Benefits of Using polyurethane dewatering panels in mining Operations

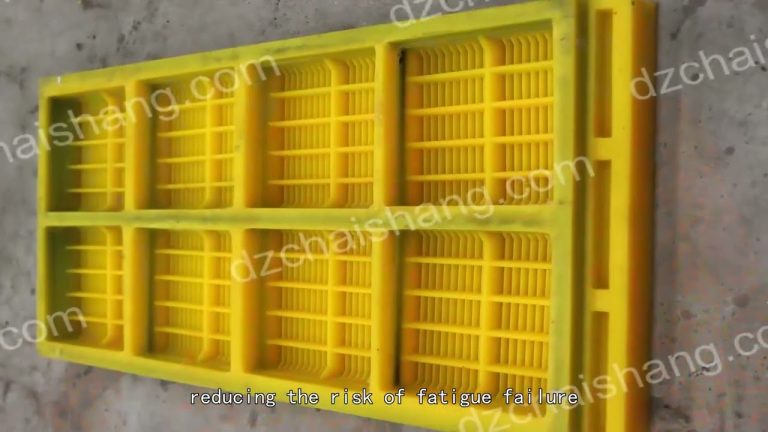

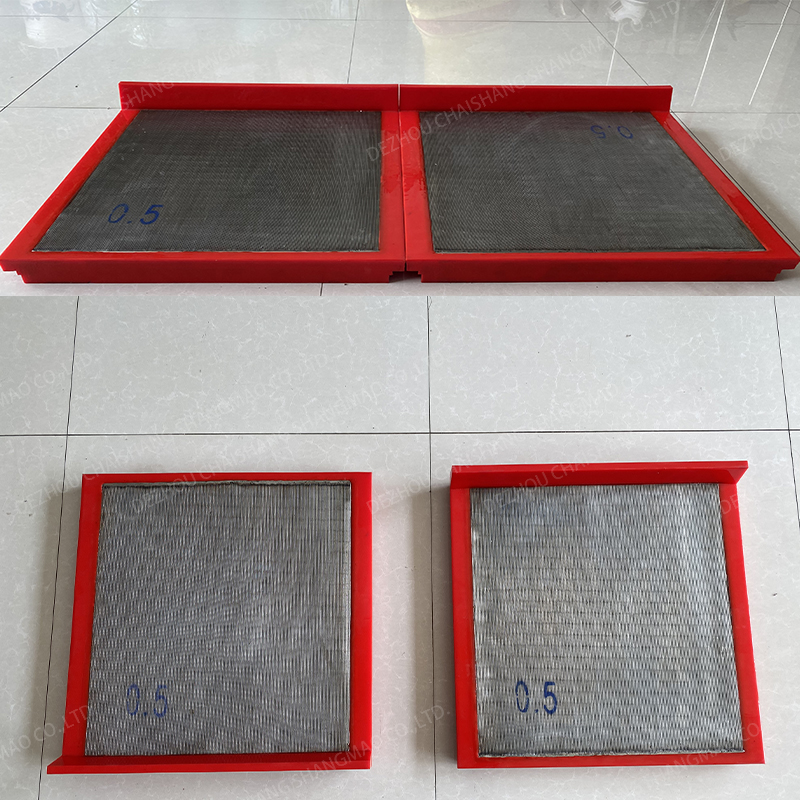

Polyurethane dewatering panels have become increasingly popular in the mining industry due to their numerous benefits and advantages over traditional steel or rubber panels. These panels are designed to efficiently separate solids from liquids in the dewatering process, making them an essential component in mining operations. In this article, we will explore the benefits of using polyurethane dewatering panels and how they can improve the efficiency and productivity of mining operations. One of the key advantages of polyurethane dewatering panels is their durability and longevity. Unlike steel or rubber panels, Polyurethane Panels are resistant to wear and tear, making them ideal for harsh mining environments. This durability ensures that the panels can withstand the high pressures and abrasive materials commonly found in mining operations, reducing the need for frequent replacements and maintenance. In addition to their durability, polyurethane dewatering panels are also lightweight and easy to install. This makes them a cost-effective solution for mining companies looking to improve their dewatering processes without incurring significant expenses. The lightweight nature of polyurethane panels also makes them easier to handle and transport, reducing the time and effort required for installation. Furthermore, polyurethane dewatering panels are highly efficient in separating solids from liquids, resulting in a more effective dewatering process. The unique design of these panels allows for optimal drainage and filtration, ensuring that the desired separation is achieved quickly and efficiently. This efficiency can lead to increased productivity and reduced downtime in mining operations, ultimately improving overall performance and profitability. Another benefit of using polyurethane dewatering panels is their versatility and customization options. These panels can be tailored to meet the specific needs and requirements of each mining operation, allowing for greater flexibility and adaptability. Whether it’s adjusting the panel size, shape, or aperture size, polyurethane panels can be customized to optimize performance and maximize efficiency. Additionally, polyurethane dewatering panels are environmentally friendly and sustainable. These panels are made from recyclable materials, reducing the environmental impact of mining operations. By using polyurethane panels, mining companies can minimize their carbon footprint and contribute to a more sustainable future. Overall, the benefits of using polyurethane dewatering panels in mining operations are clear. From their durability and efficiency to their versatility and sustainability, these panels offer a range of advantages that can significantly improve the performance and profitability of mining operations. By investing in polyurethane dewatering panels, mining companies can enhance their dewatering processes and achieve greater success in their operations.How modular panels Can Improve Efficiency in Dewatering Systems

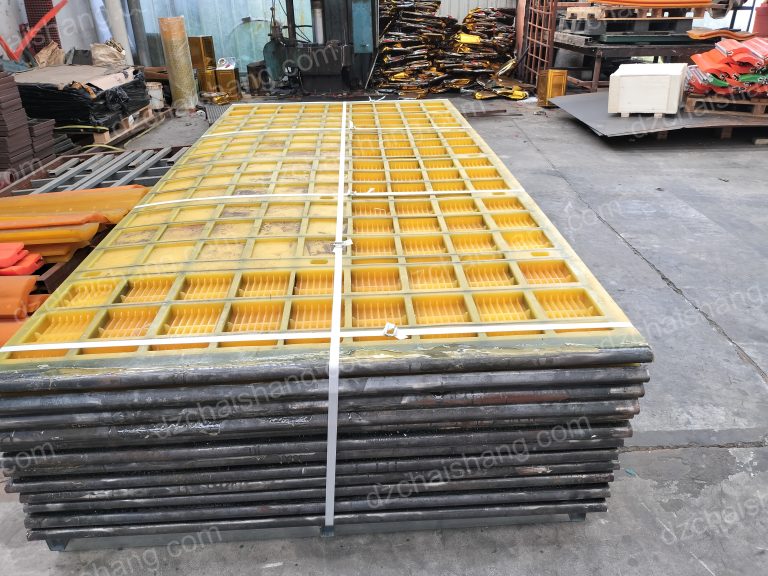

Dewatering systems are essential in various industries to separate solids from liquids, ensuring efficient processes and reducing waste. One key component of dewatering systems is the use of polyurethane dewatering panels, which play a crucial role in the filtration and separation process. These panels are designed to withstand the harsh conditions of dewatering operations, providing durability and efficiency in the filtration process. Modular panels, in particular, offer several advantages in dewatering systems. These panels are designed to be easily interchangeable, allowing for quick and efficient maintenance and replacement. This modularity also allows for customization of the dewatering system to meet specific requirements, ensuring optimal performance and efficiency.One of the main benefits of modular panels is their ease of installation. These panels can be quickly and easily installed, reducing downtime and increasing productivity. Additionally, modular panels can be easily removed and replaced, allowing for quick maintenance and minimizing disruptions to the dewatering process. Another advantage of modular panels is their versatility. These panels can be customized to fit different dewatering systems, making them suitable for a wide range of applications. Whether used in mining, wastewater treatment, or industrial processes, modular panels can improve efficiency and performance in dewatering operations. In addition to their ease of installation and versatility, modular panels also offer cost savings. These panels are designed to be durable and long-lasting, reducing the need for frequent replacements. This not only saves on maintenance costs but also ensures consistent performance and efficiency in dewatering systems. Furthermore, modular panels are designed to improve the overall efficiency of dewatering systems. By providing a reliable and consistent filtration process, these panels help to reduce waste and increase the recovery of valuable materials. This not only improves the sustainability of dewatering operations but also enhances the overall profitability of the process.

Overall, modular panels offer a range of benefits in dewatering systems. From their ease of installation and versatility to their cost savings and efficiency improvements, these panels play a crucial role in optimizing the performance of dewatering operations. By incorporating modular panels into their systems, industries can enhance productivity, reduce downtime, and improve the overall efficiency of their dewatering processes. In conclusion, modular panels are a valuable component in dewatering systems, offering a range of benefits that can improve efficiency and performance. With their ease of installation, versatility, and cost savings, these panels are an essential tool for industries looking to optimize their dewatering operations. By investing in modular panels, businesses can enhance their processes, reduce waste, and increase profitability in their dewatering systems.