کاوش در عملکرد و کاربرد صفحات غربال کششی

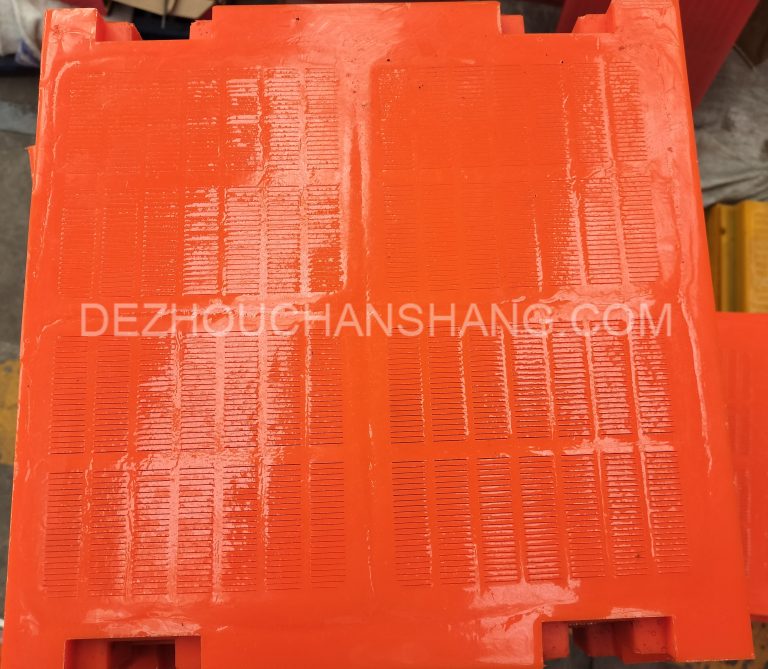

صفحات الک کششی، پانل های مشبک ظریف و صفحات غربال سنگدانه اجزای جدایی ناپذیر در فرآیندهای مختلف صنعتی هستند. این ابزارها برای تسهیل جداسازی، طبقه بندی و اندازه مواد مختلف طراحی شده اند و در نتیجه کارایی و بهره وری را در بخش های متعدد افزایش می دهند. هدف این مقاله بررسی عملکرد و کاربرد این ابزار ضروری است و درک جامعی از نقش آنها در صنایع مختلف ارائه میکند. . آنها معمولاً از فولاد با کشش بالا یا فولاد ضد زنگ ساخته می شوند که دوام و طول عمر آنها را تضمین می کند. کشش صفحه الک بسیار مهم است زیرا مستقیماً بر دقت فرآیند الک تأثیر می گذارد. یک صفحه الک با کشش خوب تضمین می کند که مواد الک شده به طور مساوی در سطح توزیع می شوند و در نتیجه نتایج ثابت و قابل اعتمادی را ارائه می دهند. . این امکان جداسازی ذرات بسیار ریز را فراهم می کند و آن را برای صنایعی که نیاز به الک دقیق و دقیق دارند ایده آل می کند. پانل مش ریز معمولاً در صنایع غذایی و دارویی استفاده می شود، جایی که به جداسازی پودرهای ریز و گرانول ها کمک می کند. همچنین در صنایع شیمیایی برای جداسازی مواد شیمیایی ریز و در صنایع معدنی برای طبقه بندی مواد معدنی استفاده می شود. برای طبقه بندی و اندازه گیری انواع سنگدانه ها مانند ماسه، شن و سنگ خرد شده استفاده می شود. پانل غربال سنگدانه معمولاً از فولاد با کشش بالا ساخته می شود تا در برابر ماهیت ساینده سنگدانه ها مقاومت کند. دارای اندازه مش بزرگی است که اجازه عبور ذرات بزرگ را می دهد و در نتیجه جداسازی اندازه های مختلف سنگدانه ها را تسهیل می کند. همچنین در صنعت ساخت و ساز برای جداسازی مصالح ساختمانی، در صنعت مدیریت پسماند برای تفکیک مواد زائد و در صنعت کشاورزی برای جداسازی دانه ها و دانه ها استفاده می شود.

In conclusion, tensioned sieve plates, fine mesh panels, and aggregate sieve panels play a crucial role in various industries. They facilitate the separation, classification, and sizing of different materials, thereby enhancing efficiency and productivity. Their durability, versatility, and customizability make them an invaluable tool in any industrial process that involves sieving. As industries continue to evolve and demand more efficient and precise sieving solutions, the importance of these tools is set to increase even further.

Understanding the Importance of Fine Mesh Panels in Industrial Applications

Understanding the importance of fine mesh panels in industrial applications requires a deep dive into the world of industrial sieving and filtration. These processes are integral to many industries, including mining, agriculture, pharmaceuticals, and food processing. The key to these processes is the use of tensioned sieve plates, fine mesh panels, and aggregate sieve panels.

Tensioned sieve plates are a type of industrial sieve that is designed to withstand high levels of tension. These plates are typically made from durable materials such as stainless steel or polyurethane, which can resist the wear and tear of industrial processes. The tension in these plates allows for a high degree of precision in the sieving process, ensuring that only particles of a certain size can pass through. This is particularly important in industries such as mining, where the separation of valuable minerals from unwanted material is crucial.

Following the tensioned sieve plates, we have the fine mesh panels. These panels are designed with a very tight weave, allowing for the filtration of very small particles. The size of the openings in the mesh can be adjusted to suit the needs of the specific application, making these panels incredibly versatile. In the pharmaceutical industry, for example, fine mesh panels are used to filter out impurities during the production of medications. This ensures that the final product is pure and safe for consumption.

Finally, we have the aggregate sieve panels. These panels are designed to handle larger particles and are often used in the construction and agriculture industries. In construction, aggregate sieve panels are used to separate different sizes of aggregate for use in concrete and asphalt. In agriculture, these panels are used to separate grain from chaff during the harvesting process.

The importance of these panels in industrial applications cannot be overstated. They allow for the efficient and effective separation of materials, which is crucial in many industries. Without these panels, the process of separating materials would be much more labor-intensive and less precise.

Moreover, these panels also contribute to the sustainability of industrial processes. By allowing for the precise separation of materials, they reduce waste and increase efficiency. This not only saves companies money but also reduces their environmental impact.

In addition, these panels are designed to be durable and long-lasting. This means that they do not need to be replaced as often as other types of industrial equipment, which can also save companies money in the long run.

In conclusion, tensioned sieve plates, fine mesh panels, and aggregate sieve panels play a crucial role in many industrial applications. They allow for the precise and efficient separation of materials, contribute to the sustainability of industrial processes, and are designed to be durable and long-lasting. As such, they are an essential piece of equipment for many industries. Understanding their importance can help companies make informed decisions about their industrial processes and equipment choices.