صفحه های ترومل ویبراتور اورتان: مزایا و کاربردها

علاوه بر دوام و گزینه های سفارشی سازی، پانل های ترومل اورتان ویبراتور نصب و نگهداری آسان را ارائه می دهند. ساختار سبک وزن آنها حمل و نصب را ساده می کند و هزینه های نیروی کار و زمان نصب را کاهش می دهد. علاوه بر این، مواد یورتان در برابر خوردگی و آسیب های شیمیایی مقاوم است و باعث می شود پانل ها برای عملکرد طولانی مدت تمیز و نگهداری شوند.

راهنمای نهایی برای سفارشی سازی پنل های ترومل ویبراتور اورتان

The versatility of vibrator urethane trommel panels extends to their applications across various industries. These panels are commonly used in mining, quarrying, construction, and recycling operations for screening and separating bulk materials. In mining and quarrying, vibrator urethane trommel panels are employed to classify ore, aggregates, and other minerals based on size and composition.

In construction applications, these panels are utilized for sorting and grading construction aggregates, such as sand, gravel, and crushed stone. They help ensure the quality and consistency of construction materials, enhancing the performance of infrastructure projects.

Furthermore, vibrator urethane trommel panels play a crucial role in recycling facilities, where they are used to separate and classify recyclable materials, including paper, plastics, and metals. By efficiently segregating materials based on size and type, these panels facilitate the recycling process and contribute to waste reduction efforts.

Overall, vibrator urethane trommel panels offer a reliable and efficient solution for material screening and separation requirements across diverse industries. Their durability, customization options, ease of installation, and versatile applications make them indispensable components in processing operations seeking optimal performance and productivity.

In conclusion, vibrator urethane trommel panels combine durability, customization, and versatility to deliver superior screening performance in various industries. With their ability to withstand wear and tear, accommodate specific processing needs, and facilitate easy installation and maintenance, these panels represent a cost-effective solution for material separation applications. Whether in mining, construction, or recycling, vibrator urethane trommel panels play a crucial role in enhancing efficiency and productivity in screening operations.

The Ultimate Guide to Customizing Vibrator Urethane Trommel Panels

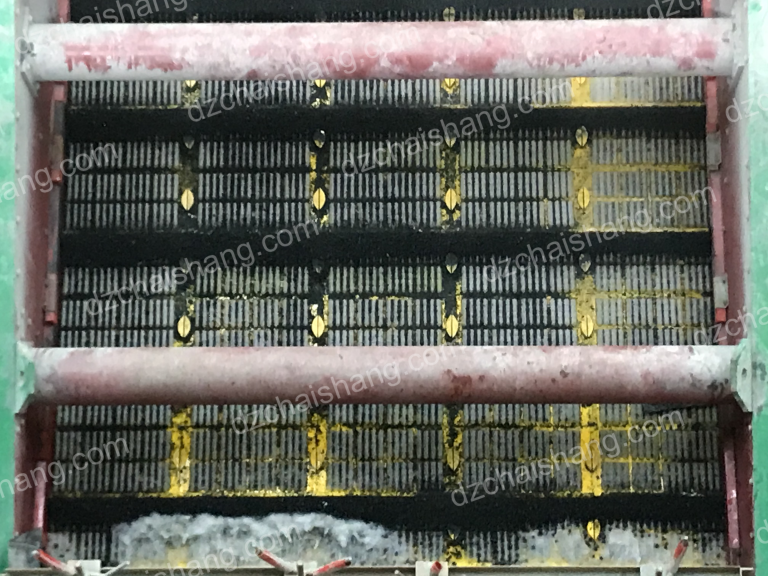

Vibrator urethane trommel panels play a crucial role in various industries, particularly in mining and aggregates processing. These panels are designed to withstand the rigorous conditions of screening operations, where they efficiently separate materials of different sizes. However, not all trommel panels are created equal, and customization options can significantly enhance their performance and longevity.

Customizing vibrator urethane trommel panels involves tailoring them to specific operational requirements, which can lead to improved efficiency and cost-effectiveness. One of the primary considerations in customization is the material composition of the panels. Urethane, known for its durability and abrasion resistance, is a popular choice for trommel panels. By adjusting the formulation of the urethane, manufacturers can fine-tune properties such as hardness, elasticity, and chemical resistance to suit the application’s demands.

Furthermore, customization extends to the design and dimensions of the trommel panels. Different screening applications may require panels of varying sizes, shapes, and aperture configurations to achieve optimal results. Customization allows for precise matching of panel dimensions to the trommel’s specifications, ensuring seamless integration and maximum screening efficiency.

In addition to size and material, customization options for vibrator urethane trommel panels include features such as reinforced edges, modular designs, and specialized coatings. Reinforced edges help prevent premature wear and tear, prolonging the lifespan of the panels and reducing maintenance costs. Modular designs allow for easy installation and replacement of individual panels, minimizing downtime during maintenance procedures.

Specialized coatings, such as anti-clogging or anti-static treatments, can also be applied to vibrator urethane trommel panels to address specific operational challenges. These coatings help prevent material buildup and blinding, ensuring uninterrupted screening performance even in difficult operating conditions.

Moreover, customization may involve incorporating innovative technologies into trommel panel design, such as embedded sensors for real-time monitoring of panel wear and performance. By gathering data on panel usage and wear patterns, operators can optimize maintenance schedules and anticipate replacement needs, further enhancing operational efficiency and cost savings.

When considering customization options for vibrator urethane trommel panels, collaboration with experienced manufacturers and suppliers is essential. These experts can provide valuable insights into material selection, design optimization, and application-specific requirements, ensuring that the customized panels meet performance expectations and deliver tangible benefits to the operation.

In conclusion, customizing vibrator urethane trommel panels offers a myriad of benefits for screening operations across various industries. By tailoring material composition, design, and features to specific requirements, operators can enhance screening efficiency, reduce downtime, and lower maintenance costs. Collaboration with knowledgeable suppliers is key to realizing the full potential of customization options and optimizing the performance of vibrator urethane trommel panels in demanding applications.