Advantages Of High Elasticity polyurethane screen mesh In vibrating screen panels

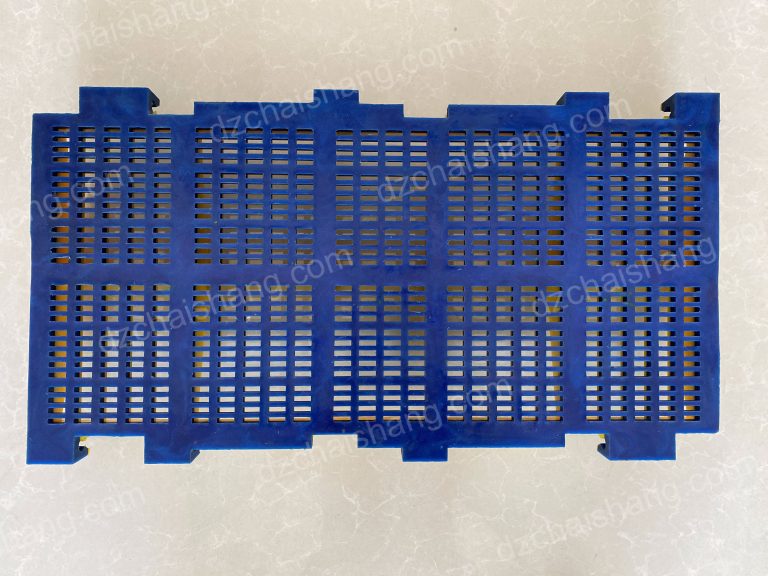

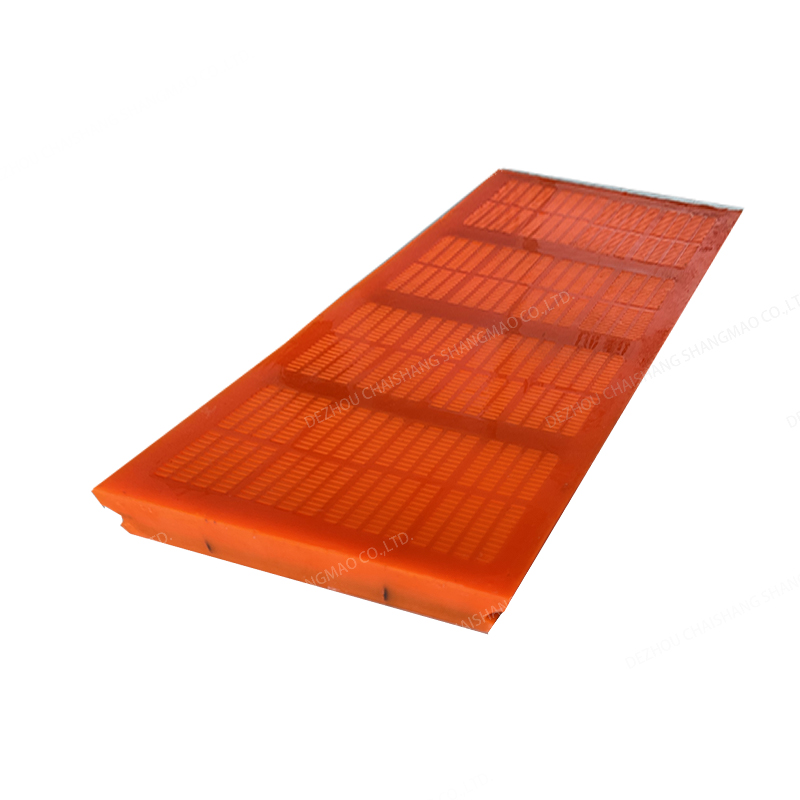

High elasticity polyurethane screen mesh is increasingly becoming the material of choice for vibrating screen panels in various industrial applications. This preference is largely due to its exceptional properties that offer significant advantages over traditional materials like wire mesh or rubber. Understanding these benefits can help industries make informed decisions when selecting materials for their screening needs.

Furthermore, the noise reduction capabilities of polyurethane screen mesh cannot be overlooked. In industrial environments, where noise levels can significantly impact worker safety and comfort, polyurethane screens offer a quieter operation compared to metal screens. The material’s inherent properties help absorb the vibration and reduce the sound produced during the screening process. This contributes not only to a more pleasant working environment but also to compliance with regulations regarding noise control. Additionally, the customization possibilities with polyurethane screen mesh are extensive. Manufacturers can tailor aspects such as thickness, aperture size, and panel size to meet specific operational requirements. This level of customization ensures that the screening process is optimized for efficiency and effectiveness, regardless of the application. Whether it’s sorting coarse aggregates or fine sand, polyurethane screens can be engineered to perform at optimal levels. Lastly, the overall cost-effectiveness of high elasticity polyurethane screen mesh is a compelling advantage. While the initial investment in polyurethane screen panels may be higher than that of other materials, the long-term savings are significant. The durability and reduced maintenance needs of polyurethane contribute to lower lifecycle costs. Additionally, the improved screening efficiency and product quality can lead to better output and fewer material losses, further enhancing the economic benefits. In conclusion, high elasticity polyurethane screen mesh offers numerous advantages for vibrating screen panels, making it a superior choice for many industrial applications. Its durability, efficiency, noise reduction capabilities, customization options, and cost-effectiveness make it an ideal solution for companies looking to improve their screening processes. As industries continue to seek ways to enhance operational efficiency and reduce costs, the adoption of polyurethane screen mesh is likely to grow, reflecting its substantial benefits in meeting these objectives.