Benefits of Using polyurethane Tailings dewatering screen Plate

Polyurethane tailings dewatering screen plates have gained significant popularity in various industries due to their numerous benefits. These screen plates are widely used in the mining, coal, and construction sectors, among others, to efficiently separate solid particles from liquids. In this article, we will explore the benefits of using polyurethane tailings dewatering screen plates and discuss their unique characteristics.

One of the key advantages of polyurethane tailings dewatering screen plates is their exceptional wear resistance. These screen plates are designed to withstand the harsh conditions of mining and other heavy-duty applications. The polyurethane material used in their construction is highly durable and can withstand the abrasive nature of the materials being processed. This wear resistance ensures a longer lifespan for the screen plates, reducing the need for frequent replacements and saving costs for businesses.

In addition to their wear resistance, polyurethane tailings dewatering screen plates also offer excellent corrosion resistance. This is particularly important in industries where the processed materials contain corrosive substances. The polyurethane material is resistant to chemicals and acids, ensuring that the screen plates remain intact and functional even in corrosive environments. This corrosion resistance further contributes to the longevity of the screen plates and enhances their overall performance.

Another significant benefit of using polyurethane tailings dewatering screen plates is their high screening efficiency. These screen plates are designed with precise openings that allow for efficient separation of solid particles from liquids. The polyurethane material used in their construction has excellent elasticity, which enables the screen plates to effectively bounce back after each screening process. This elasticity ensures that the screen plates maintain their shape and integrity, resulting in a more efficient and accurate separation process.

Furthermore, polyurethane tailings dewatering screen plates offer enhanced noise reduction compared to traditional screen plates. The polyurethane material has excellent sound absorption properties, which helps to minimize noise levels during the screening process. This is particularly beneficial in industries where noise pollution is a concern, such as residential areas near mining sites. The reduced noise levels not only contribute to a more comfortable working environment but also help to comply with noise regulations and standards.

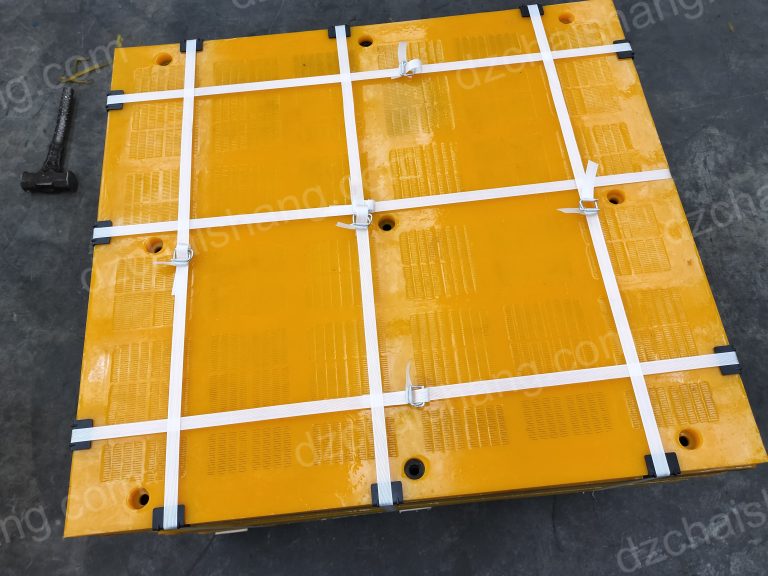

Additionally, polyurethane tailings dewatering screen plates are lightweight and easy to install. Their lightweight nature makes them easier to handle and transport, reducing the labor and time required for installation. This is particularly advantageous in industries where frequent screen plate replacements are necessary. The ease of installation also allows for quick maintenance and replacement, minimizing downtime and maximizing productivity.

In conclusion, the application of polyurethane tailings dewatering screen plates offers numerous benefits in various industries. Their exceptional wear and corrosion resistance, high screening efficiency, noise reduction, and ease of installation make them a preferred choice for businesses. These screen plates not only improve the overall performance and longevity of the screening process but also contribute to a more efficient and environmentally friendly operation. With their unique characteristics, polyurethane tailings dewatering screen plates have become an indispensable tool in the modern industrial landscape.