Benefits of Using High Quality polyurethane vibrating screen mesh

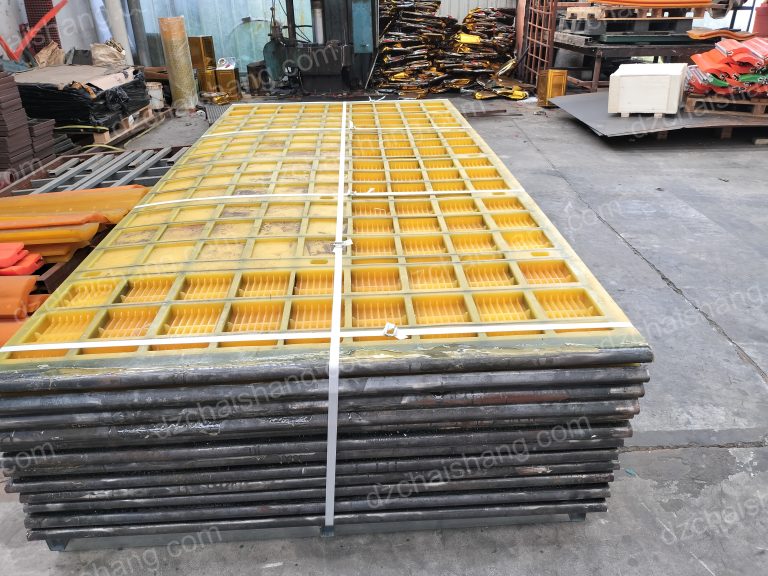

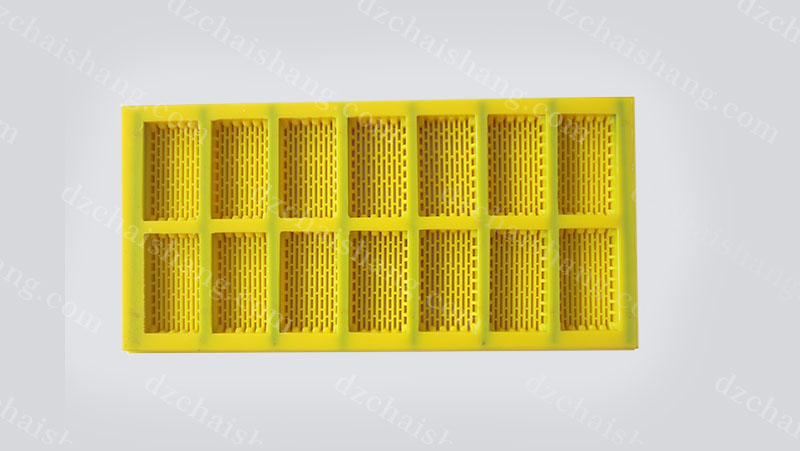

High quality polyurethane VIBRATING screen mesh is a popular choice for many industries due to its durability, flexibility, and efficiency. This type of screen mesh is made from polyurethane, a synthetic material that offers numerous benefits over traditional metal or rubber screen meshes. One of the key advantages of using high quality polyurethane vibrating screen mesh is its durability. Polyurethane is a strong and resilient material that can withstand heavy use and harsh conditions without losing its shape or effectiveness. This means that polyurethane screen meshes are less likely to break or wear out, resulting in lower maintenance costs and longer service life. In addition to its durability, polyurethane vibrating screen mesh is also highly flexible. This flexibility allows the mesh to conform to the shape of the vibrating screen, ensuring a tight and secure fit. This tight fit helps to prevent material from slipping through the screen, resulting in more efficient screening and higher productivity. Another benefit of using high quality polyurethane vibrating screen mesh is its efficiency. polyurethane mesh is designed to allow for maximum airflow and drainage, which helps to prevent clogging and blinding. This means that materials can be screened more quickly and effectively, resulting in higher throughput and improved product quality. Furthermore, polyurethane vibrating screen mesh is resistant to abrasion, corrosion, and chemicals. This makes it ideal for use in industries such as mining, quarrying, and construction, where screens are exposed to abrasive materials and harsh environments. Polyurethane mesh is also easy to clean and maintain, making it a cost-effective and low-maintenance option for many applications. Overall, the benefits of using high quality polyurethane vibrating screen mesh are clear. Its durability, flexibility, efficiency, and resistance to abrasion make it a superior choice for many industries. By investing in polyurethane screen mesh, businesses can improve their screening processes, increase productivity, and reduce maintenance costs in the long run.

In conclusion, high quality polyurethane vibrating screen mesh offers numerous advantages over traditional screen meshes. Its durability, flexibility, efficiency, and resistance to abrasion make it a superior choice for many industries. By choosing polyurethane mesh, businesses can improve their screening processes, increase productivity, and reduce maintenance costs.

Overall, the benefits of using high quality polyurethane vibrating screen mesh are clear. Its durability, flexibility, efficiency, and resistance to abrasion make it a superior choice for many industries. By investing in polyurethane screen mesh, businesses can improve their screening processes, increase productivity, and reduce maintenance costs in the long run.

In conclusion, high quality polyurethane vibrating screen mesh offers numerous advantages over traditional screen meshes. Its durability, flexibility, efficiency, and resistance to abrasion make it a superior choice for many industries. By choosing polyurethane mesh, businesses can improve their screening processes, increase productivity, and reduce maintenance costs.

How to Choose the Best High Quality Polyurethane Vibrating Screen Mesh for Your Application

When it comes to choosing the best high-quality polyurethane vibrating screen mesh for your application, there are several factors to consider. Polyurethane vibrating screen mesh is a popular choice for many industries due to its durability, flexibility, and resistance to abrasion. However, not all polyurethane vibrating screen mesh is created equal, and it’s important to select the right type for your specific needs. One of the first things to consider when choosing polyurethane vibrating screen mesh is the aperture size. The aperture size refers to the space between the wires in the mesh, and it can have a significant impact on the performance of the screen. A smaller aperture size is ideal for applications where fine particles need to be separated, while a larger aperture size is better suited for larger particles. It’s important to consider the size of the particles you will be working with when selecting the aperture size of the mesh. Another important factor to consider is the wire diameter of the polyurethane vibrating screen mesh. The wire diameter refers to the thickness of the wires used to create the mesh, and it can affect the strength and durability of the screen. Thicker wires are more durable and can withstand heavier loads, while thinner wires are more flexible and can provide better screening performance. It’s important to choose a wire diameter that is appropriate for the type of material you will be screening and the amount of wear and tear the screen will be subjected to. In addition to aperture size and wire diameter, it’s also important to consider the type of polyurethane used in the vibrating screen mesh. There are different types of polyurethane available, each with its own unique properties and advantages. For example, some types of polyurethane are more resistant to abrasion, while others are more flexible and can provide better screening performance. It’s important to choose a type of polyurethane that is best suited for your specific application and will provide the durability and performance you need. When selecting polyurethane vibrating screen mesh, it’s also important to consider the overall design of the screen. The design of the screen can affect its performance and efficiency, so it’s important to choose a design that is well-suited for your specific application. Some screens are designed with a higher open area, which allows for better screening efficiency and throughput, while others are designed with a tighter weave for better particle separation. It’s important to consider the design of the screen and how it will impact the performance of your application.In conclusion, choosing the best high-quality polyurethane vibrating screen mesh for your application requires careful consideration of several factors. From aperture size and wire diameter to the type of polyurethane used and the overall design of the screen, there are many factors to consider when selecting the right mesh for your needs. By taking the time to carefully evaluate these factors and choose a mesh that is well-suited for your specific application, you can ensure that you get the best performance and durability from your vibrating screen mesh.