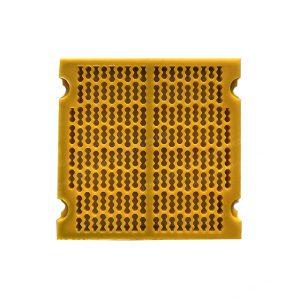

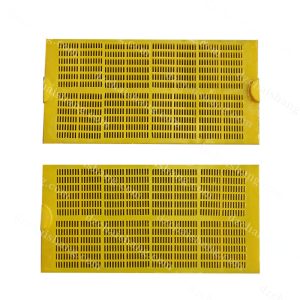

305x305x30 Aperture 8×25 Polyurethane Modular Screens

Material: Polyurethane

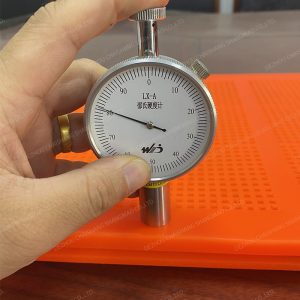

Hardness: 80-95 Shore A

Size: Can be customized

Customization: Available

Standard service life: 6~12 months

Delivery: 15-45 days depending on the quantity

- Satisfaction Guaranteed

- Accurate dimensions

- Guaranteed installation

- On-time delivery

The skeleton polyurethane screen plate is an ideal choice for screening a variety of materials, especially suitable for screening wet or dry materials. There are also a variety of formulations available, including highly elastic polyurethane formulations that minimize clogging.

Can be customized according to your special requirements.

Aperture options: square holes, strip holes, circular holes, continuous grooves, etc., screening particle size 0.1mm to 170mm.

Features

Excellent wear resistance and long service life: the service life is 8~10 times longer than ordinary metal wire mesh, 3 times longer than stainless steel wire mesh, and 3.9 times longer than natural rubber. It is currently the best wear resistance in the world Screen material.

The maintenance workload is small. The polyurethane frame screen plate is suitable for working under heavy loads and will hardly be damaged under normal operation. Due to less maintenance and downtime, a lot of time and energy are saved, which can greatly improve the working efficiency of the screen machine and reduce the operating cost of the station.

3. Our polyurethane and rubber screens can reduce noise levels by up to 9 decibels. This is a 50% reduction in noise perceived by the human ear. This means staff can work nearby for longer without damaging their hearing.

4. A variety of fixing methods are available, including pin fixing, bolt fixing, clip-on and batten connection and other installation methods. Whether you require the most secure installation, ease of installation and removal, optimal versatility or a combination of all, we have a mounting system to suit your needs.

Application: Especially suitable for screening wet and dry materials.