliminating the need for traditional fastening methods such as bolts or clips, this system minimizes stress concentrations and potential points of failure. As a result, urethane decks can withstand higher loads and operate at elevated speeds without compromising integrity, thereby maximizing uptime and productivity.

The benefits of urethane fine plates extend beyond operational efficiency to encompass environmental considerations as well. Compared to traditional materials such as steel, urethane offers superior corrosion resistance, reducing the risk of contamination from rust or corrosion products. Additionally, urethane is non-toxic and inert, posing minimal environmental impact throughout its lifecycle. This aligns with the growing emphasis on sustainable practices within the mining industry, further underscoring the relevance of urethane fine plates in modern mining operations.

In conclusion, urethane fine plates play a vital role in enhancing the efficiency, reliability, and sustainability of mining operations. Their exceptional durability, versatility, and performance make them indispensable components in screening, sorting, and classification processes. As the mining industry continues to evolve, the demand for innovative solutions like urethane fine plates is expected to rise, driving further advancements and applications in the field.