The Importance of Choosing the Right vibrating screen mesh material

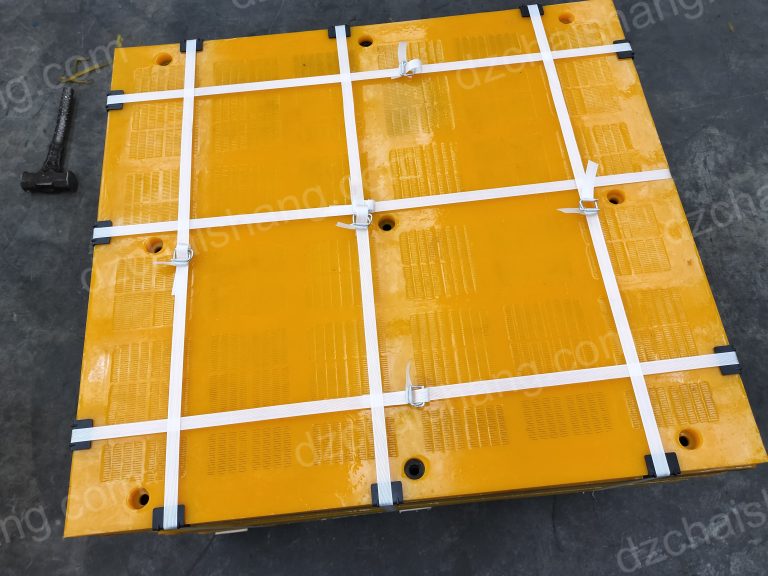

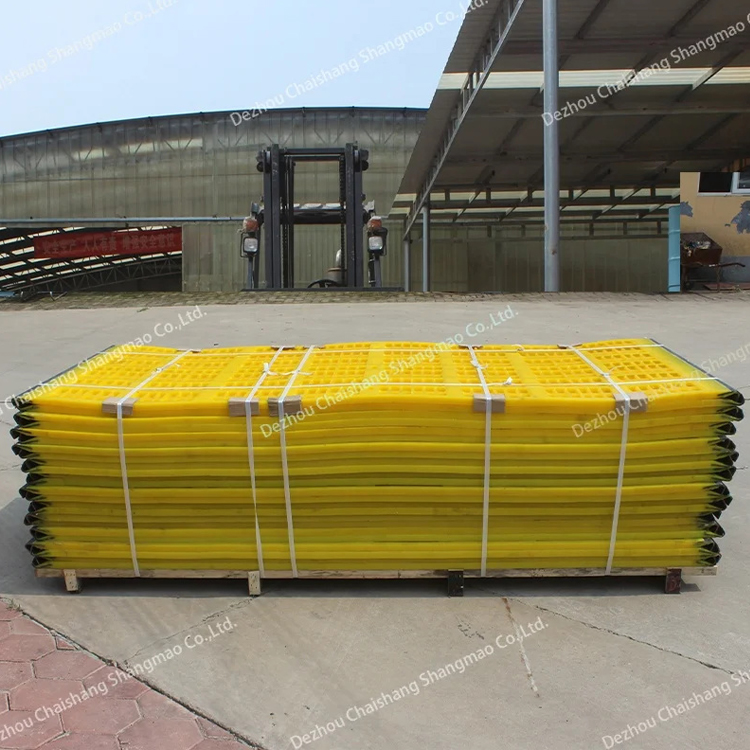

The vibrating screen is a crucial piece of equipment in many industries, including mining, construction, and agriculture. It is used to separate materials based on their size and shape, ensuring that only the desired particles pass through while the rest are discarded. One of the key components of a vibrating screen is the mesh material that covers the screen surface. This mesh material plays a vital role in determining the efficiency and effectiveness of the screening process. Therefore, it is of utmost importance to choose the right vibrating screen mesh material.

There are several factors to consider when selecting the mesh material for a vibrating screen. The first and most obvious factor is the material being screened. Different materials have different properties, such as hardness, abrasiveness, and moisture content. These properties can have a significant impact on the wear and tear of the mesh material. For example, if the material being screened is abrasive, a mesh material with high abrasion resistance should be chosen to ensure a longer lifespan of the screen.

Another important factor to consider is the required screening efficiency. The mesh material should be able to effectively separate the desired particles from the undesired ones. This requires a mesh with the appropriate opening size. If the openings are too large, the desired particles may pass through along with the undesired ones, resulting in a lower screening efficiency. On the other hand, if the openings are too small, the desired particles may get trapped in the mesh, reducing the overall throughput of the screening process. Therefore, it is crucial to choose a mesh material with the right opening size for the specific application.

In addition to the material being screened and the required screening efficiency, the operating conditions of the vibrating screen should also be taken into account when selecting the mesh material. Factors such as temperature, humidity, and exposure to corrosive substances can affect the performance and lifespan of the mesh. For example, if the vibrating screen is operating in a high-temperature environment, a mesh material with high heat resistance should be chosen to prevent deformation or melting of the mesh. Similarly, if the screen is exposed to corrosive substances, a mesh material with good corrosion resistance should be selected to avoid premature failure.

Furthermore, the maintenance and cleaning requirements of the mesh material should be considered. Some mesh materials are easier to clean and maintain than others. For example, stainless steel mesh is known for its easy cleaning and low maintenance requirements. On the other hand, mesh materials made of synthetic fibers may require more frequent cleaning and replacement. Therefore, the ease of maintenance and cleaning should be taken into account when choosing the mesh material.

In conclusion, the choice of vibrating screen mesh material is of utmost importance in ensuring the efficiency and effectiveness of the screening process. Factors such as the material being screened, the required screening efficiency, the operating conditions, and the maintenance requirements should all be considered when selecting the mesh material. By choosing the right mesh material, industries can optimize their screening processes, improve productivity, and reduce downtime and maintenance costs.