Explorer l’efficacité des supports de tamis vibrant en PU à prix d’usine

Comprendre la fonctionnalité des panneaux grillagés de déshydratation

Understanding the Functionality of dewatering screen mesh Panels

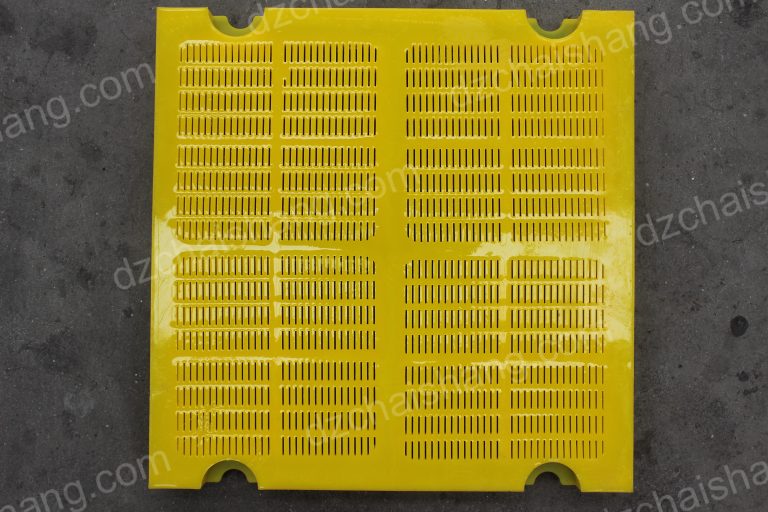

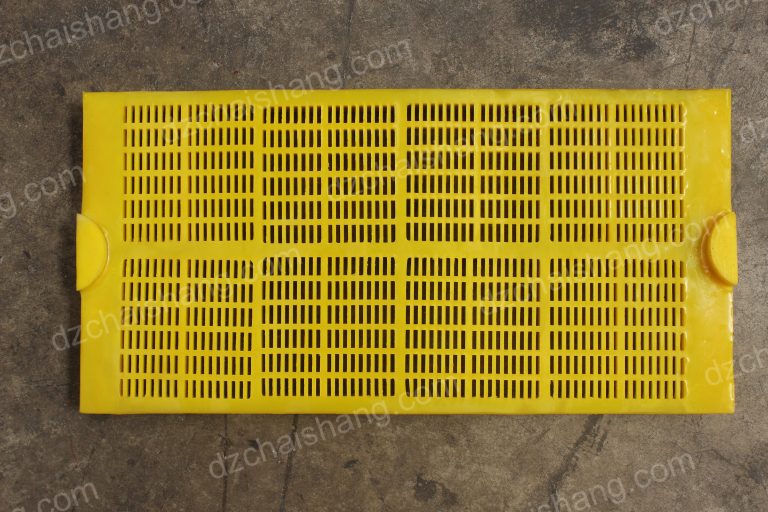

Understanding the functionality of dewatering screen mesh panels is crucial in various industries, particularly in mining, construction, and waste management. These panels play a significant role in separating solids from liquids, a process that is essential in these sectors. The dewatering screen mesh panels, often made from polyurethane (PU), are designed to withstand the rigors of heavy-duty applications, providing durability and efficiency in the dewatering process.

The PU vibrating screen media, also known as dewatering screen panels, are typically used in vibrating deck screens. These panels are designed to handle high volumes of materials, and their primary function is to separate water or other liquids from solids. The panels are made from polyurethane, a material known for its excellent abrasion resistance and long service life. This makes them ideal for use in industries where wear and tear are common, such as mining and construction.

The dewatering process begins when the material is fed onto the screen. The vibrating action of the screen causes the water to be separated from the solids. The water passes through the screen mesh, while the solids are retained on top. The result is a drier material that is easier to handle and transport. This process is not only efficient but also environmentally friendly as it reduces the amount of water waste.

The effectiveness of the dewatering process largely depends on the quality of the dewatering screen mesh panel. The panel’s design and the size of the mesh openings are critical factors in determining the efficiency of the dewatering process. Smaller mesh openings allow for finer screening, which results in a drier end product. On the other hand, larger mesh openings are used for coarser screening, which may be necessary for certain applications.

The factory price pu vibrating screen media offers a cost-effective solution for dewatering needs. Despite their high performance and durability, these panels are reasonably priced, making them an attractive option for businesses looking to optimize their operations while keeping costs low. Moreover, these panels are easy to install and replace, further reducing operational costs.

In addition to their functionality, dewatering screen mesh panels also offer several benefits. For instance, they improve the efficiency of the dewatering process, resulting in significant cost savings. They also reduce the environmental impact by minimizing water waste. Furthermore, the use of polyurethane in their construction ensures they are resistant to wear and tear, thereby extending their lifespan and reducing the need for frequent replacements.

In conclusion, understanding the functionality of dewatering screen mesh panels is essential for industries that require the separation of solids from liquids. These panels, often made from polyurethane, offer a durable and efficient solution for the dewatering process. Their design and the size of the mesh openings play a crucial role in determining the efficiency of the process. Despite their high performance, these panels are reasonably priced, making them a cost-effective solution for businesses. Their benefits, such as improved efficiency, reduced environmental impact, and extended lifespan, make them an invaluable asset in various industries.