Comprendre l’importance des plaques fines d’uréthane dans les opérations minières

Le système de tension directe utilisé dans les applications de terrasses en uréthane améliore encore leurs performances et leur longévité. En éliminant le besoin de méthodes de fixation traditionnelles telles que les boulons ou les clips, ce système minimise les concentrations de contraintes et les points de défaillance potentiels. En conséquence, les terrasses en uréthane peuvent supporter des charges plus élevées et fonctionner à des vitesses élevées sans compromettre leur intégrité, maximisant ainsi la disponibilité et la productivité.

Les avantages des plaques fines en uréthane s’étendent au-delà de l’efficacité opérationnelle pour englober également les considérations environnementales. Comparé aux matériaux traditionnels tels que l’acier, l’uréthane offre une résistance supérieure à la corrosion, réduisant ainsi le risque de contamination par la rouille ou les produits de corrosion. De plus, l’uréthane est non toxique et inerte, ce qui présente un impact minimal sur l’environnement tout au long de son cycle de vie. Cela correspond à l’importance croissante accordée aux pratiques durables au sein de l’industrie minière, soulignant encore davantage la pertinence des plaques fines d’uréthane dans les opérations minières modernes.

En conclusion, les plaques fines d’uréthane jouent un rôle essentiel dans l’amélioration de l’efficacité, de la fiabilité et de la durabilité de l’exploitation minière. opérations. Leur durabilité, leur polyvalence et leurs performances exceptionnelles en font des composants indispensables dans les processus de criblage, de tri et de classification. À mesure que l’industrie minière continue d’évoluer, la demande de solutions innovantes telles que les plaques fines en uréthane devrait augmenter, entraînant de nouvelles avancées et applications dans ce domaine.

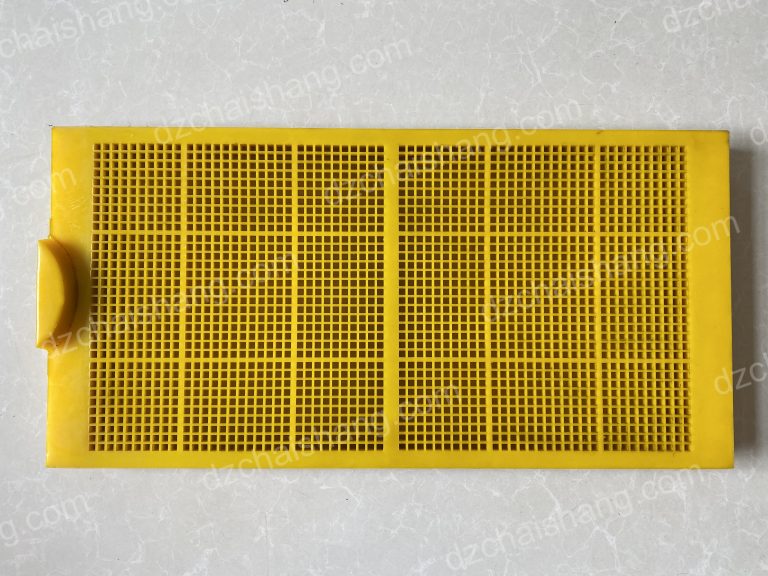

One of the primary applications of urethane fine plates in mining is in screening operations. These plates are commonly used in vibrating screens, where they serve as the screening surface. Their high abrasion resistance enables them to withstand the constant friction and impact from the materials being processed, thereby maintaining screening efficiency over extended periods. Additionally, their flexibility allows them to conform to the contours of the screen deck, ensuring optimal contact and screening performance.

Beyond screening, urethane fine plates also find utility in sorting and classification processes within mining operations. Whether separating ores based on size, density, or other characteristics, these plates offer precise and reliable performance. Their smooth surface minimizes material adhesion and blinding, preventing clogging and ensuring uninterrupted operation. This is particularly critical in high-throughput applications where efficiency is paramount.

In addition to their mechanical properties, urethane fine plates offer advantages in terms of customization and versatility. Manufacturers can tailor the plates to meet specific size, shape, and aperture requirements, allowing for seamless integration into diverse mining equipment and processes. Furthermore, advancements in urethane formulation have led to the development of specialty plates with enhanced properties such as increased abrasion resistance or improved flexibility, catering to the evolving needs of the mining industry.

The direct tensioning system employed in urethane deck applications further enhances their performance and longevity. By eliminating the need for traditional fastening methods such as bolts or clips, this system minimizes stress concentrations and potential points of failure. As a result, urethane decks can withstand higher loads and operate at elevated speeds without compromising integrity, thereby maximizing uptime and productivity.

The benefits of urethane fine plates extend beyond operational efficiency to encompass environmental considerations as well. Compared to traditional materials such as steel, urethane offers superior corrosion resistance, reducing the risk of contamination from rust or corrosion products. Additionally, urethane is non-toxic and inert, posing minimal environmental impact throughout its lifecycle. This aligns with the growing emphasis on sustainable practices within the mining industry, further underscoring the relevance of urethane fine plates in modern mining operations.

In conclusion, urethane fine plates play a vital role in enhancing the efficiency, reliability, and sustainability of mining operations. Their exceptional durability, versatility, and performance make them indispensable components in screening, sorting, and classification processes. As the mining industry continues to evolve, the demand for innovative solutions like urethane fine plates is expected to rise, driving further advancements and applications in the field.