Benefits of Using polyurethane screens in mining Operations

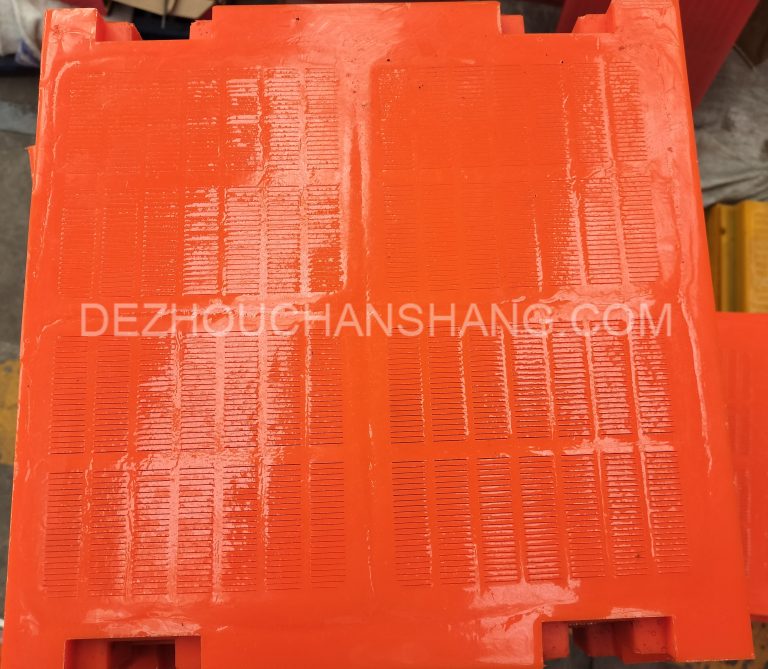

Mining operations require efficient and reliable equipment to ensure the extraction of valuable minerals. One crucial component of this equipment is the vibrating screen, which is used to separate materials based on size. In recent years, polyurethane screens have become increasingly popular in the mining industry due to their numerous benefits. Polyurethane screens are made from a synthetic material that offers several advantages over traditional steel screens. One of the main benefits of polyurethane screens is their durability. Unlike steel screens, which are prone to corrosion and wear, polyurethane screens are resistant to abrasion and can withstand harsh operating conditions. This durability translates to lower maintenance costs and longer screen life, making polyurethane screens a cost-effective option for mining operations. In addition to their durability, polyurethane screens also offer superior screening performance. The flexible nature of polyurethane allows for greater screening efficiency, as the material can conform to the shape of the particles being screened. This results in a higher screening capacity and improved separation of materials, leading to increased productivity and higher yields for mining operations. Another advantage of polyurethane screens is their ability to reduce noise levels during operation. The flexible nature of polyurethane absorbs vibrations and reduces noise, creating a quieter working environment for operators. This not only improves the overall working conditions but also enhances safety by reducing noise-related hazards in the workplace. Polyurethane screens are also lightweight and easy to install, making them a convenient option for mining operations. The lightweight nature of polyurethane screens reduces the strain on equipment and operators during installation and maintenance, saving time and labor costs. Additionally, polyurethane screens are easy to transport and handle, making them a practical choice for mobile mining operations. Furthermore, polyurethane screens are environmentally friendly, as they are recyclable and non-toxic. Unlike steel screens, which can release harmful chemicals into the environment, polyurethane screens are safe for both operators and the surrounding ecosystem. This makes polyurethane screens a sustainable option for mining operations looking to reduce their environmental impact.

Overall, the benefits of using polyurethane screens in mining operations are clear. From their durability and superior screening performance to their noise reduction and environmental friendliness, polyurethane screens offer a range of advantages that make them an ideal choice for mining operations. By investing in polyurethane screens, mining companies can improve efficiency, reduce costs, and create a safer and more sustainable working environment for their employees. In conclusion, polyurethane screens are a valuable asset for mining operations looking to optimize their screening processes. With their durability, screening performance, noise reduction, and environmental benefits, polyurethane screens offer a range of advantages that can help mining companies improve productivity and efficiency. By choosing polyurethane screens, mining operations can enhance their operations and achieve greater success in the extraction of valuable minerals.